Imitated Song-Dynasty Ge-kiln crackle-glaze celadon and manufacturing technique thereof

A manufacturing process and celadon technology, which is applied to the formulation and manufacturing process of celadon sliced imitating Ge kiln in the Song Dynasty, can solve problems such as unsatisfactory effects, and achieve the effect of better gloss and fine texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A celadon formula imitating Ge Kiln in the Song Dynasty, including tire material and glaze, wherein: the tire material is made of the following raw materials in parts by weight: 80 parts of Zijin clay, 18 parts of Xiyuan porcelain clay, and 15 parts of Huangtan porcelain clay The glaze is made of the following raw materials in parts by weight: 32 parts of linggen glaze soil, 24 parts of quicklime, 5 parts of quartz, 5 parts of pyrite, 13 parts of big kiln purple gold soil, and 22 parts of yellow fluorite.

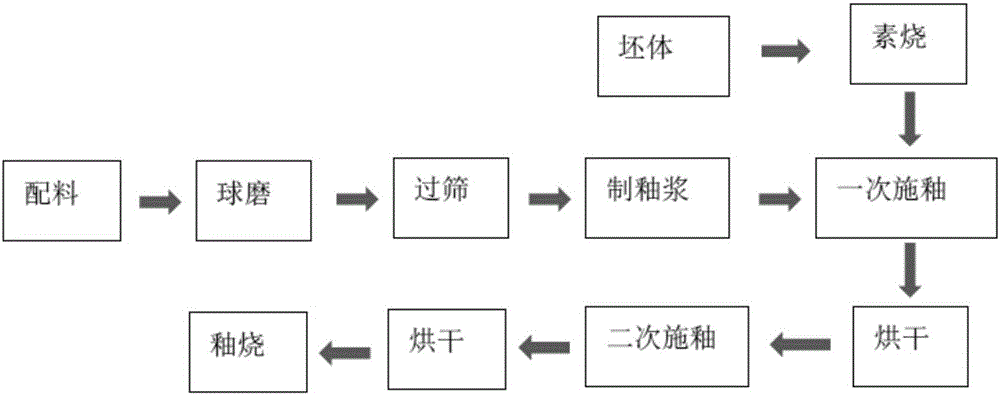

[0022] A kind of celadon manufacturing process of Ge Kiln, the process is as follows figure 1 shown, including the following steps:

[0023] A. Firing the biscuit: mix all the raw materials of the tire material with water evenly to make a mud, after molding and drying the mud, put it into a kiln for firing to make a biscuit;

[0024] B. Preparation of ceramic glaze: mix the raw materials in the glaze according to the proportion, after pulverization, add water ball m...

Embodiment 2

[0030] A celadon formula imitating Ge Kiln of the Song Dynasty, including tire material and glaze, wherein: the tire material is made of the following raw materials in parts by weight: 90 parts of Zijin clay, 15 parts of Xiyuan porcelain clay, and 20 parts of Huangtan porcelain clay The glaze is made of the following raw materials in parts by weight: 35 parts of lingen glaze soil, 20 parts of quicklime, 3 parts of quartz, 3 parts of pyrite, 11 parts of big kiln purple gold soil, and 25 parts of yellow fluorite. Ge kiln open piece celadon manufacturing process is the same as embodiment 1.

Embodiment 3

[0032] A celadon formula imitating Ge Kiln of the Song Dynasty, including tire material and glaze, wherein: the tire material is made of the following raw materials in parts by weight: 85 parts of Zijin clay, 16 parts of Xiyuan porcelain clay, and 18 parts of Huangtan porcelain clay The glaze is made of the following raw materials in parts by weight: 34 parts of lingen glaze soil, 22 parts of quicklime, 3 parts of quartz, 5 parts of pyrite, 12 parts of big kiln purple gold soil, and 24 parts of yellow fluorite. Ge kiln open piece celadon manufacturing process is the same as embodiment 1.

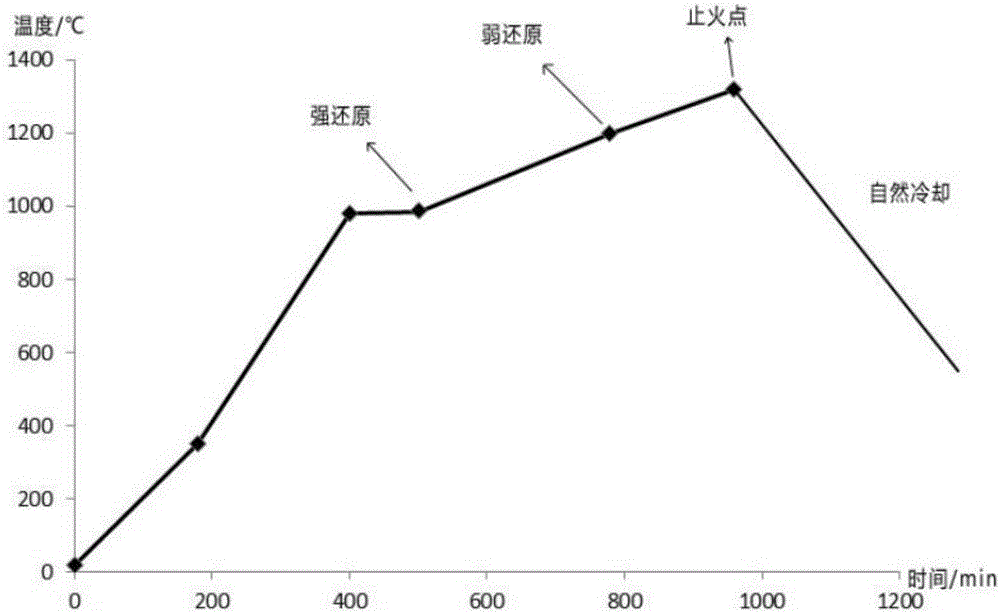

[0033] The present invention has prepared the celadon body material of the Heitai Ge kiln split pieces through multiple experiments. This type of body material has good molding performance and appears black when fired at 1300°C-1320°C. In order to produce celadon with a glazed surface effect similar to that of Heitai Ge kiln in the Southern Song Dynasty, a reasonable formula was obtained thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com