Producing system and method for mixed-braiding unidirectional fabric

A production system, unidirectional fabric technology, applied in the field of mixed unidirectional fabric production system, can solve problems such as unreasonable arrangement position, long repair time, affecting fabric quality, etc., achieve fast and convenient splicing, reduce unnecessary Necessary wear, effect of reducing trace length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

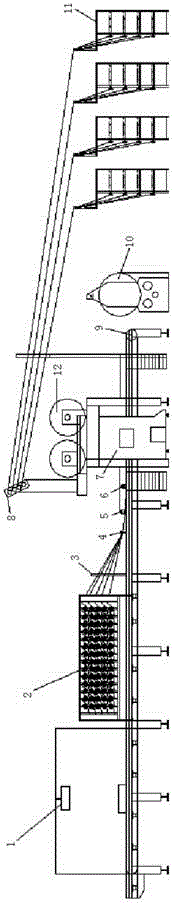

[0038] Embodiment: a kind of production system of mixed weaving unidirectional fabric, its structure is as figure 1 shown, including:

[0039] Stitch-bonding machine 7, the left side of the stitch-bonding machine 7 is provided with pressing roller 6, pressing roller 5, pressing roller 4, dividing reed 3, carbon fiber warp creel 2 and weft laying device 1 successively;

[0040] The right side of the sewing machine 7 is provided with a pulling roller 9, a fabric frame 10 and a glass fiber warp frame 11;

[0041] The top of the sewing machine 7 is provided with a pan head 12 and a roller 8;

[0042] in,

[0043] There are 4 groups of the glass fiber warp creels 11; the height of the rollers 8 is higher than the pan head 12 and the glass fiber warp crenels 11.

[0044] As a preferred option, the fabric rack 10 includes a main support, on which there is a reel, and the reel is driven by a motor.

[0045] At the same time, in order to further reduce the abrasion of carbon fiber,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com