Method for strengthening subgrade basement of existing high speed railway line

A technology for high-speed railways and existing lines, applied in roads, infrastructure engineering, soil protection, etc., can solve problems such as insufficient reinforcement strength, uneven reinforcement, settlement or collapse, etc., to improve soil strength and change physical and mechanical properties and the ability to bear loads, and the effect of reducing soil deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The method for reinforcing the existing track base of the high-speed railway according to the present invention will be explained in detail below in conjunction with the accompanying drawings.

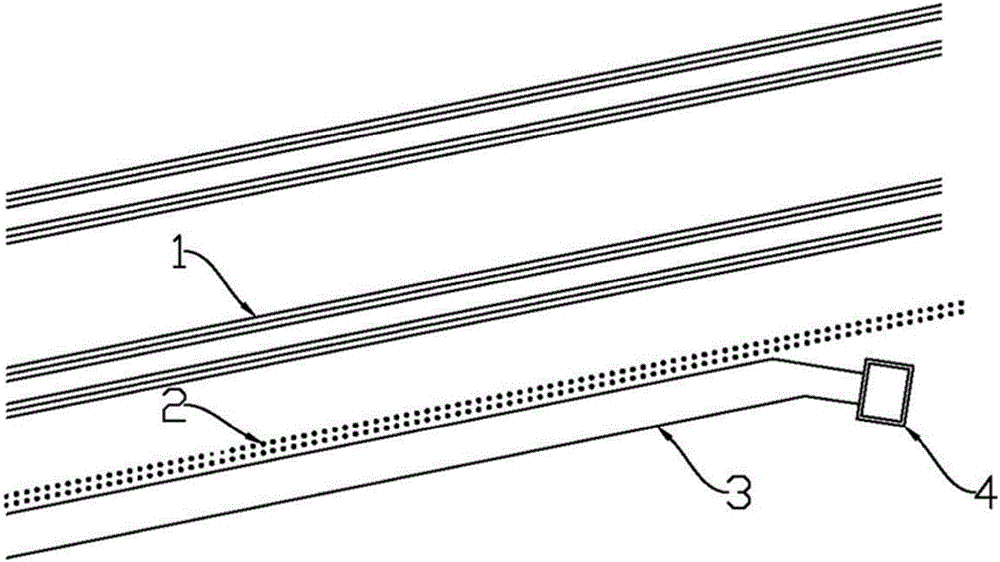

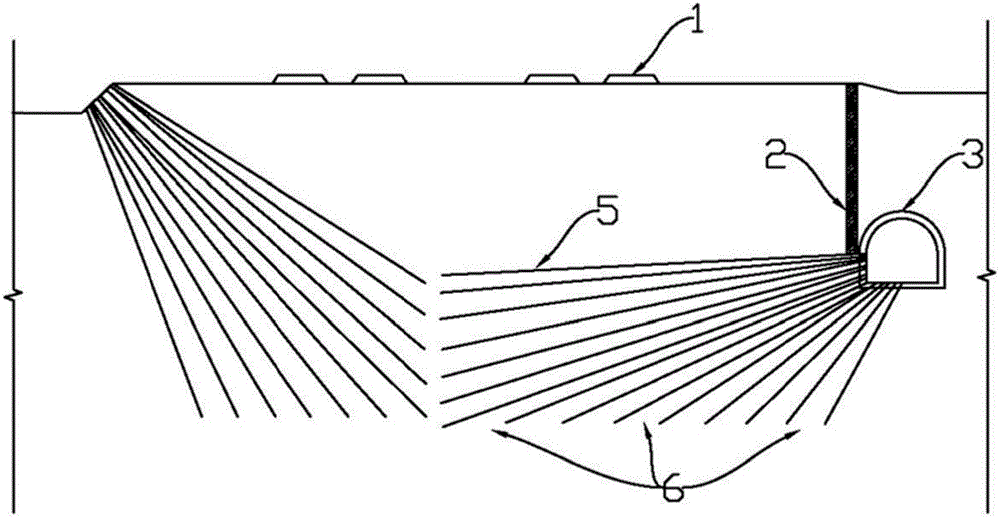

[0038] In general, this example presents the reinforcement construction of the existing roadbed of the high-speed railway when the shield tunneling of the subway section 00 of Beijing Metro Line 14 passes through the Beijing-Tianjin intercity railway. The sequence is as follows: Excavate a temporary vertical shaft 4, excavate and support the horizontal channel 3 with a length of 76.289m from the vertical shaft to the west along the outer side of the Beijing-Tianjin intercity high-speed railway line 1, and grout the test section from the south side wall in the horizontal channel 3. The reinforcement test The length of the section is 19.65m, the width is 16m, and the thickness is 8.9m. After the grouting in the test section is completed, the grouted soil is drilled and cored. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com