A method of manufacturing a supporting platform for a distribution machine based on a climbing formwork platform

A technology for supporting a platform and a manufacturing method, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, processing of building materials, etc., can solve the hidden safety hazards, increase labor costs, and increase tower crane cranes in hoisting and placing machines. It can reduce the construction workload, ensure reliable quality, and reduce potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

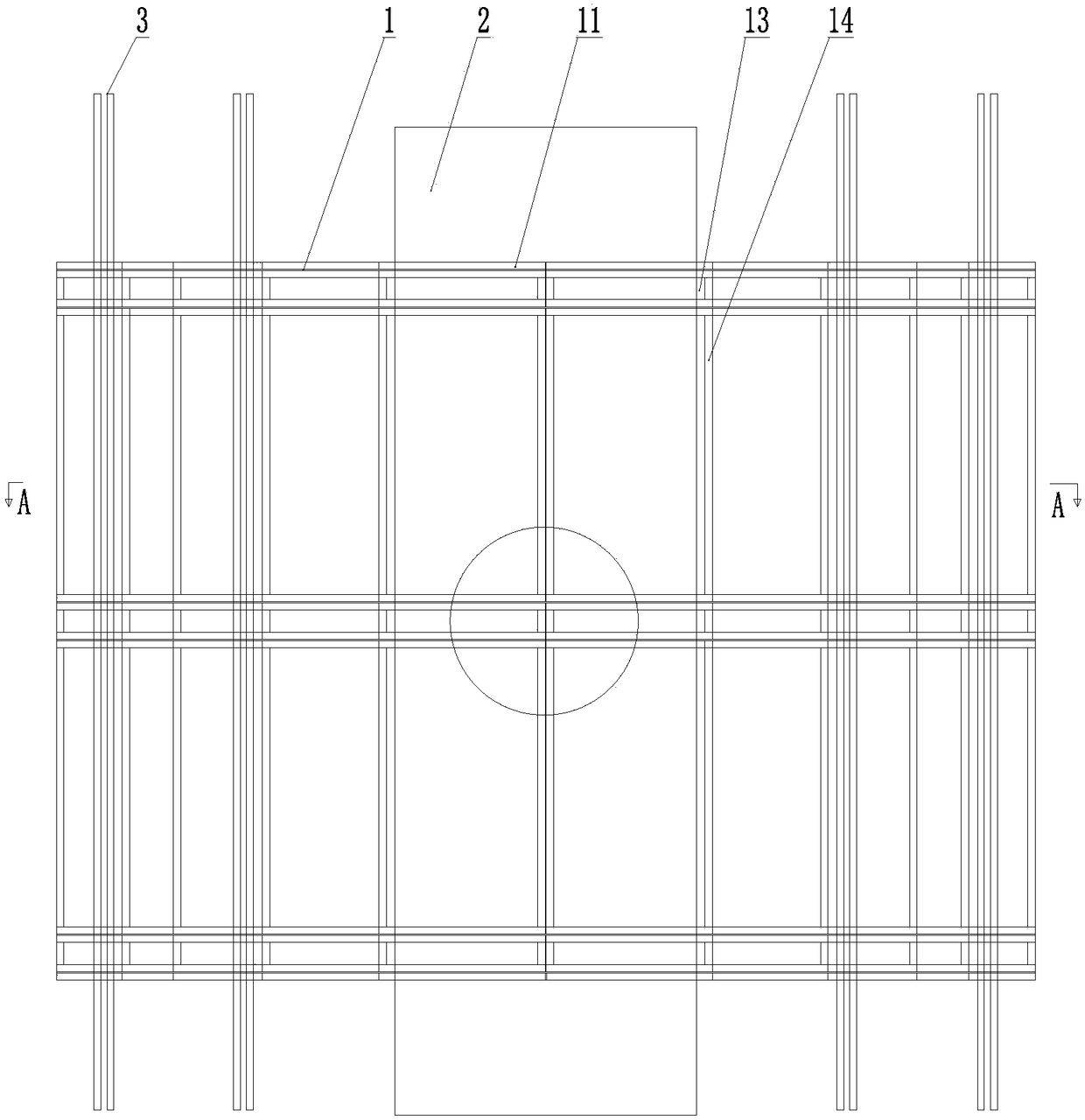

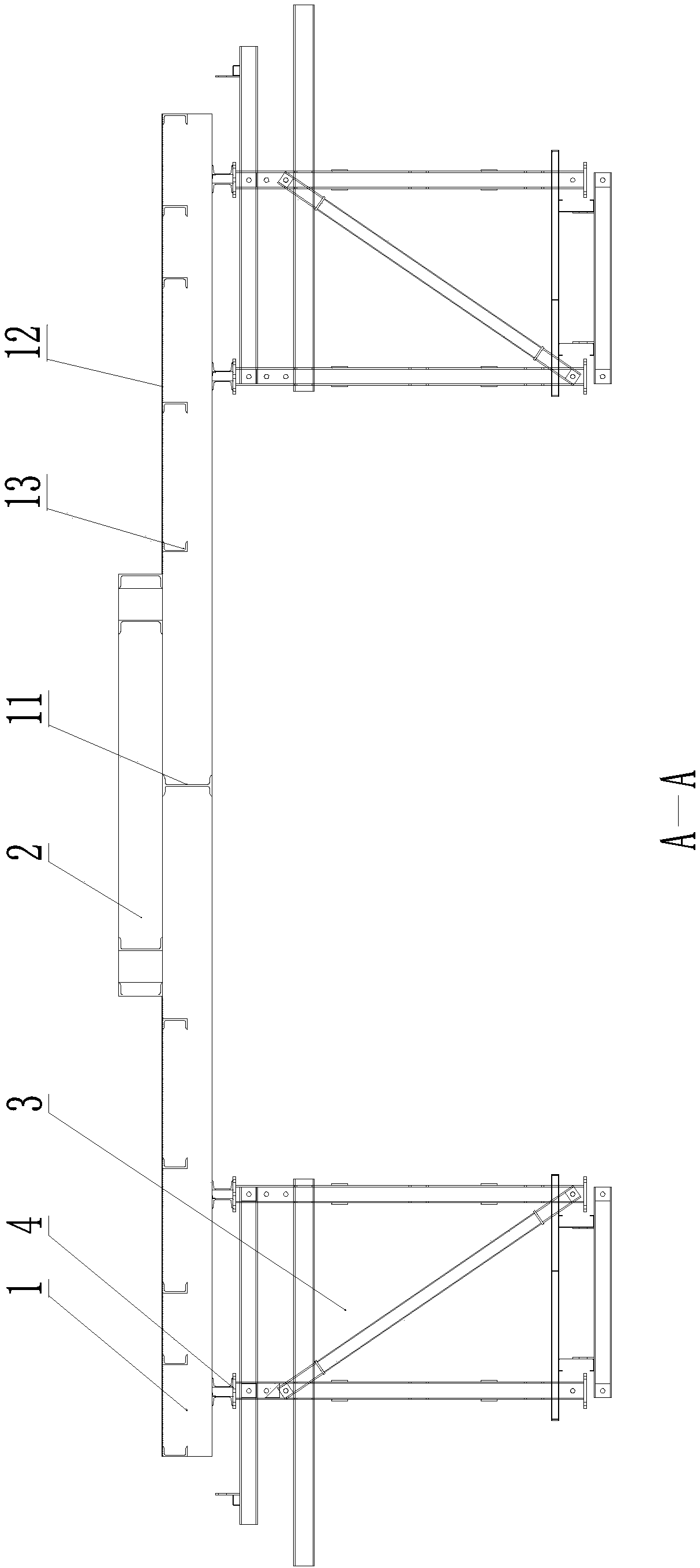

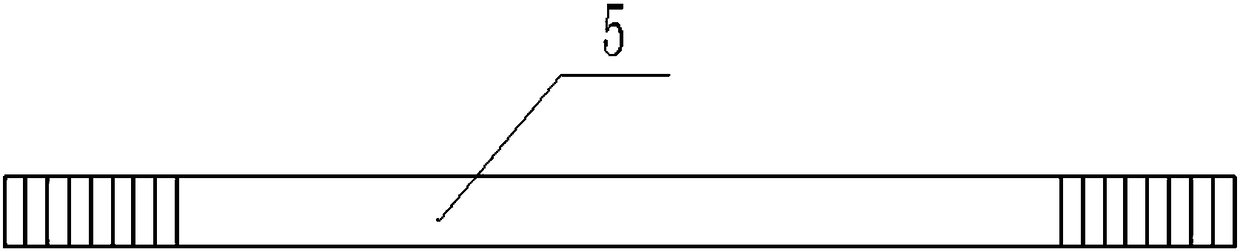

[0028] Such as Figure 1 to Figure 3 As shown, the distribution machine support platform of a climbing formwork platform provided by the present invention includes a distribution machine base 2, a steel structure platform 1 and a plurality of climbing formwork lifting frames 3, and the distribution machine base 2 is fixedly arranged on the upper part of the steel structure platform 1 , a plurality of climbing formwork lifting frames 3 are fixedly arranged on the lower part of the steel structure platform 1, and the steel platform is 2.5m higher than the operation layer, which does not affect the construction of the operation layer. The steel structure platform 1 includes pattern steel plates 12 and six I-beams 11, six The I-beams 11 are arranged side by side in parallel, and every two I-beams 11 are fixedly connected by a plurality of channel st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com