Motor Cooling Device and Cooling and Lubricating System of Power Coupling Mechanism

A power coupling and motor cooling technology, which is applied in the direction of electromechanical devices, cooling/ventilation devices, transmission parts, etc., can solve the problems of low utilization rate of cooling oil, large space occupied by motors, complex shell structure, etc., and improve output utilization rate , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

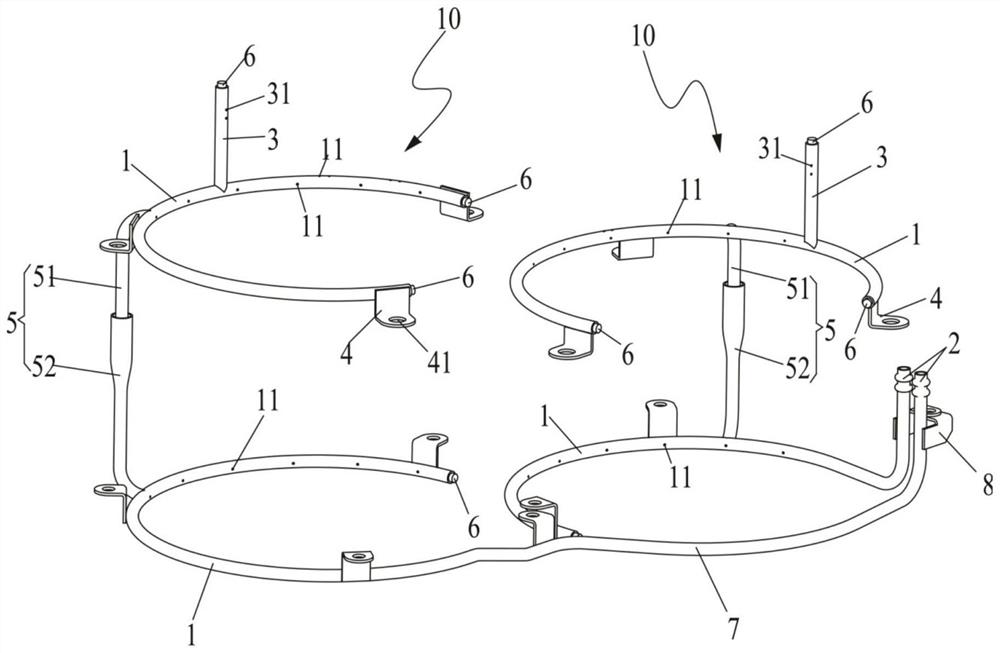

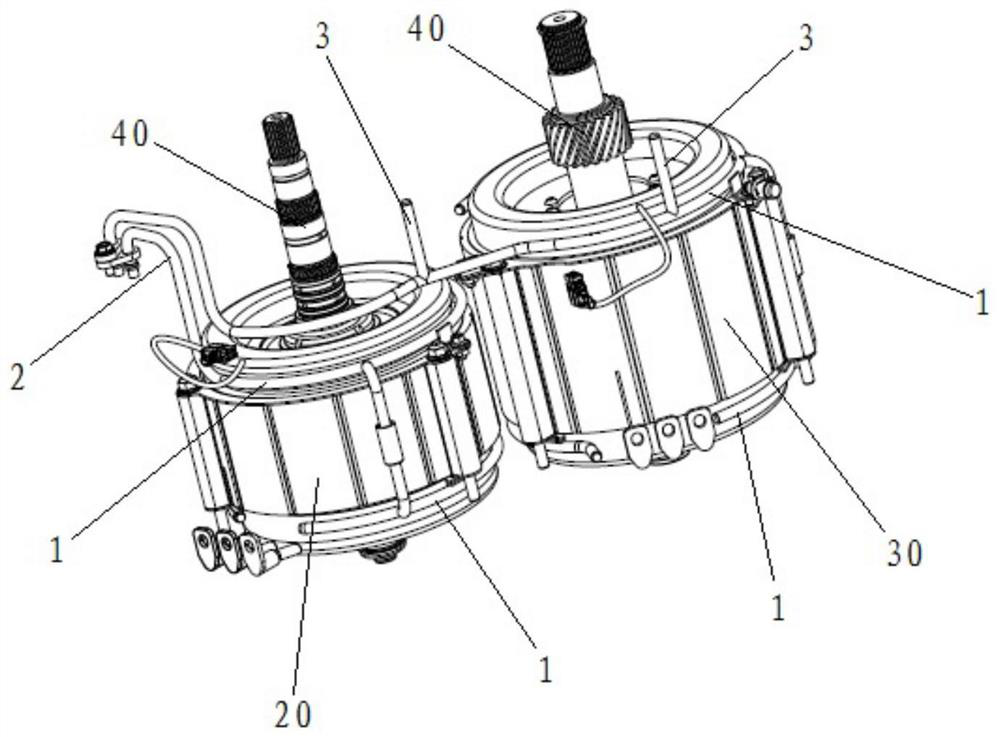

[0020] like figure 1 As shown, the motor cooling device of the power coupling mechanism of the embodiment of the present invention includes at least one liquid spray pipe assembly 10 for spraying coolant to cool the motor, and each liquid spray pipe assembly 10 includes at least two surrounding motor outer contours The liquid spray ring pipe 1 provided, each liquid spray pipe assembly 10 is provided with an independent liquid infusion end 2, and the liquid spray ring pipe 1 of the liquid spray pipe assembly 10 is not communicated with the liquid spray ring pipe 1 of other liquid spray pipe assemblies 10 , that is, the cooling liquid in each liquid spray pipe assembly 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com