Caulking fixation type power element and expansion valve using the same

A technology of power components and riveting, which is applied in the field of expansion valves, can solve problems such as the protruding and exposed opening of the connecting part 3, the damage durability of the diaphragm 2, and the lowering of the diaphragm 2, so as to simplify the positioning action, suppress deformation, and prevent damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

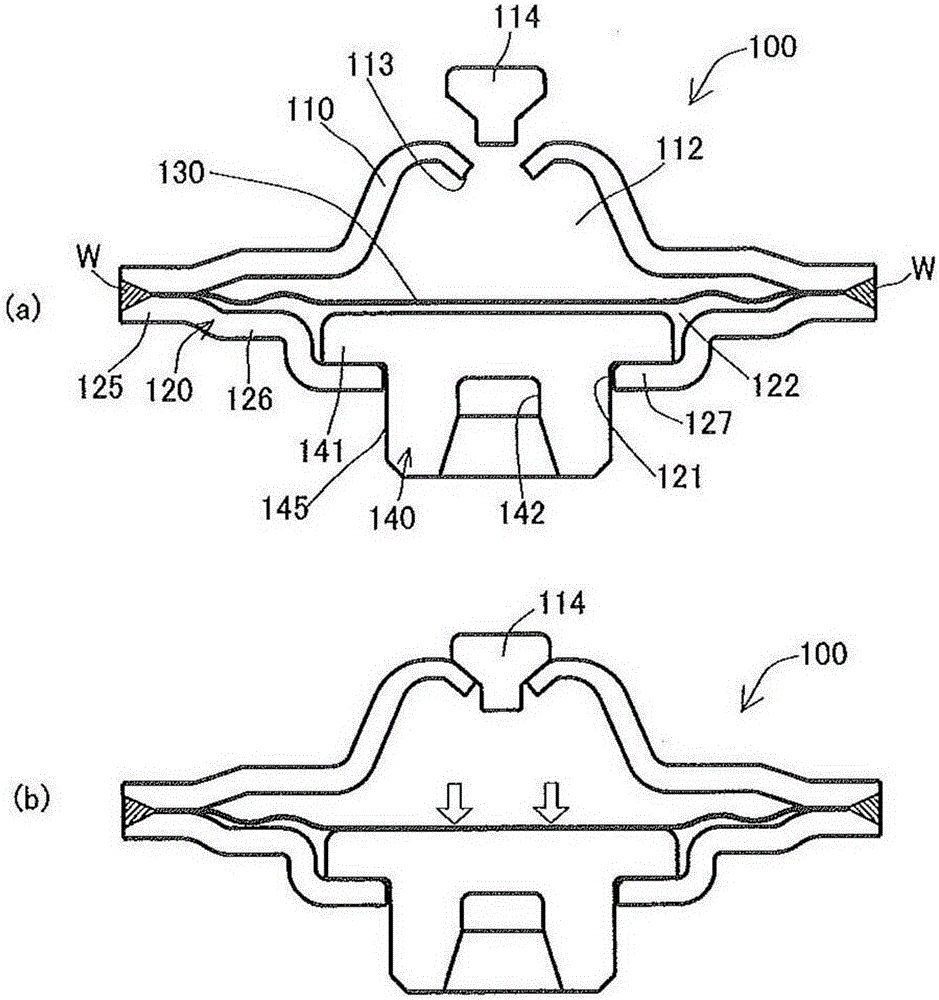

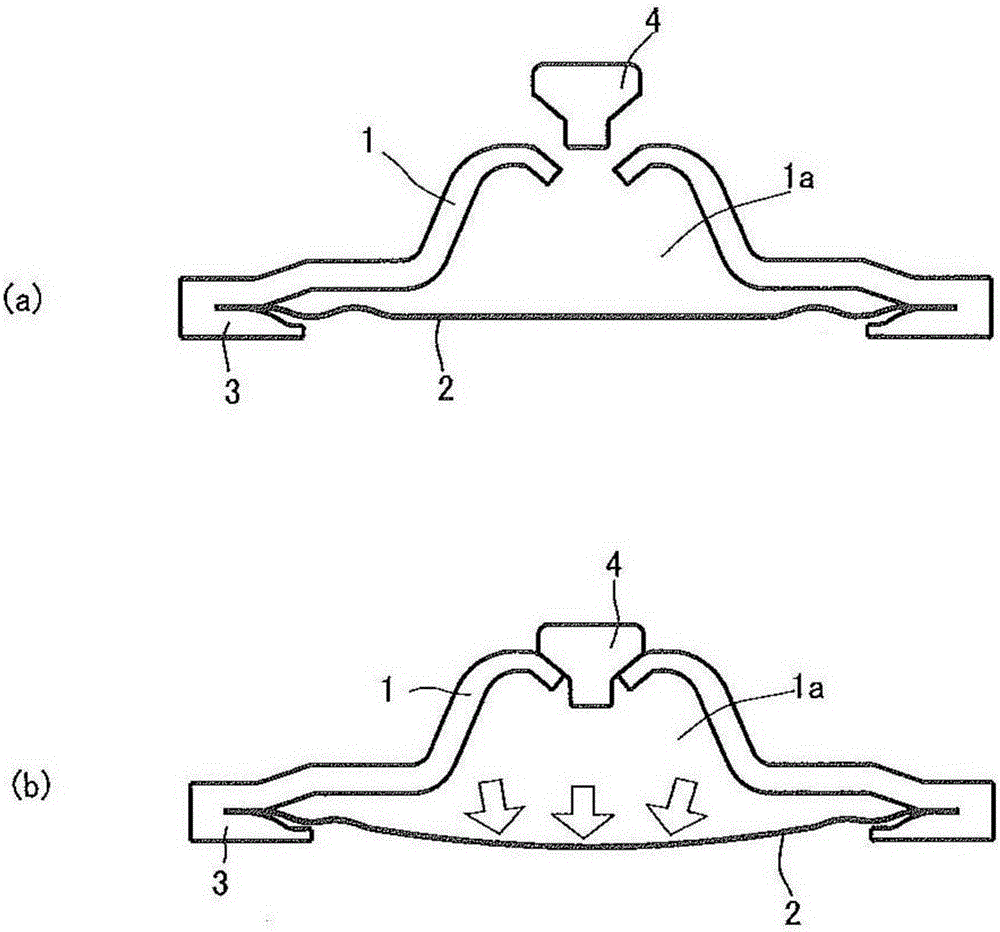

[0068] figure 1 It is a longitudinal sectional view showing the structure of an embodiment of the riveted power element of the present invention, figure 1 (a) represents the state before the working gas is sealed, figure 1 (b) shows the state after the working gas is sealed.

[0069] Such as figure 1 As shown in (a), the riveted fixed power element 100 is composed of an upper cover member 110, a receiving member 120 having a through hole 121 in the center, a diaphragm 130 sandwiched between the upper cover member 110 and the receiving member 120, and a receiving member 120 from the receiving member 120. The through hole 121 of the stop member 140 is formed.

[0070] A pressure chamber 112 is formed inside between the upper cover member 110 and the diaphragm 130 . In addition, a working gas such as an inert gas is sealed in the pressure working chamber 112 .

[0071] Here, a sealing hole 113 for sealing the above-mentioned working gas is formed in the central part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com