Rotary kiln valve set platform CO detection apparatus and method

A detection device and rotary kiln technology, which is applied in the field of rotary kiln, can solve the problems of inability to judge the location of air leakage point and small monitoring range, and achieve the effect of reducing the scope of maintenance, reducing labor intensity and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

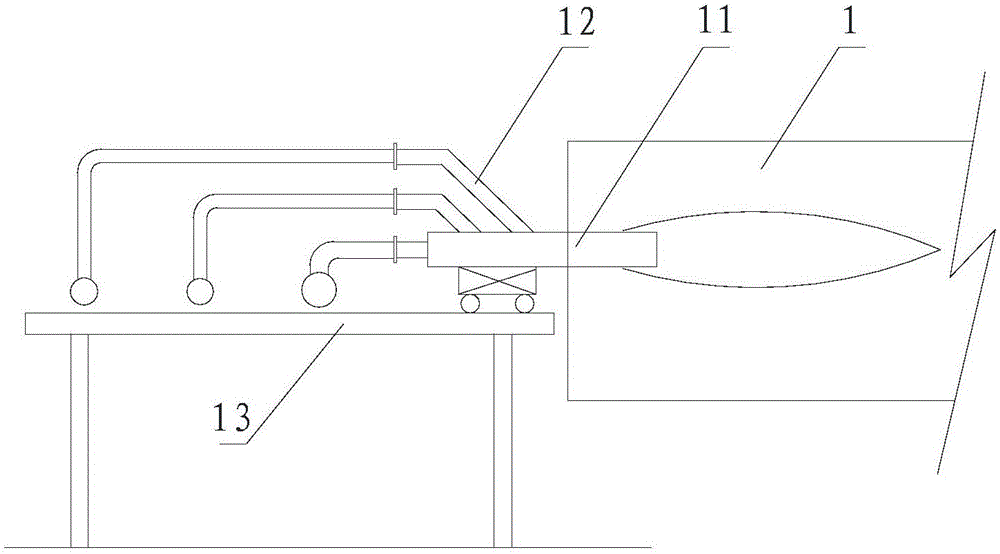

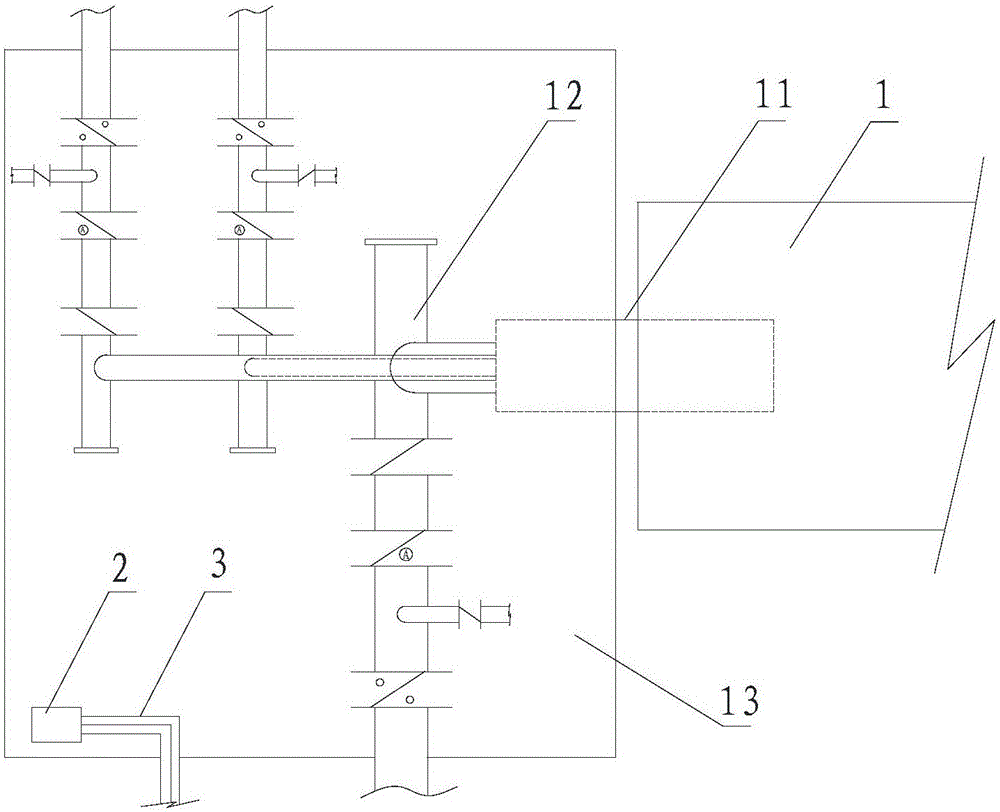

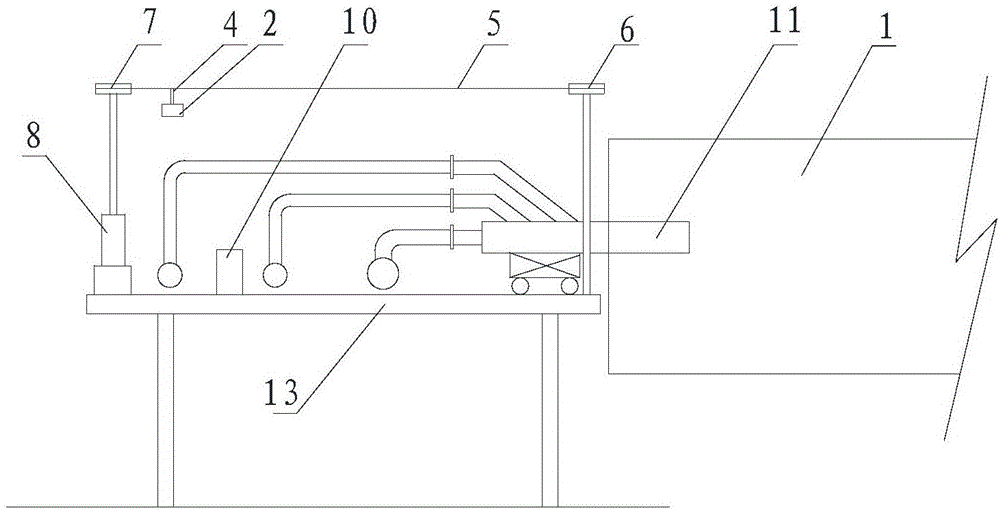

[0047] For the CO detection device of the rotary kiln valve group platform in the first embodiment, please refer to image 3 , the closed circuit is located above the valve group platform 13 . The CO detector 2 is installed under the closed circuit, and the closed circuit drives the CO detector to move cyclically on the valve group platform 13 . Obviously, since the CO detector 2 moves along with the closed circuit, the CO detector 2 is a CO wireless detector, and the cables and cable bushings can be omitted, which not only saves space on the furnace top, but also reduces the possibility of operating problems. Hazard of tripping over cable glands and falling.

[0048] When the CO wireless detector is hung under the closed circuit, the CO wireless detector is closer to the valve group platform 13, so that the CO concentration at each position on the valve group platform 13 can be accurately monitored. Among them, preferably but not necessarily image 3 As shown in the figure...

Embodiment 2

[0060] The difference from the first embodiment is that the closed route of the second embodiment is triangular, so that the closed route drives the CO wireless detector to move circularly along the triangular loop, please refer to Figure 6 .

[0061] On this basis, the number of driving sprocket 7 in the second embodiment is one, and the number of driven sprocket 6 is two, and they are distributed in three corner positions.

[0062] In the above embodiments, the locator can be in the form of a limit switch 9 . Specifically, when the CO wireless detector passes the set position, the limit switch 9 is turned on, and the limit switch 9 sends a trigger signal to the controller, and the controller receives the trigger signal The timing of the signal and the speed at which the closed line moves calculate the real-time position of the CO wireless detector.

[0063] see further Figure 6 , when the CO detector 2 passes above the limit switch 9, the CO detector 2 presses the limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com