Constant torque intelligent control device and operation method for billet cutting process

An intelligent control and constant torque technology, applied in program control, electrical program control, digital control, etc., can solve problems such as frequent alarms of equipment with variable range, impact of equipment and saw blades, and increased loss rate of billet saw blades, etc., to achieve Reduce equipment off-line maintenance costs, stabilize equipment operation power, and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

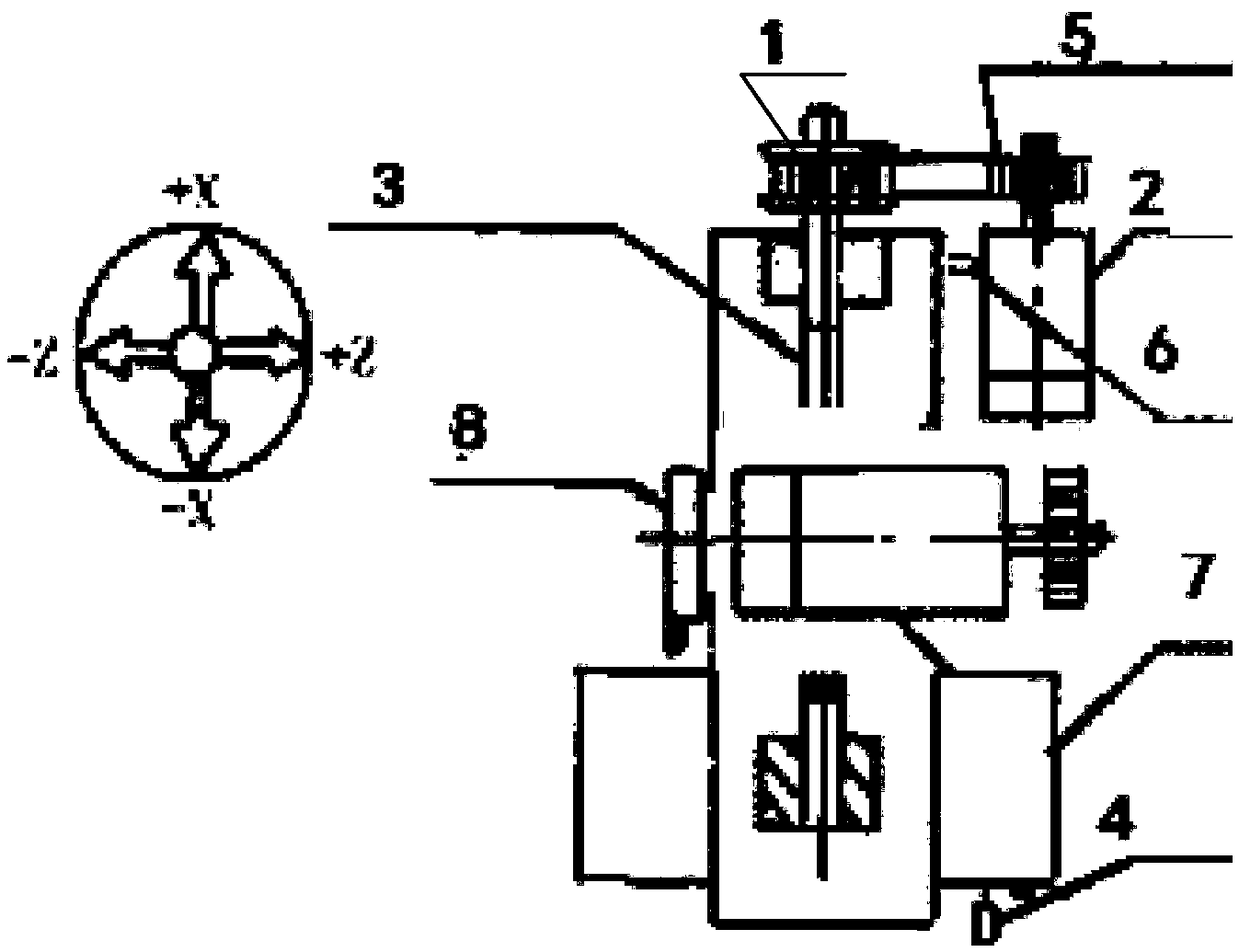

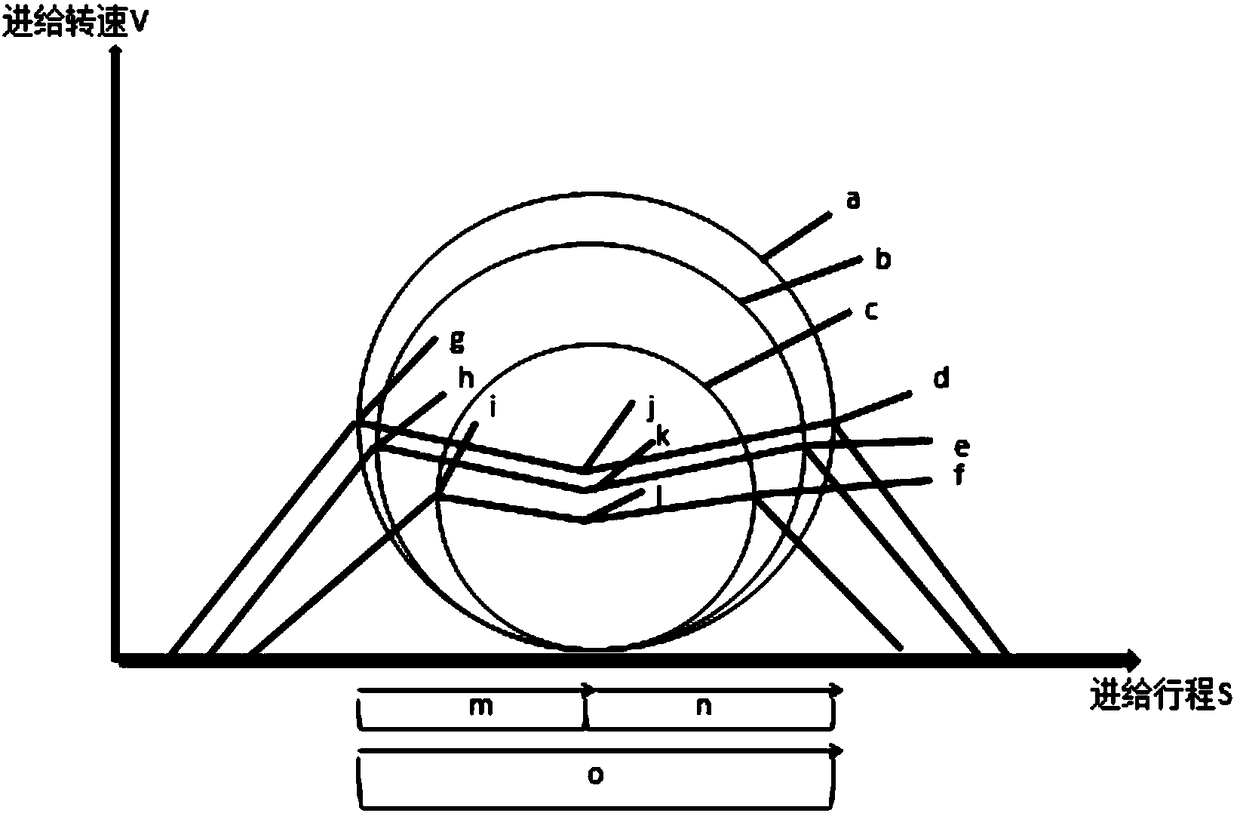

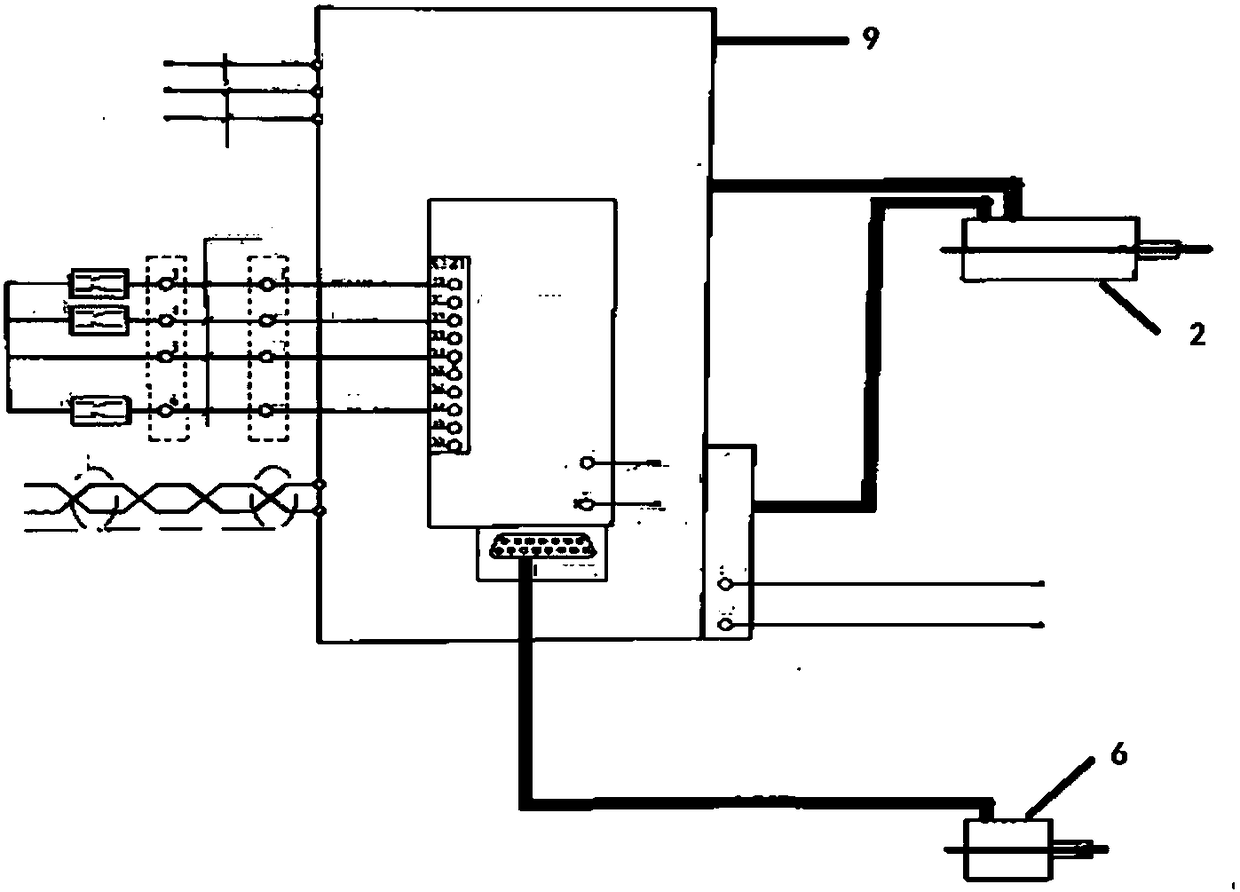

[0024] The constant torque intelligent control device and operation method of the billet cutting process of the present invention will be described in conjunction with the accompanying drawings.

[0025] The design concept of the constant torque intelligent control device and operation method of the billet cutting process of the present invention is based on the fact that during the billet cutting process, the feed motor speed is gradually reduced according to the diameter of the billet, and the purpose is to reduce the torque fluctuation of the motor during the sawing process , the current fluctuation will be stable, so as to protect the equipment and reduce the loss of the saw blade. The significance of this digital-analog control is that when the sawing speed cannot be adjusted due to the solidification of the module program in the transmission aspect, the control mathematical model is built in the PLC program, and then the sawing speed can be adjusted in a large range. Req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com