Ship sectional construction workshop operation scheduling system and scheduling method thereof

A technology for segmented construction and job scheduling, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as poor process similarity, low site resource utilization, and low level of intelligence in segmented construction operation scheduling management. Achieve the effect of compressing segmented construction period, improving site utilization, intelligent process guidance and management planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

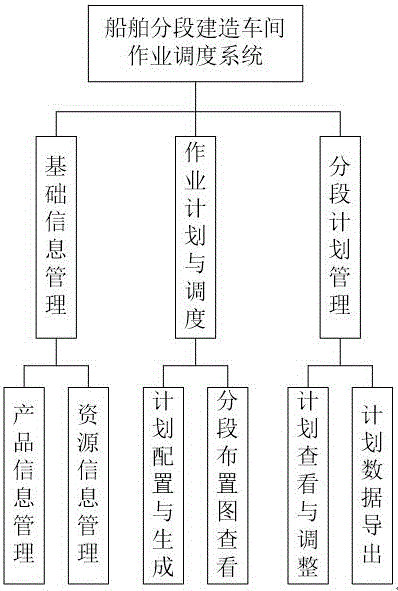

[0038] Such as figure 1 , a ship block construction workshop operation scheduling system, including: a basic information management module, an operation planning and scheduling module, a block plan management module, and the like.

[0039] The basic information management module is the input and output interface of the system database, including two sub-modules of product information management and resource information management. view and modify, etc.;

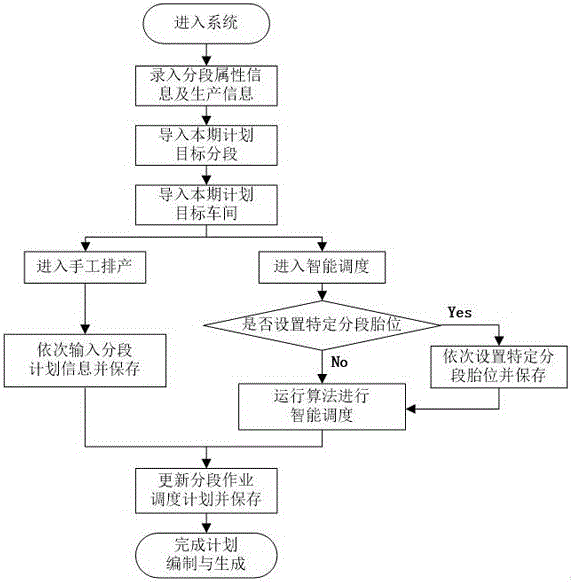

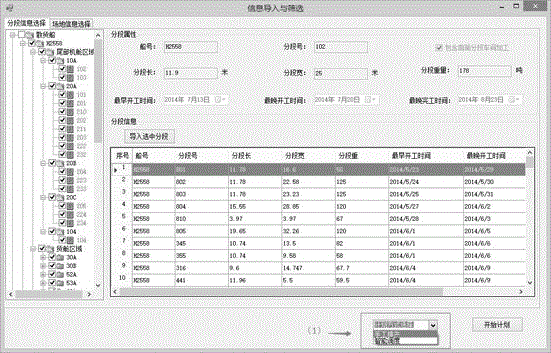

[0040] The job planning and scheduling module is the realization module of the planning and generation function, including two sub-modules of plan configuration and generation and section layout view, and the target section and site information are imported through the plan configuration and generation sub-module, and manual scheduling or Intelligen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com