Contact finger sheet, contact finger sheet processing method and contact finger, contact finger assembly, circuit breaker

A finger-to-finger and finger-to-finger technology, applied in circuit breaker parts, circuit breaker contacts, circuits, etc., can solve the problem of high processing and manufacturing costs of the contact finger sheet, improve material utilization, reduce manufacturing costs and production costs The effect of the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

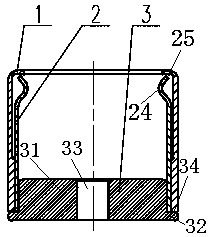

[0031] Example of a circuit breaker:

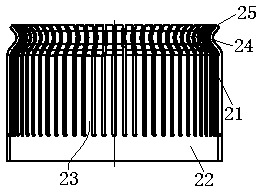

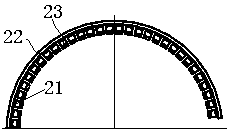

[0032] The circuit breaker includes an energized conductor 6 and a contact finger assembly installed on the energized conductor 6. The electrical connection or de-energization of the energized conductor 6 is realized through the plug-in fit of the contact finger assembly. The specific structure of the circuit breaker is as follows: Figure 1~Figure 4 shown. The contact finger assembly includes a step-shaped contact seat 3 composed of two concentric cylinders. The middle part of the contact seat 3 is provided with a bolt perforation 33 for connecting with the corresponding threaded hole on the current conductor 6. The contact seat 3 is fixedly connected by a bolt 5. energized conductor 6. The diameter of the upper cylinder 31 of the contact seat 3 is smaller, and the diameter of the lower cylinder 32 is larger. The upper end surface of the lower cylinder beyond the upper cylinder forms a shoulder 34 of the contact seat 3, and the shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com