Double-stator and barrel-type permanent magnet rotor accelerator with closed cycle multi-channel counterflow cooling

A counter-current cooling, closed-cycle technology, applied in magnetic circuit rotating parts, cooling/ventilation devices, magnetic circuit shape/style/structure, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

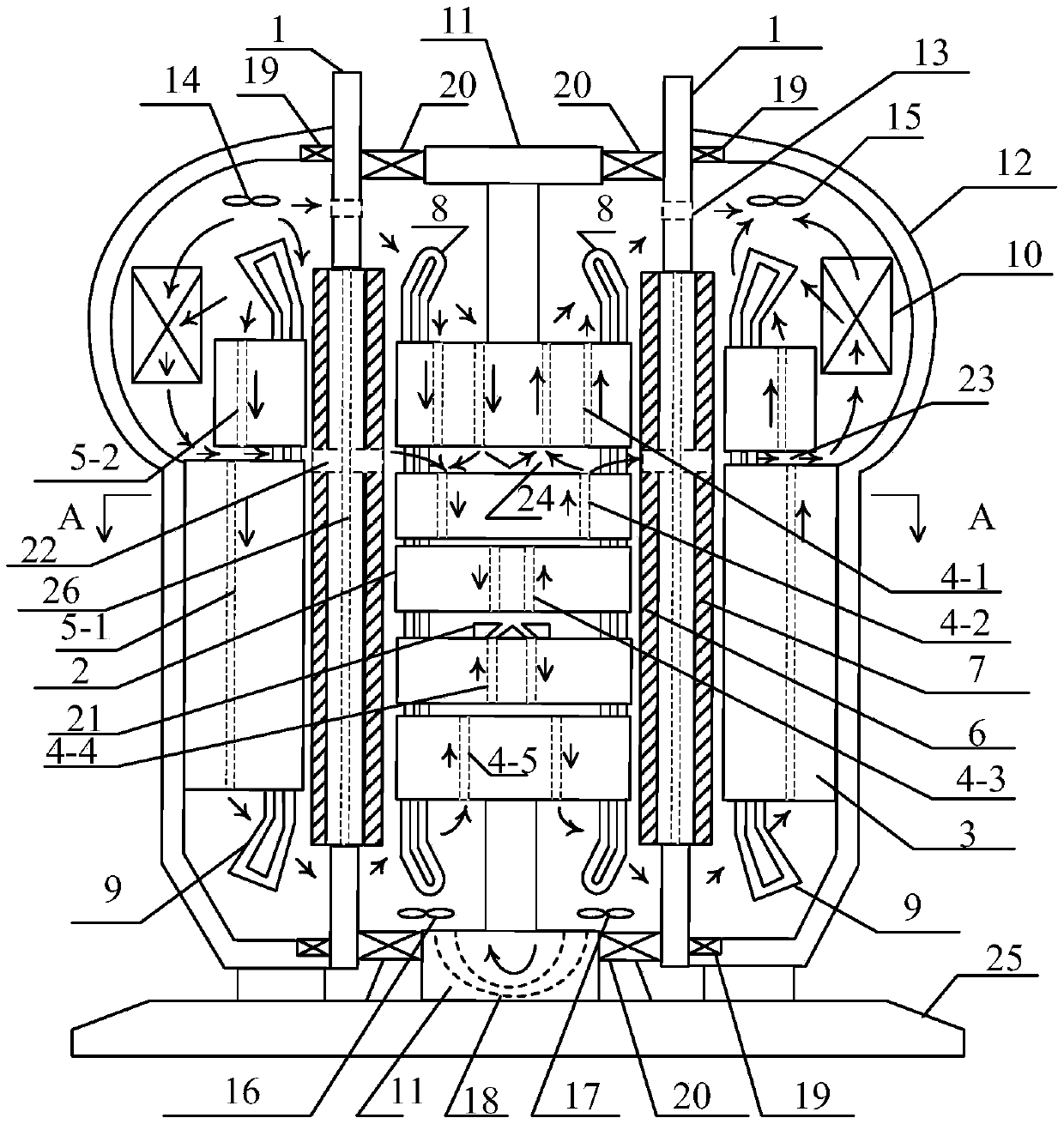

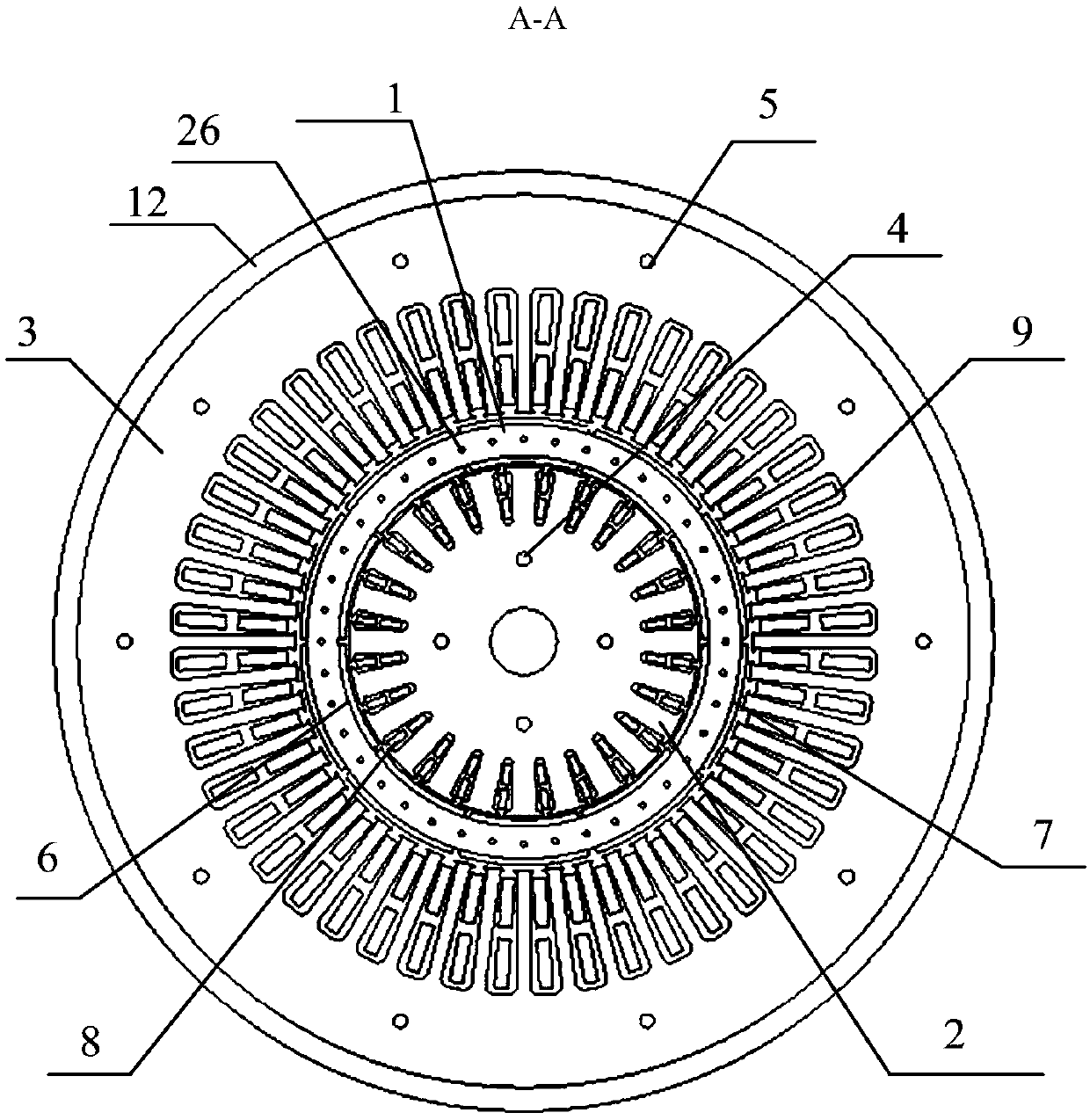

[0029] Example: see Figure 1 to Figure 2 , the dual-stator and cylindrical permanent magnet rotor accelerator with closed cycle multi-channel countercurrent cooling in this embodiment includes a cylindrical rotor 1, an inner stator core 2, an outer stator core 3, a permanent magnet 6 in the inner layer of the rotor, and an outer layer of the rotor Permanent magnet 7, inner stator winding 8, outer stator winding 9, inner stator casing 11, outer stator casing 12, cylindrical rotor outer ring bearing 19, cylindrical rotor inner ring bearing 20;

[0030]The cylindrical rotor 1 is arranged between the inner stator core 2 and the outer stator core 3, and the cylindrical rotor 1 is connected to the outer stator casing 12 and the outer stator casing 12 through the cylindrical rotor outer ring bearing 19 and the cylindrical rotor inner ring bearing 20 respectively. The inner stator casing 11 is connected, and the inner layer and the outer layer of the cylindrical rotor 1 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com