Voltage-adjustable safe battery pack

A battery pack and adjustable technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of battery pack burnout, battery pack damage, poor battery pack safety and economy, and achieve reliable and practical voltage output Wide range and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

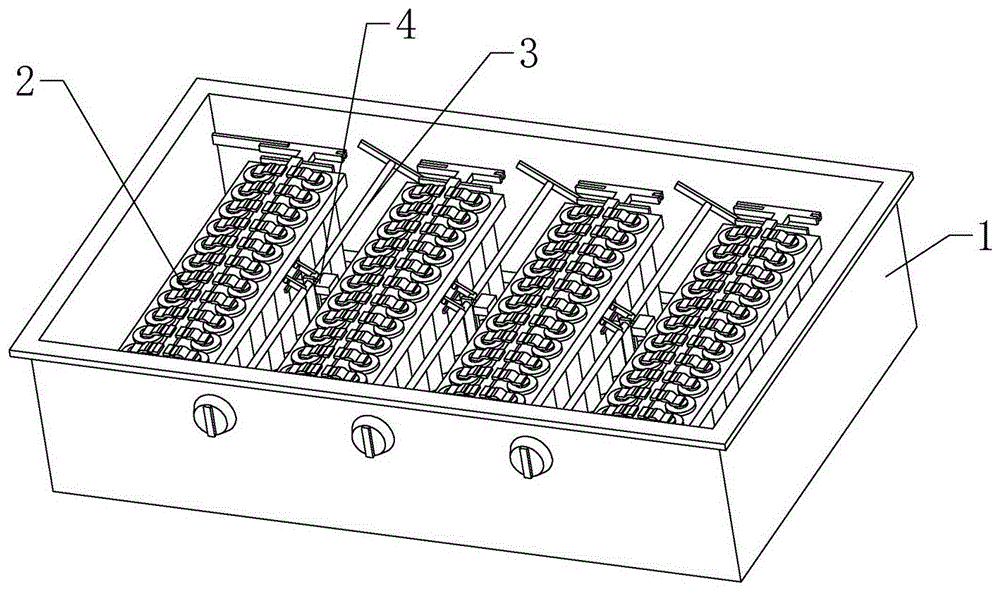

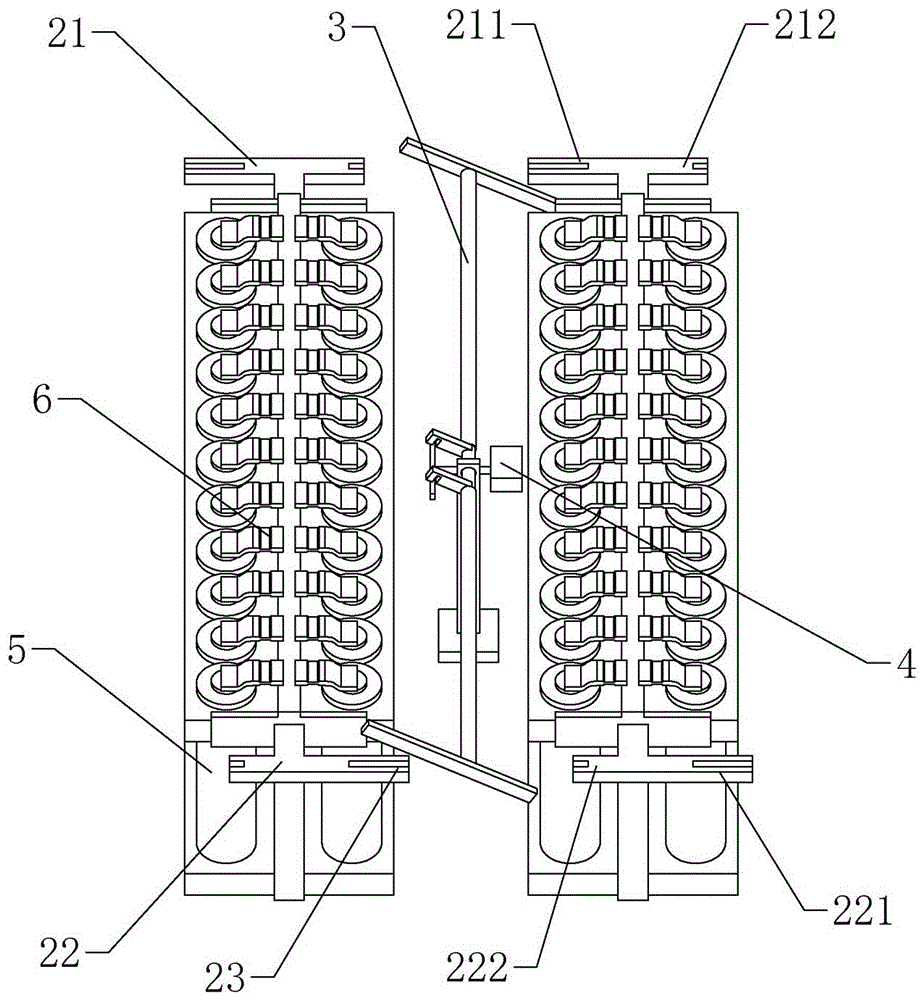

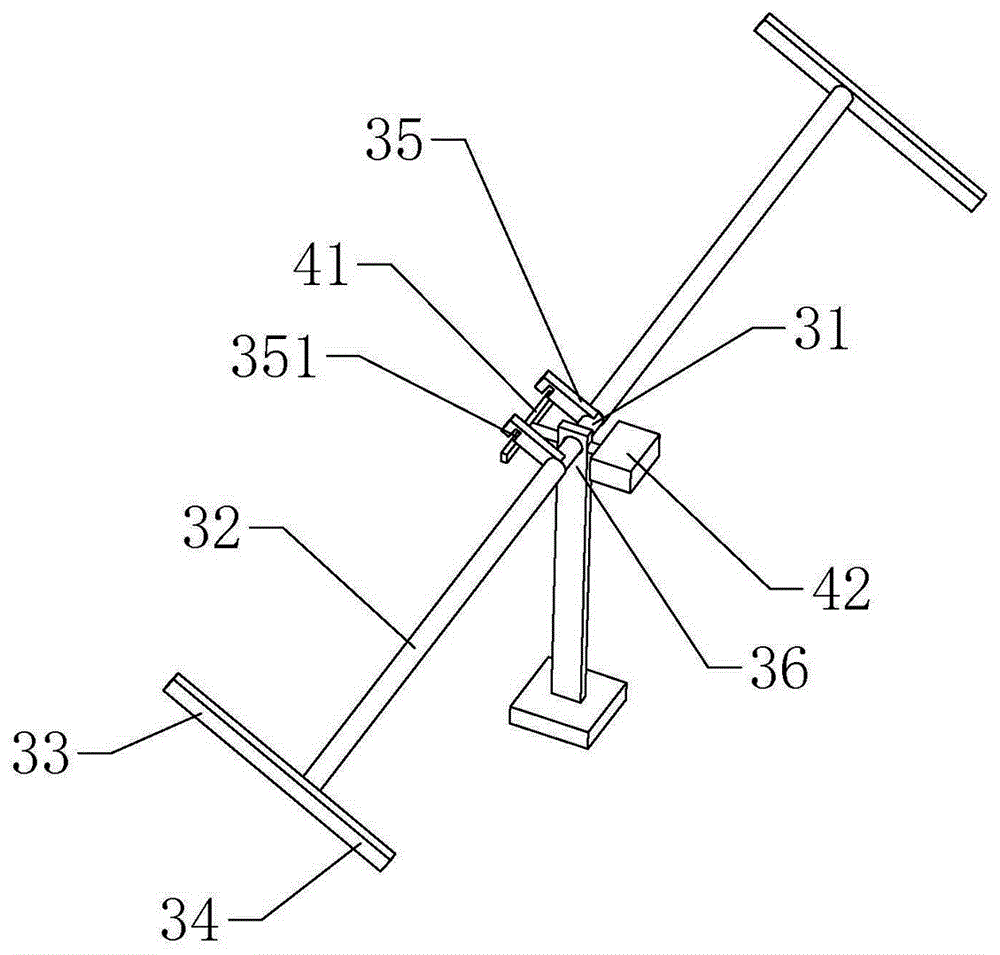

[0035] according to Figure 1 to Figure 6 As shown, a safety battery pack with adjustable voltage includes a battery pack case 1 and a battery pack 2 inside the battery pack case 1, the number of battery packs 2 in the battery pack case 1 is more than two groups, and the battery pack 2 includes, The first terminal post 21 and the second terminal post 22 arranged at both ends of the battery pack 2, the battery cell 5 and the safety nickel belt 6 used to connect the battery cell 5 are arranged between adjacent battery packs 2 to adjust the battery. An adapter rod 3 and an adapter block 4 in the connection mode of the battery pack 2, and a connection terminal 11 connected to the battery pack 2 is arranged inside the battery pack case 1 .

[0036] The first terminal 21 includes a first long contact 211 and a first short contact 212; the second terminal 22 includes a second long contact 221 and a second short contact 222, and the first long contact 211 is set away from the transfer...

Embodiment 2

[0041] The difference from the above-mentioned embodiment 1 is that, according to Figure 7 As shown, the connecting hole 6311 is provided in the connecting area 631 of the main belt, and the positioning hole 611 is provided on the main belt body 61. The fastener 64, the connecting hole 6311 and the positioning hole are passed between the connecting area 631 and the main belt body 61. 611 is fixed, and the strap connection area 32 is welded and fixed to the battery cell 5. This structure allows the battery cell to be disassembled separately. When a single battery cell is damaged, it is convenient to replace the battery cell.

Embodiment 3

[0043] The difference from the above-mentioned embodiment 1 or 2 is that there are several through holes in the protection area 33 , the cross-sectional area of the protection area is reduced by setting the through holes, and the porous structure is beneficial to the fracture of the protection area 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com