Single bearing structured heavy-duty locomotive traction motor

A technology for heavy-duty locomotives and traction motors, applied in electromechanical devices, electrical components, electric components, etc., can solve problems such as unreasonable connection structures and inability to replace bearings online, reduce maintenance time and cost, improve punctuality and Utilization rate, effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

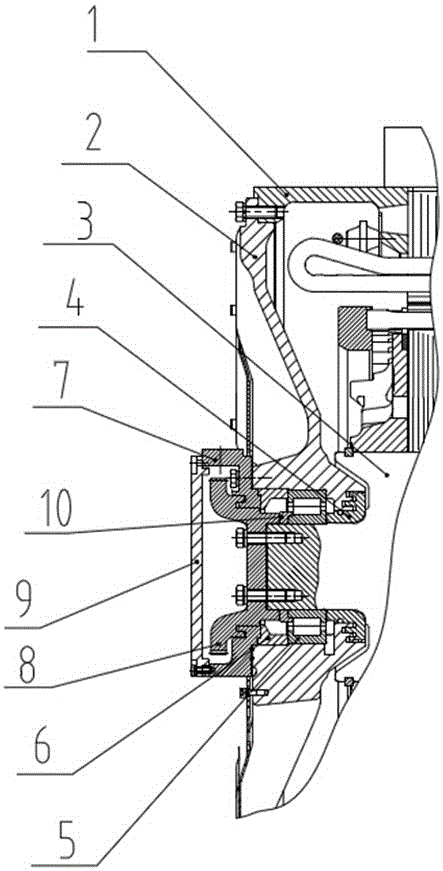

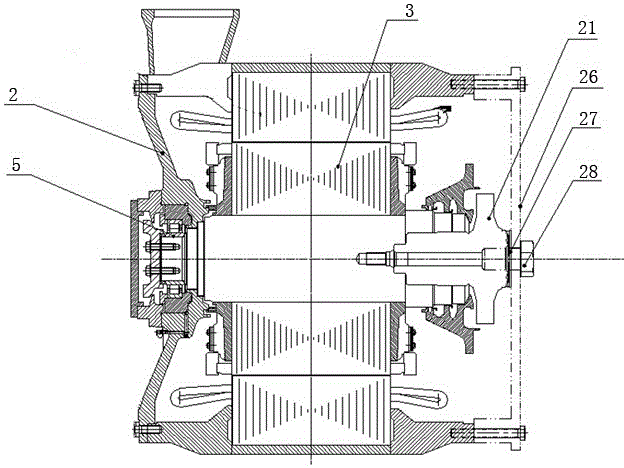

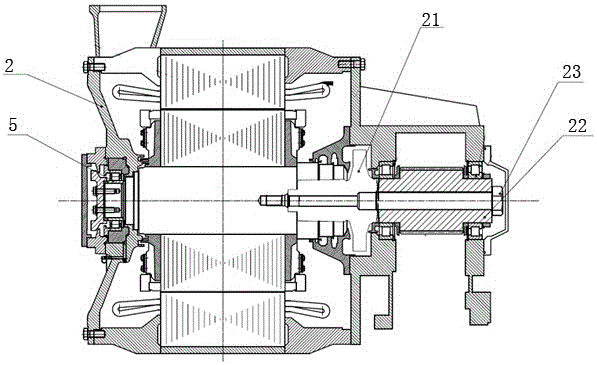

[0019] The traction motor of a heavy-duty locomotive with a single bearing structure includes a frame 1, a non-transmission end cover 2, a rotor 3, a bearing 5, a bearing retainer ring 6, and a bearing corner ring 10; the transmission end of the rotor shaft is connected with a coupling 21, The coupling is in the shape of a column, and a threaded through hole is opened along the axis of the cylindrical coupling. One end of the coupling is provided with meshing teeth 21-1; the transmission end of the rotor shaft is provided with a fixing hole. The axis coincides with the axis of the rotor shaft; one end of the non-meshing tooth of the coupling is inserted into the fixing hole with interference fit. In specific implementation, the traction motor further includes a fixing tool 26, a rubber pad 27, and a fixing tool bolt 28 fixedly connected to the base 1. Such as figure 2 As shown, after the final assembly is completed, a rubber pad 27 is placed between the coupling and the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com