Laser marking and bleaching device and machining method thereof

A laser marking and laser technology, applied in the fields of bleaching equipment and laser marking, can solve the problems of real-time parameter feedback to the controller, lack of real-time detection, and reduce marking work efficiency, so as to improve the marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

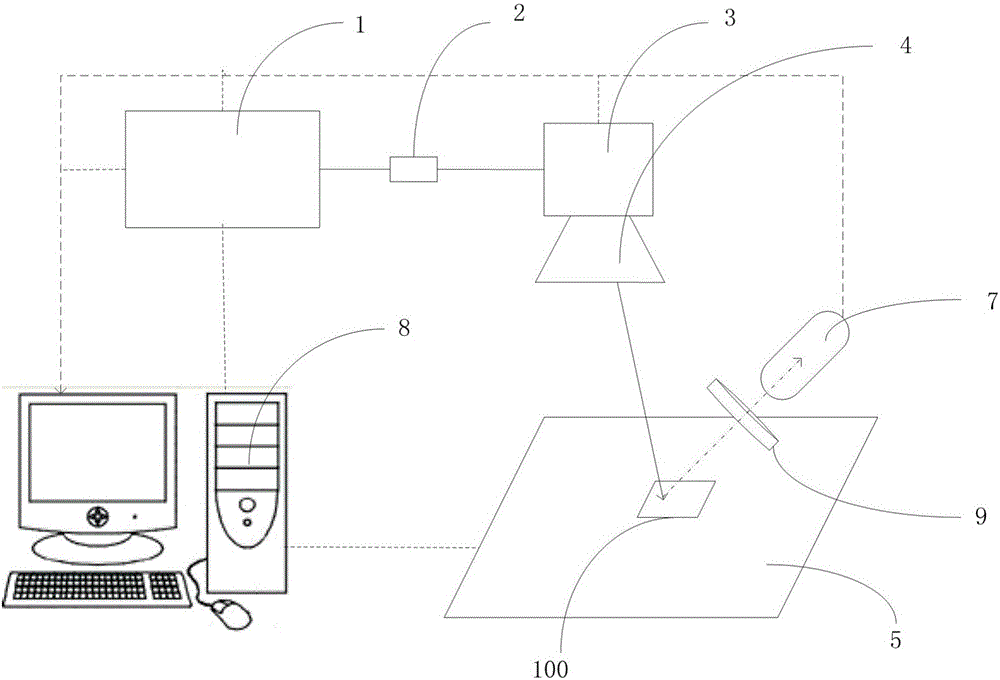

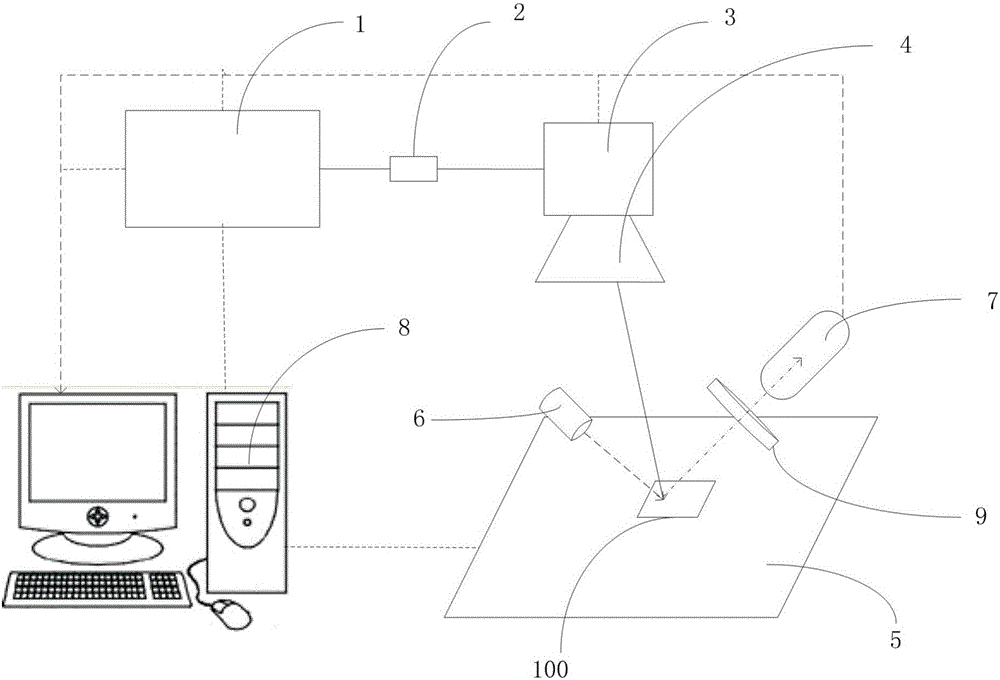

[0027] The invention discloses a feedback type laser marking and bleaching machine, such as figure 1 As shown, it includes:

[0028] A laser 1 for emitting laser light;

[0029] A beam expander 2, located behind the laser 1, is used to set the diameter of the laser beam;

[0030] A oscillating mirror 3, located behind the beam expander 2, is used to control the deflection of the laser beam;

[0031] A lens 4, located behind the vibrating mirror 3, is used to penetrate the laser beam;

[0032] A mobile platform 5, facing the light-emitting side of the lens 4, for placing the workpiece 100;

[0033] A power detection device 7, which is electrically connected to the industrial computer 8, is used to measure the reflected light power at a given point in the marking and bleaching area on the workpiece 100; the power detected by the power detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com