Manufacture method for production of dextrin by microwave method

A manufacturing method, the technology of the microwave method, applied in the field of dextrin manufacturing, can solve the problems of increased production cost, unstable product quality, and limited volume of the blender, and achieve energy saving, precise control of drying temperature, and stable product quality. Effect

Inactive Publication Date: 2016-11-02

江苏昕宇药业有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the existing dry method of producing dextrin, due to the limitation of the volume of the reaction pot, this will cause a certain difference in the degree of dextrinization between the pots, so that the unit batch is too small (such as using a large volume Blender, on the one hand, the volume of the blender is limited, and on the other hand, it will increase the production cost) The quality of the product is not stable enough

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

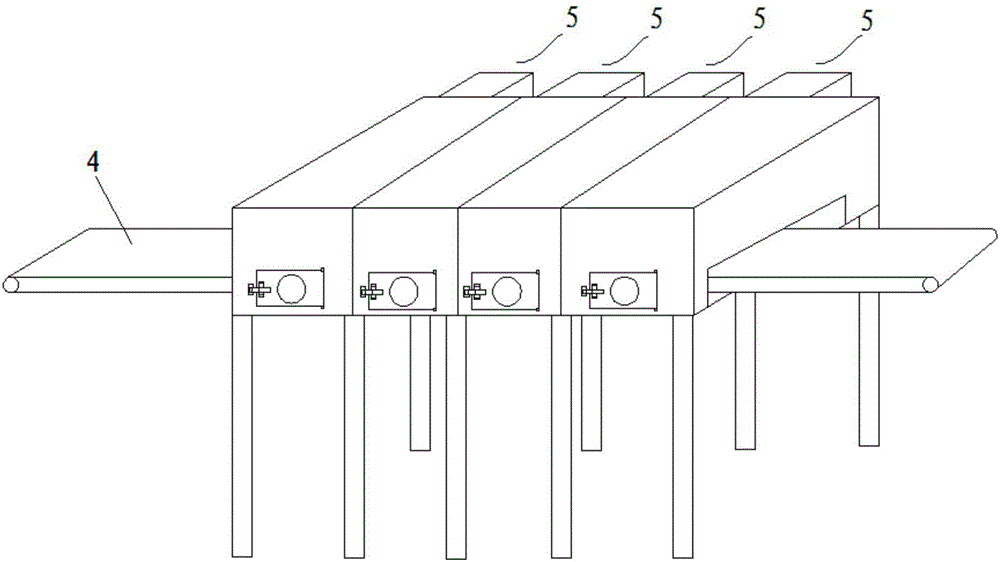

[0041] Example 1, the material is spread on the conveyor belt with a thickness of 0.025 meters, and the conveyor belt speed is set at 1.5 meters / minute.

Embodiment 2

[0042] Example 2, the material is laid on the conveyor belt with a thickness of 0.03 meters, and the conveyor belt speed is set to 1.0 m / min.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

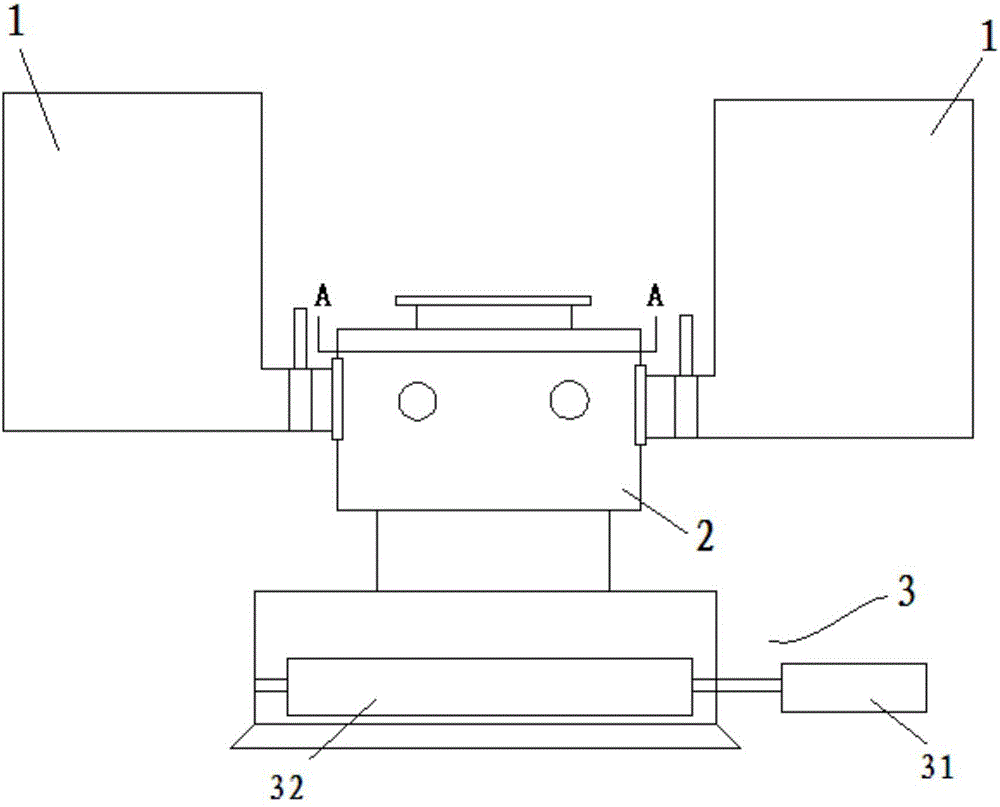

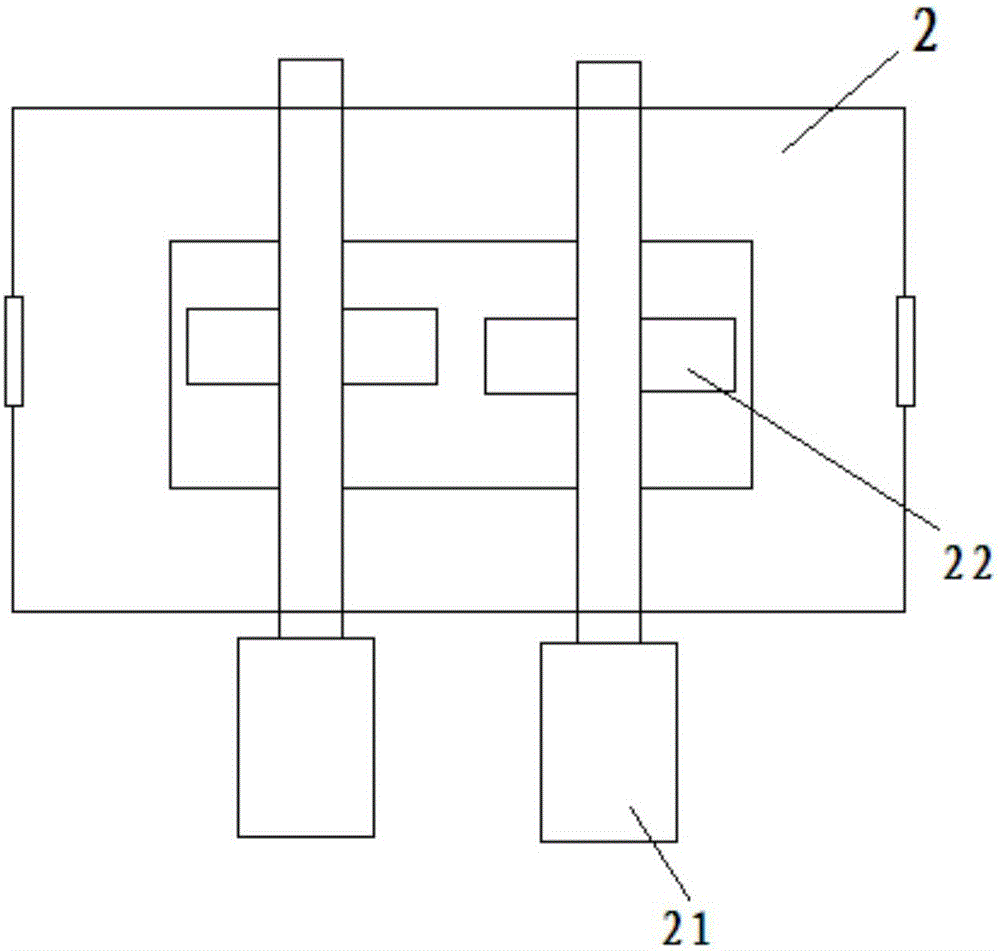

The invention discloses a manufacture method for production of dextrin by a microwave method. the manufacture method comprises the following steps: Step 1, selecting corn starch as a material; Step 2, spraying the material into a nitric acid solution and uniformly stirring; Step 3, digging equal quantity of the material in a material barrel into a spreading device by the utilization of an automatic feeding system, and spreading the material onto a conveyor belt by the spreading device; Step 4, setting operation speed of the conveyor belt according to corresponding material thickness, sending the material into a multistage microwave drying oven, heating, drying, dextrinizing and sterilizing; and successively raising heating temperature of each stage in the multistage microwave drying oven; Step 5, sending the material into an agitator and detaching; Step 6, screening by a vibrating screen; Step 7, detecting dextrin; and Step 8, carrying out measurement packing according to standards. Due to line production of the whole production line, degree of automation is high. Meanwhile, temperature and moisture of the material can be monitored at real time, thus guaranteeing stability of product quality.

Description

technical field [0001] The invention relates to a method for producing dextrin by a microwave method, and belongs to the technical field of dextrin production. Background technique [0002] At present, the existing dry method of producing dextrin, due to the limitation of the volume of the reaction pot, this will cause a certain difference in the degree of dextrinization between the pots, so that the unit batch is too small (such as using a large volume Blender, on the one hand, the volume of the blender is limited, and on the other hand, the production cost is increased) to form a product whose quality is not stable enough. This method will also bring about uneven heating in the pot and uncontrollable dust, and at the same time greatly reduce the risk of dust explosion. Contents of the invention [0003] Objective: In order to overcome the deficiencies in the prior art, the present invention provides a method for producing dextrin by microwave method. [0004] Technical...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08B30/18C08B30/16

CPCC08B30/18C08B30/16

Inventor 王俭

Owner 江苏昕宇药业有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com