Immersed tube tunnel dry dock bottom floating layer structure with ultra-filtration drainage grooves

A technology of immersed tube tunnel and floating layer, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., and can solve problems such as easy damage of plywood and gravel layers, poor drainage effect of drainage channels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

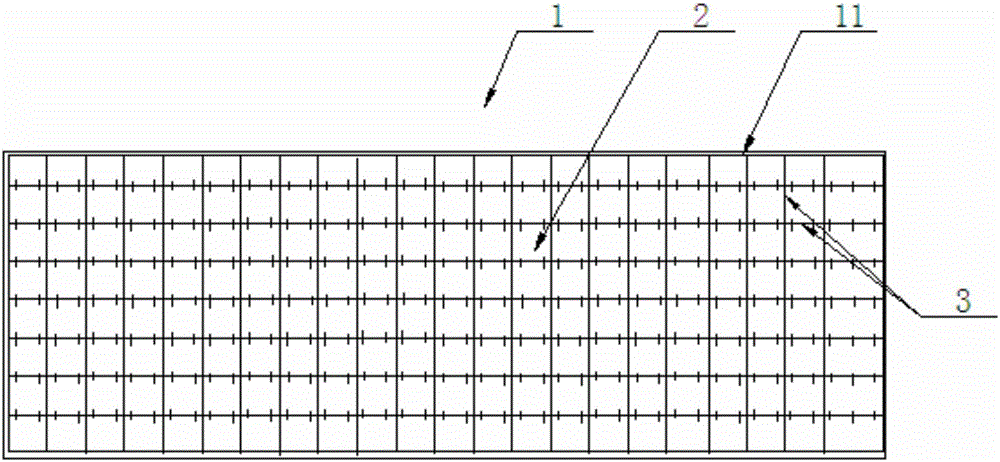

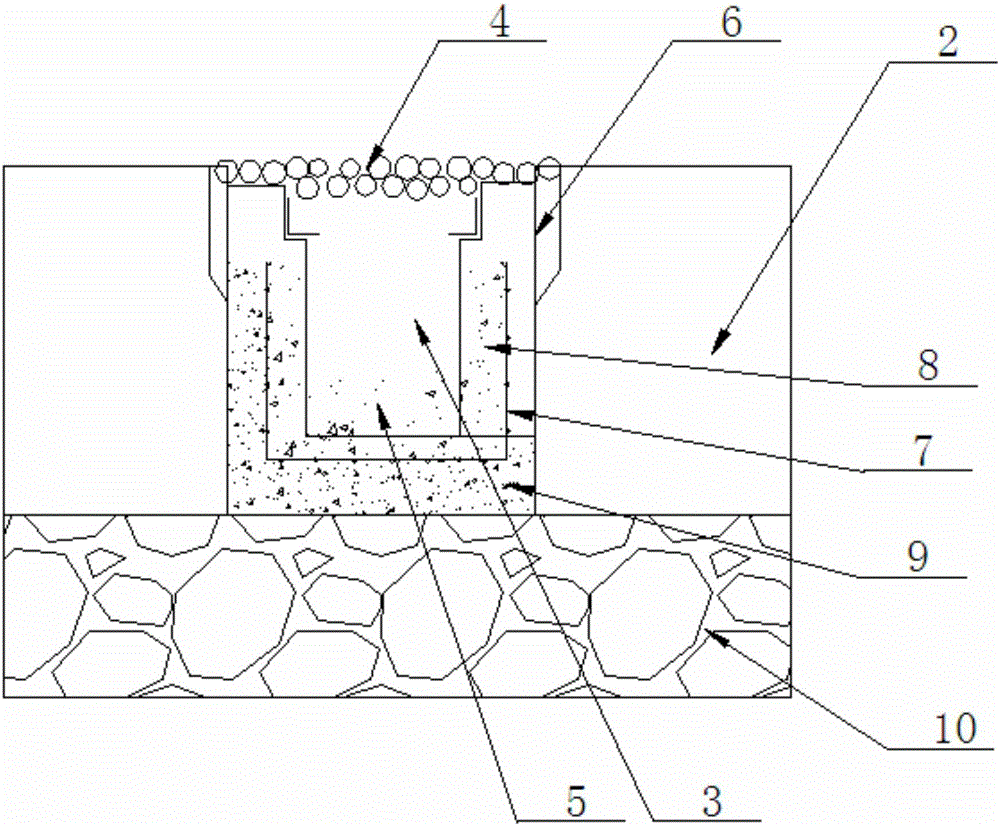

[0015] see as figure 1 —— figure 2 As shown, the present specific embodiment adopts the following technical scheme: it includes floating layer structure 1, floating layer 2, drainage tank 3, pebble layer 4, first concrete layer 5, formwork 6, Single-layer two-way steel mesh 7, second concrete layer 8, third concrete layer 9, gravel layer 10; the surface of the floating layer structure 1 at the bottom of the dry dock of the immersed tube tunnel is a floating layer 2, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com