Method for determining region turning point of titanium alloy fatigue crack growth rate curve Paris

A technology of fatigue crack growth and crack growth, which is applied in the field of fatigue crack growth behavior analysis, can solve the problems of large twists and turns, inconsistencies, and deviations of test data curves, and achieve the effects of sufficient scientific basis, high accuracy, and complete technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

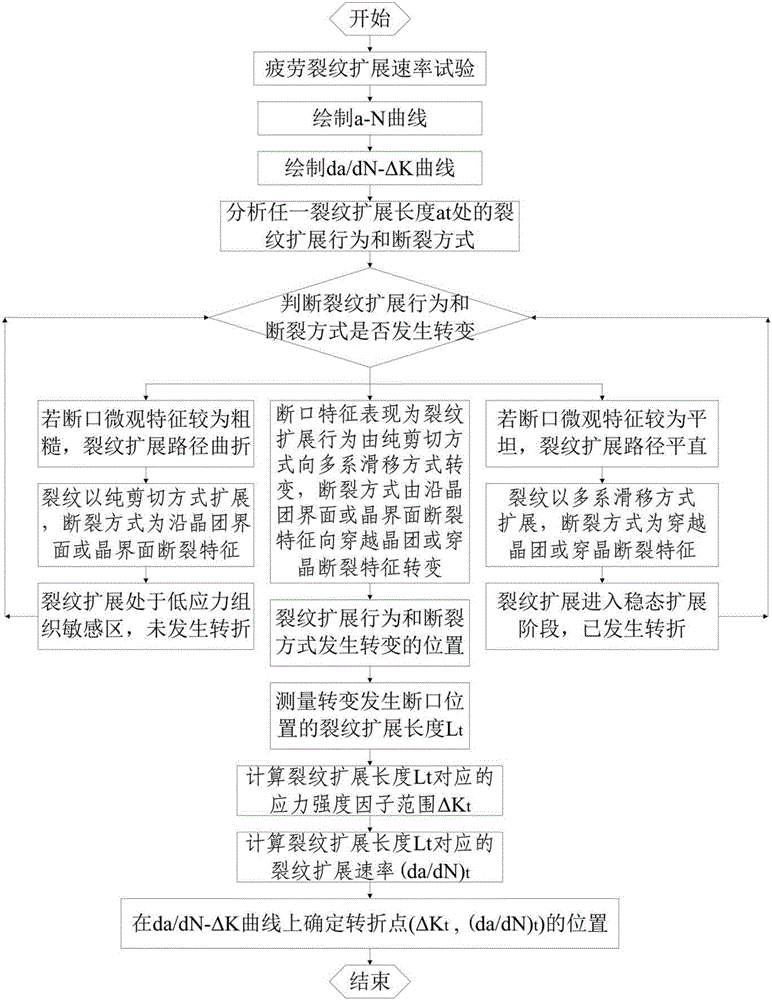

Method used

Image

Examples

Embodiment

[0045] Step 1. Get ready to start. In this example, the medium-strength, high-toughness, and high damage-tolerant TC4-DT titanium alloy is used as the object. After conventional two-phase zone forging and quasi-β heat treatment, the obtained microstructure is a typical lamellar structure. The composition and mechanical properties of the material The properties are shown in Table 1 and Table 2.

[0046] Table 1 Material Composition

[0047]

[0048] Table 2 Mechanical properties

[0049]

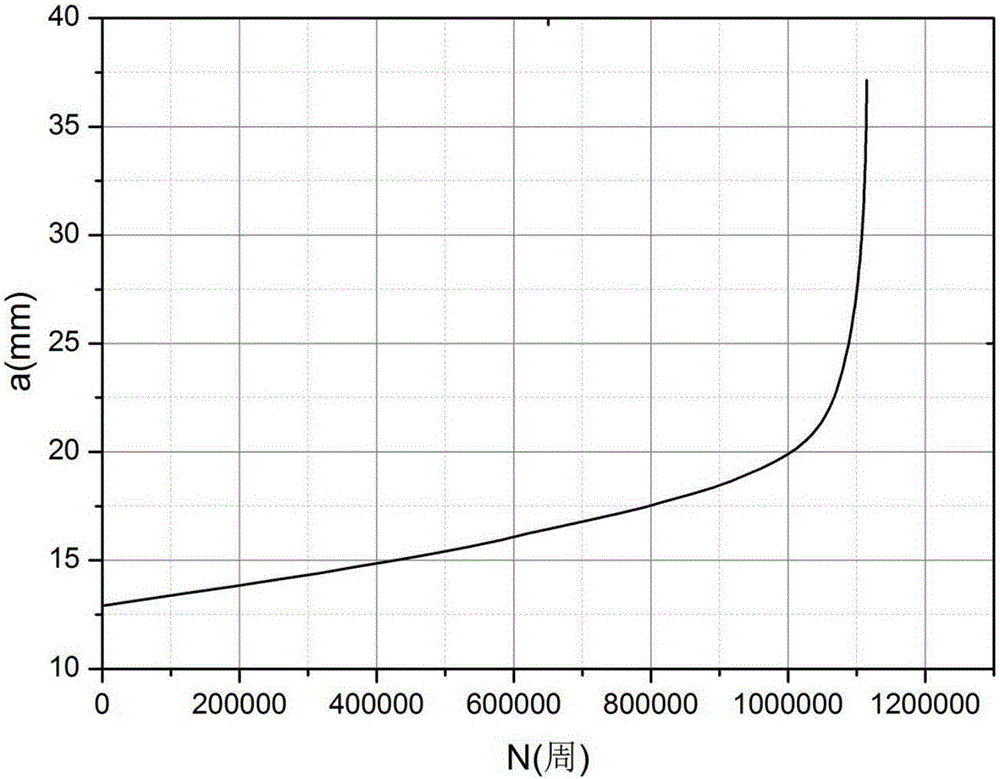

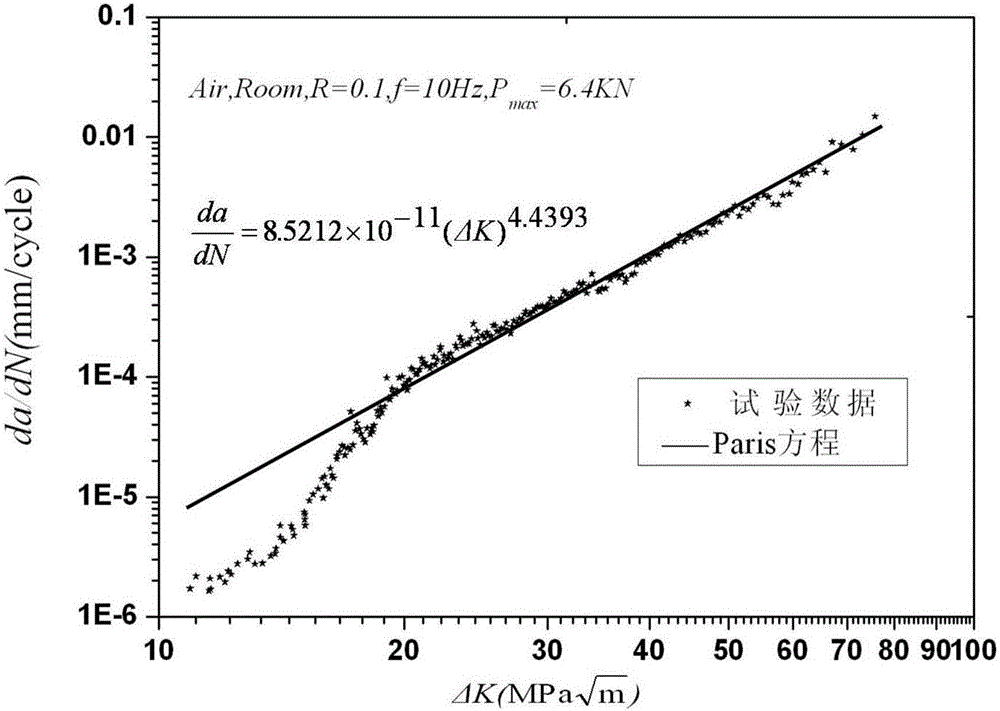

[0050] Step 2: Carry out fatigue crack growth rate test. The fatigue crack growth rate test is carried out according to the "Metallic Materials Fatigue Crack Growth Rate Test Method" (GB / T 6398-2000), the test environment is room temperature, air, the test frequency f=10Hz, and the maximum load P max =6.4KN, stress ratio R=0.1. Record the i-th load cycle number N during the test i and N i The corresponding crack growth length a i , to obtain all experimental data points (N i ,a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com