Electronic component joint

A technology for electronic components and bonding heads, which is used in the assembly of printed circuits with electrical components, metallurgical bonding, etc., can solve the problems of equipment operation performance damage, solder bump collapse, productivity deterioration, etc., to reduce thermal expansion fluctuations and improve productivity. , the effect of suppressing bump collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Embodiments according to the present invention will be described in detail below with reference to the drawings.

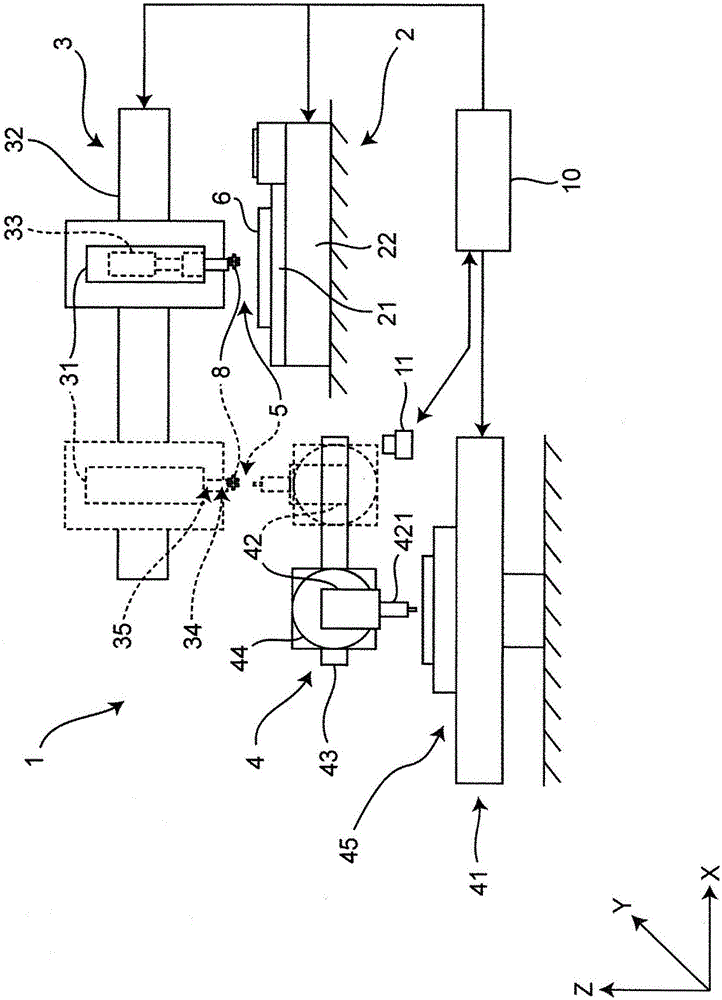

[0086] First, the main reference figure 1 The structure of the electronic component mounting apparatus 1 provided with the electronic component bonding head in this embodiment is demonstrated.

[0087] in, figure 1 It is a schematic front view of the electronic component mounting apparatus 1 provided with the electronic component bonding head in embodiment concerning this invention.

[0088] The electronic component mounting apparatus 1 is a so-called flip-chip mounting apparatus that simultaneously mounts and bonds electronic components to fine electronic components used in systems such as LSI (Large Scale Integration) and a circuit board 6 such as a printed circuit board as an object. .

[0089] The electronic component mounting apparatus 1 includes a substrate holding unit 2 , a component mounting unit 3 having a bonding head 5 , a component supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com