Process for loading hydrogen-absorbing alloy

A technology of hydrogen storage alloy and filling method, which is applied in the direction of chemical instruments and methods, hydrogen, non-metallic elements, etc., can solve problems such as filling difficult alloys, achieve pressure loss suppression, shorten time, and reduce changes in hydrogen release performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] Examples of the present invention will be described below while comparing with comparative examples.

[0109]

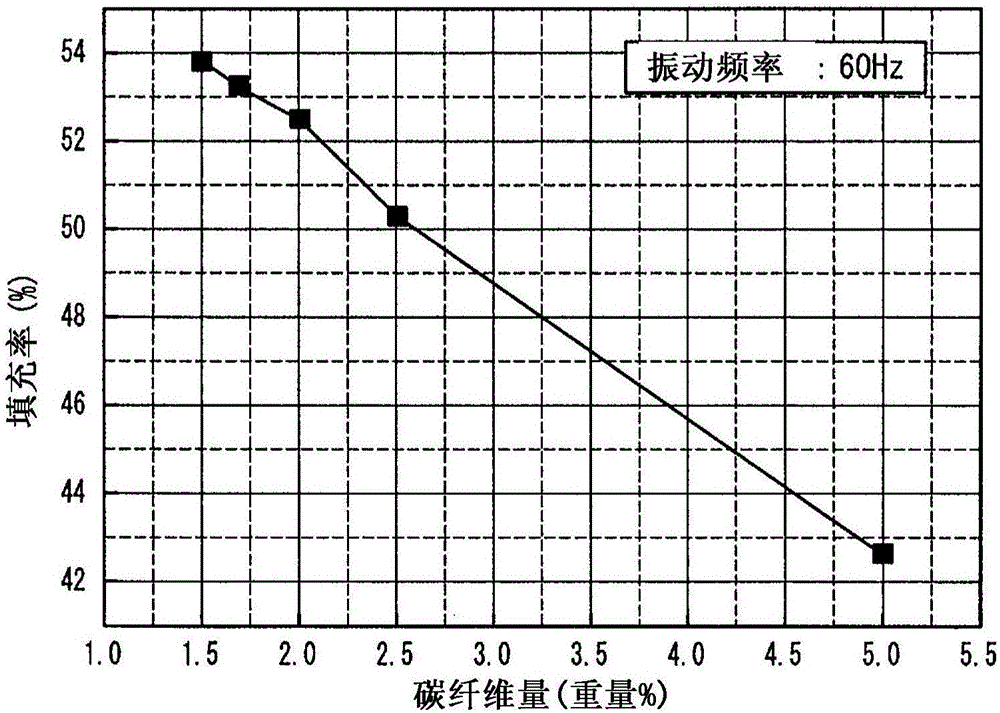

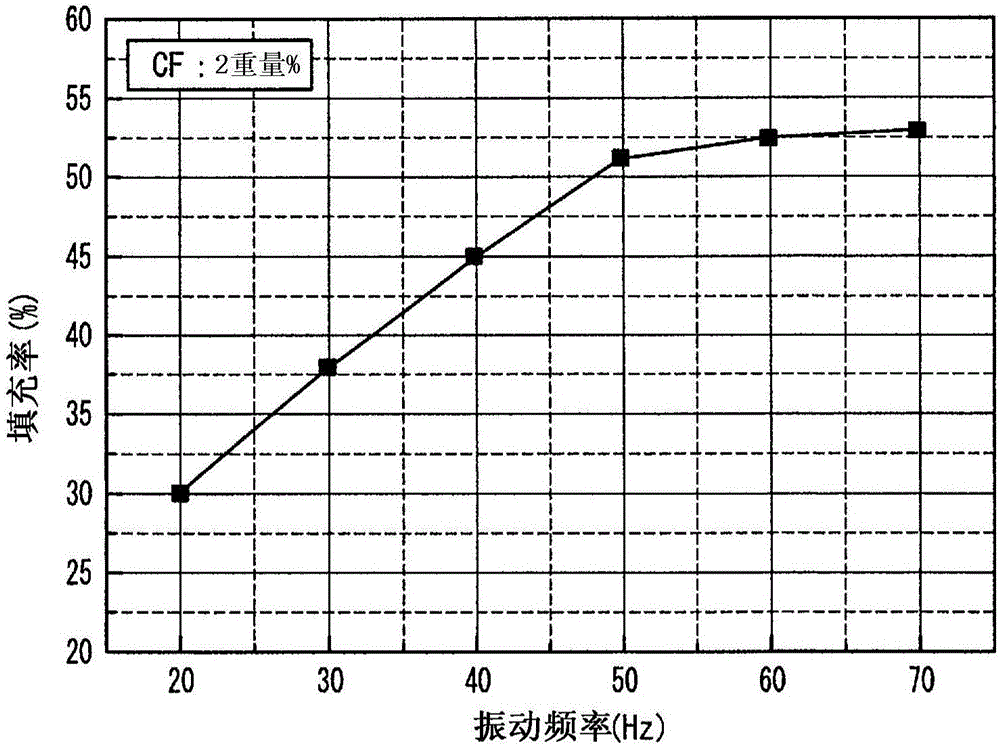

[0110] An aluminum cylinder having an inner volume of 800 mL and an opening inner diameter of 14 mm was prepared. In addition, prepare AB with an average particle size of about 700 μm 5 Alloy-like, 3.5% by mass of a gel-like silicone resin having a viscosity of 1000 mPa·s and a 1 / 4 consistency at 25°C of 85, and 2% by mass of a diameter of 10 μm, a length of 6 mm, and an aspect ratio of 600 needle-shaped carbon fibers, and they are mixed and stirred to obtain a resin composite material.

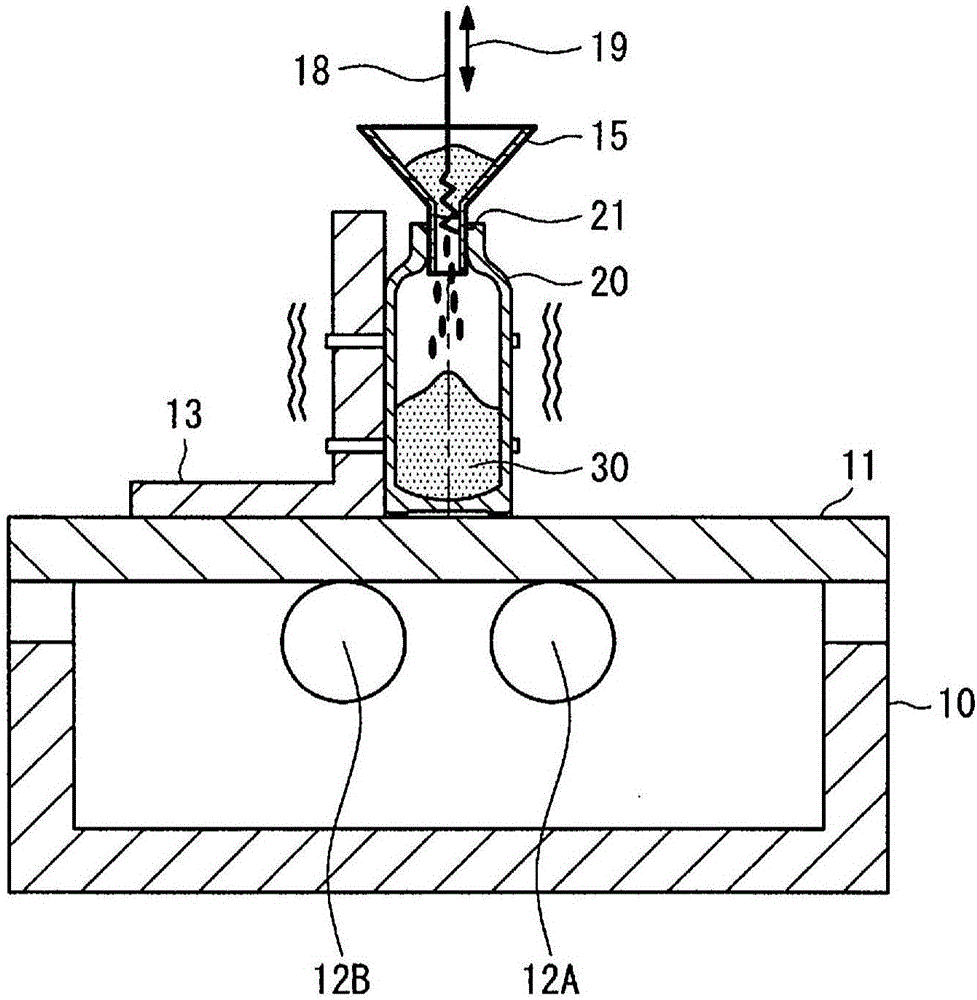

[0111] use figure 1 The device shown in , with the target filling rate set at 52%, filled the resin composite material into the container while applying vibration at a vibration frequency of 50 Hz, a displacement of 1.6 mm, and a vibration time of 5 minutes middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com