Novel grain storage four-in-one technology and two-way ventilation, circulation, air conditioning and ozone grain storage system

A new and technical technology, applied in the field of granary ventilation and circulation system, can solve the problems of grain aging and mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

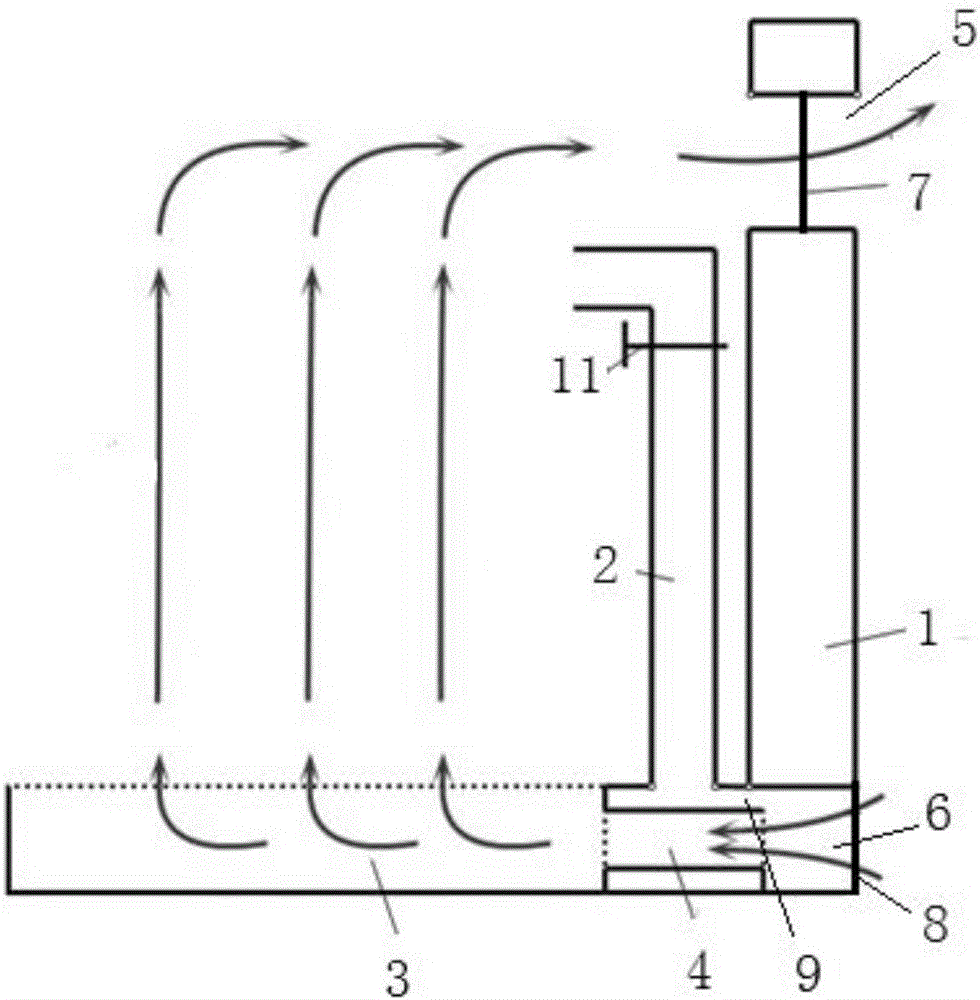

[0019] Specific implementation mode one: combine figure 1 Describe this embodiment, the new grain storage four-in-one technology of this embodiment and two-way ventilation, circulation, air conditioning, ozone grain storage system press-in type to reduce grain temperature, use this mode of ventilation, first need to open the granary window 7 and the ventilation cage cover Plate 8, close the airtight valve 11, start the two-way mixed flow fan 4, realize press-in ventilation, the external air passes through the two-way mixed flow fan 4, passes through the granary ventilation cage 3, passes through the grain pile upwards, and finally discharges into the atmosphere through the granary window 7 , this kind of ventilation mode, the gas touches the bottom of the grain pile first, the grain at the bottom layer cools down first, and the grain at the upper layer cools down and gets water last. high.

specific Embodiment approach 2

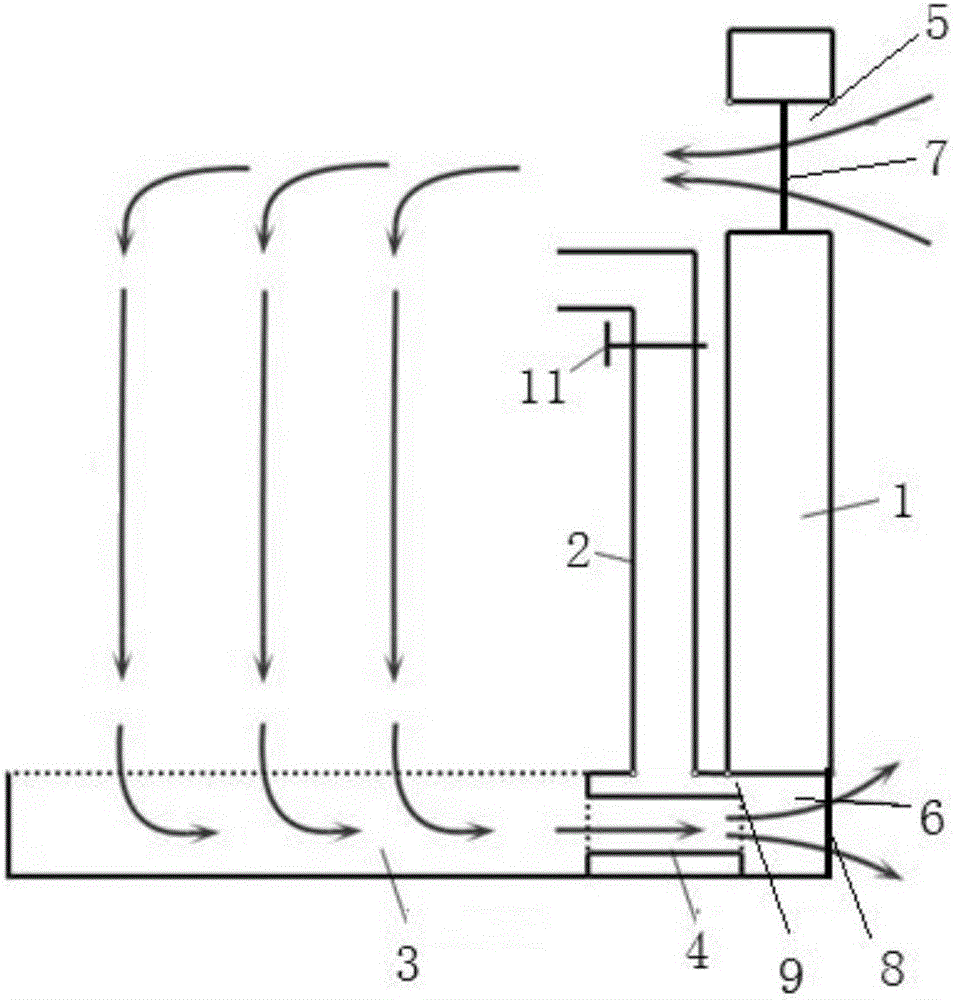

[0020] Specific implementation mode two: combination figure 2 Illustrate this embodiment, this embodiment adopts the suction-type ventilation mode for lowering the grain temperature, first open the granary window 7 and the ventilation cage cover 8, close the airtight valve 11, start the two-way mixed-flow fan 4 suction-type ventilation, the outside atmosphere passes through the window, Pass through the grain pile, pass through the ventilation cage 3 of the granary, pass through the two-way mixed flow fan 4, and finally discharge out of the warehouse through the second vent 6; in this ventilation mode, the gas first touches the upper layer of the grain pile, and the grain on the upper layer is first cooled and dehydrated. The grain at the bottom finally cools down and rains. After long-term ventilation, the grain moisture in the upper layer is low, and the grain moisture in the bottom is high.

specific Embodiment approach 3

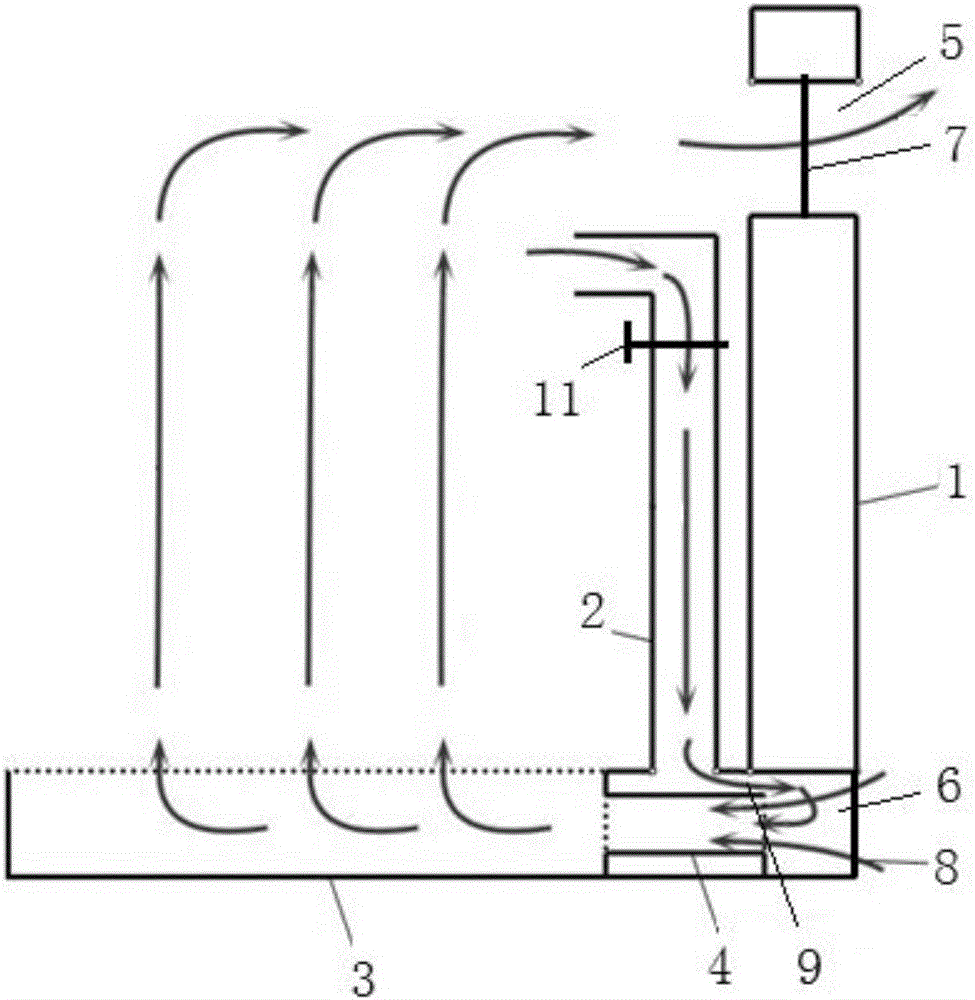

[0021] Specific implementation mode three: combination image 3 To illustrate this embodiment, the press-in recyclable part of the "tail gas" ventilation mode for lowering the grain temperature is adopted. Using this mode for ventilation, the granary window 7 and the ventilation cage cover 8 are opened, the airtight valve 11 is closed, and the two-way mixed flow fan 4 is started to press in The external air passes through the two-way mixed-flow fan 4, passes through the granary ventilation cage 3, and passes through the grain pile upwards. Part of the gas is discharged into the atmosphere through the granary window 7, and part of the discharged air enters the negative side of the two-way mixed-flow fan through the ventilation circulation pipe 2. The compressor end (that is, the ventilation reserved opening 9) re-enters the grain pile. This ventilation mode can slightly increase the temperature and humidity of the ventilation air, reducing the moisture loss in the ventilation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com