Making process of agaricus bitorquis cake

A production process, the technology of big fat mushrooms, applied in the field of cake and its production process, can solve the problems of lack of anti-aging, anti-tumor, anti-virus, and lack of anti-hypoxia, etc., to improve immunity, anti-inflammatory immunity, solve Effects of hypoxia problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the manufacturing process of the big fat mushroom cake, each raw material is as follows: 25 grams of flour, 18 grams of white granulated sugar, 3.8 grams of Qaidam big fat mushroom dried mushroom powder, 28 grams of eggs, Angelica high active yeast powder 0.2 g.

[0020] The manufacturing process of this cake is carried out as follows:

[0021] (1) The large fat mushrooms are crushed and sieved to make dried mushroom powder;

[0022] (2) Beat eggs to make egg liquid, add white granulated sugar and beat well to obtain egg liquid; then add it to low-gluten flour, stir evenly and let stand for fermentation;

[0023] (3) Activate the Angel High Active Dry Yeast Yeast Powder with warm water and mix it with the flour, then add the egg mixture and stir evenly;

[0024] (4) Add the dried big fat mushroom powder, and then mix the paste evenly;

[0025] (5) Immediately pour the mold after mixing the paste evenly, and apply a layer of vegetable oil in the mold bef...

Embodiment 2

[0027] Embodiment 2, the manufacturing process of the big fat mushroom cake, the raw materials are as follows: 23 grams of flour, 16 grams of white granulated sugar, 3 grams of dried big fat mushroom powder, 20 grams of eggs, 0.1 gram of Angelica high active yeast powder ;

[0028] Cake making process is with embodiment 1.

Embodiment 3

[0029] Embodiment 3, the manufacturing process of the big fat mushroom cake, the preparation raw materials are as follows: 27 grams of flour, 20 grams of white sugar, 4.5 grams of big fat mushroom dried mushroom powder, 35 grams of eggs, 0.2 grams of Angelica high active yeast powder ;

[0030] Cake making process is with embodiment 1.

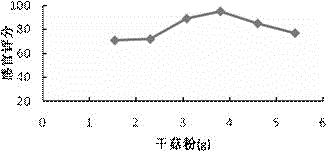

[0031] Table 1 The relationship between the content of dried mushroom powder and the quality of the cake

[0032]

[0033] Therefore, it is determined that the optimal range of dried mushroom powder content is 3-4.5 parts, and the range of cake sensory quality scores corresponding to this range is 90-95.3 points.

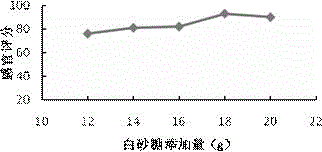

[0034] Table 2 The relationship between the amount of white sugar added and the quality of the cake

[0035]

[0036] Therefore, it is determined that the optimal range of white sugar addition is 16-20 parts, and the range of cake sensory quality scores corresponding to this range is 85-93 points.

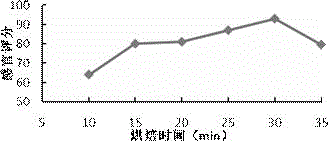

[0037] Table 3 Relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com