Shoe sole

A bottom surface and airbag technology, applied in the mechanical field, can solve the problems of not very satisfactory ventilation effect and inability to exchange directly, and achieve the effect of simple structure and strong air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The object of the present invention is to provide a shoe sole with simple structure and strong air permeability, which can directly discharge the turbid gas in the shoe to the outside air and keep the fresh air in the shoe.

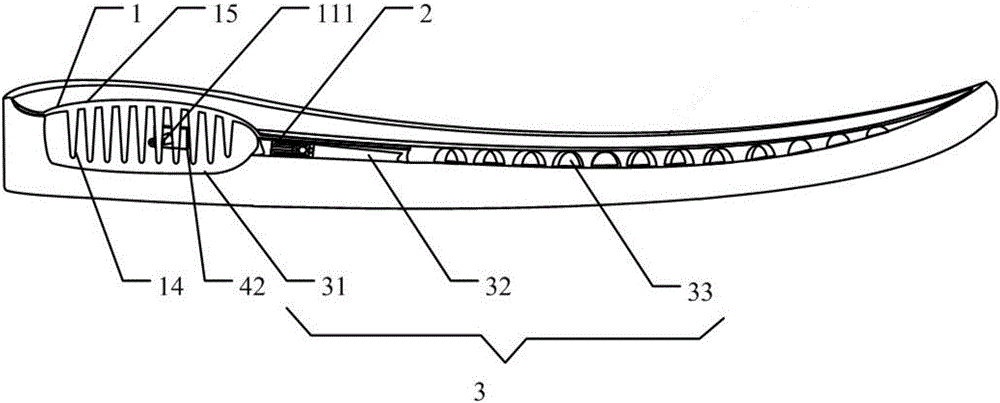

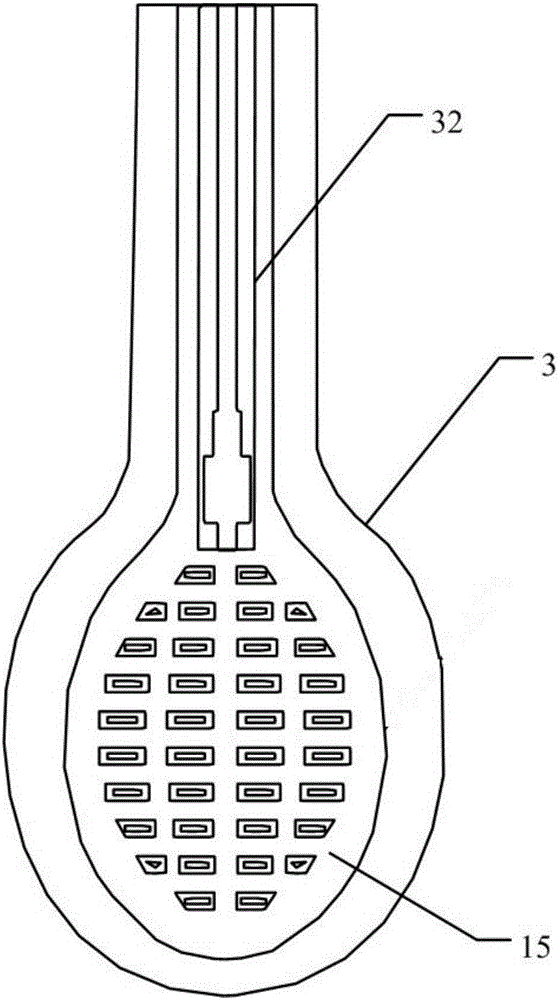

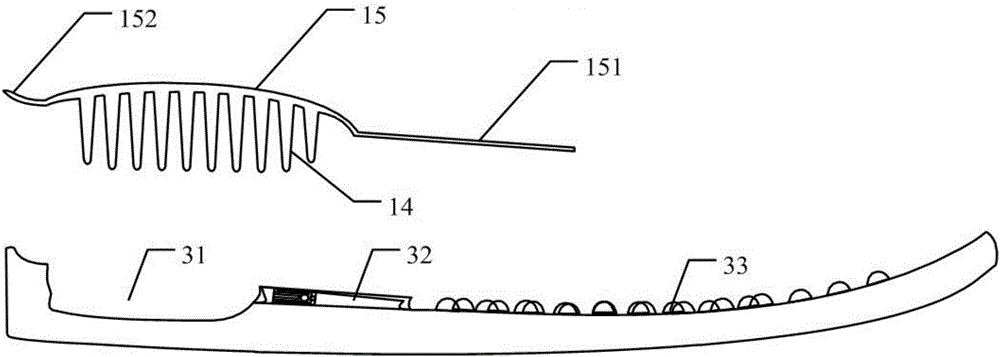

[0082] see below Figure 1-Figure 8 , a kind of sole embodiment among the present invention is described:

[0083] A shoe sole embodiment of the present invention includes: a gas exchange system and a shoe sole body 3; the shoe sole body 3 has an air bag socket 31 and an air guide cavity 32; the gas exchange system includes: an air bag formed by the air bag cover sheet 15 covering the air bag socket 31 Structure 1, the air guide cavity 32 and the elastic column array 14 fixedly connected to the bottom surface of the airbag cover 15; The upper wall of 32 overlaps; the space is reserved between the elastic column array 14 and the air bag socket 31; the gas exchange system also includes: the first one-way air valve 2 and the second one-way air valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com