Temperature responsive composite material, preparation method and application thereof

A composite material and responsive technology, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc., can solve the problems of low light utilization rate, application limitation, difficult recycling, etc., and achieve excellent electrical conductivity performance, good stability and activity controllability, and the effect of improving the photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

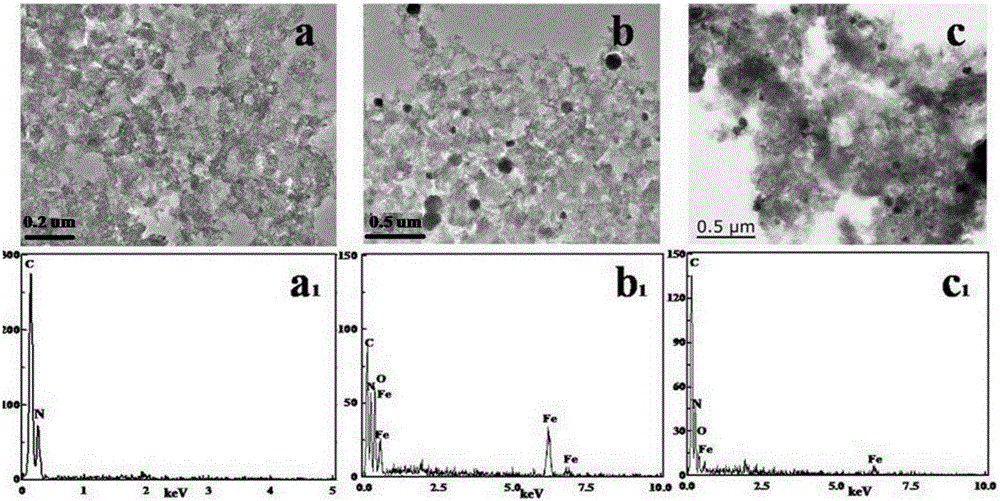

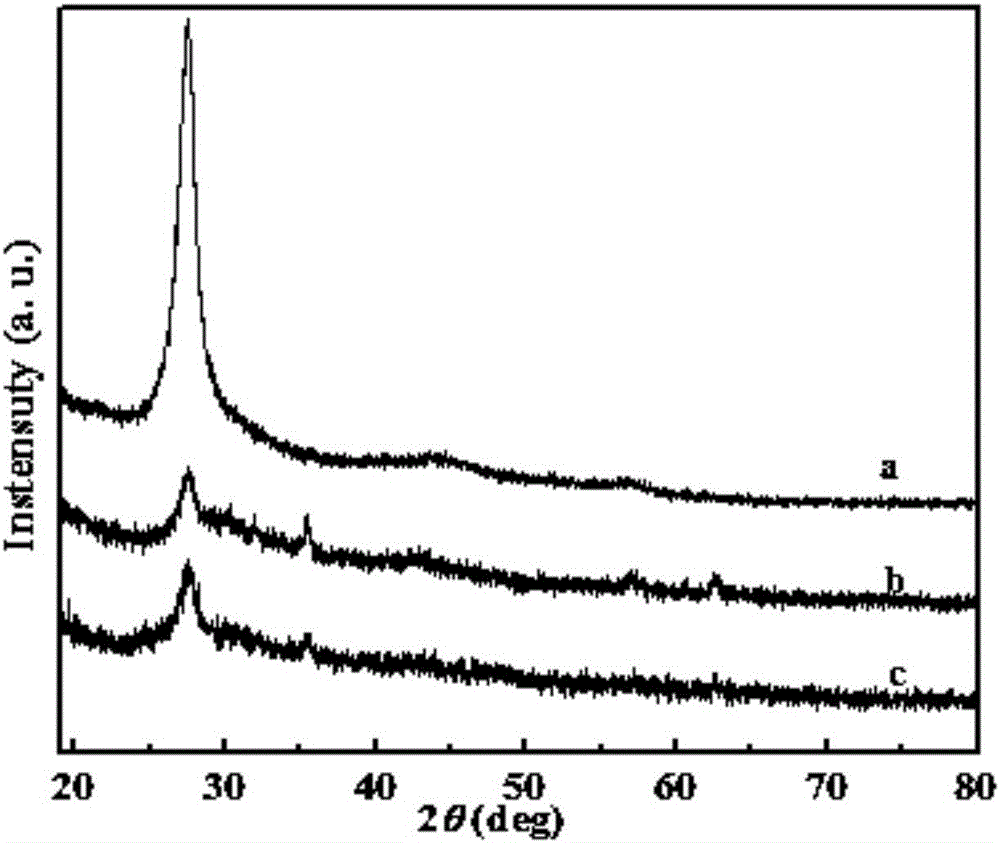

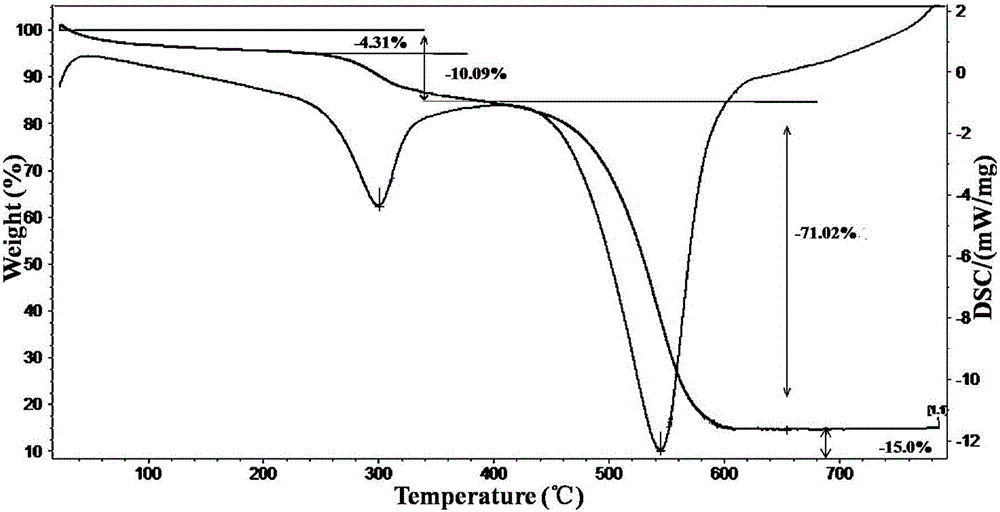

[0036] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Take 3 g of melamine and place it in a crucible, place it in a muffle furnace, and calcine it in an air atmosphere, raise the temperature to 500 °C at a heating rate of 2.3 °C / min, and keep it at a constant temperature for 2 hours, then at 550 °C Keep it at a constant temperature for 2 hours, cool down to room temperature naturally and grind it finely to get g-C 3 N 4 Photocatalyst, save for future use.

[0037] Step 2, the g-C prepared in step 1 3 N 4 Dispersed in ethylene glycol and sonicated to make g-C 3 N 4 suspension; the Fe(NO 3 ) 3 9H 2 O, polyvinylpyrrolidone (PVP), polyethylene glycol (PEG), and CH 3 COONa·3H 2 O dissolved in g-C respectively 3 N 4 in suspension; g-C 3 N 4 , ethylene glycol, Fe(NO 3 ) 3 9H 2 O, polyvinylpyrrolidone (PVP), polyethylene glycol (PEG), and CH 3 COONa·3H 2 The dosage of O is as follows: 1.5g, 30mL, 0.1g, 0.005g, 0.1g, 0.2g. Put it into a polytetrafluoroethylene re...

Embodiment 2

[0041] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Take 4 g of melamine and place it in a crucible, place it in a muffle furnace, and calcine it in an air atmosphere, raise the temperature to 450 °C at a heating rate of 2.5 °C / min, and keep it at a constant temperature for 2 hours, then at 500 °C Keep it at a constant temperature for 2 hours, cool down to room temperature naturally and grind it finely to get g-C 3 N 4 Photocatalyst, save for future use.

[0042] Step 2, the g-C prepared in step 1 3 N 4 Dispersed in ethylene glycol and sonicated to make g-C 3 N 4 suspension; the Fe(NO 3 ) 3 9H 2 O, polyvinylpyrrolidone (PVP), polyethylene glycol (PEG), and CH 3 COONa·3H 2 O dissolved in g-C respectively 3 N 4 in suspension; g-C 3 N 4 , ethylene glycol, Fe(NO 3 ) 3 9H 2 O, polyvinylpyrrolidone (PVP), polyethylene glycol (PEG), and CH 3 COONa·3H 2 The dosage of O is as follows: 3.0g, 50mL, 1.0g, 0.05g, 0.3g, 0.7g. Put it into a polytetrafluoroethylene rea...

Embodiment 3

[0046] Step 1. Preparation of g-C 3 N 4 Photocatalyst: Take 5 g of melamine and place it in a crucible, place it in a muffle furnace, and calcine it in an air atmosphere, raise the temperature to 480°C at a heating rate of 3°C / min, keep it at a constant temperature for 2 hours, and then heat it at 520°C Keep it at a constant temperature for 2 hours, cool down to room temperature naturally and grind it finely to get g-C 3 N 4 Photocatalyst, save for future use.

[0047] Step 2, the g-C prepared in step 1 3 N 4 Dispersed in ethylene glycol and sonicated to make g-C 3 N 4 suspension; the Fe(NO 3 ) 3 9H 2 O, polyvinylpyrrolidone (PVP), polyethylene glycol (PEG), and CH 3 COONa·3H 2 O dissolved in g-C respectively 3 N 4 in suspension; g-C 3 N 4 , ethylene glycol, Fe(NO 3 ) 3 9H 2 O, polyvinylpyrrolidone (PVP), polyethylene glycol (PEG), and CH 3 COONa·3H 2 The amount of O used is: 1.9g, 40mL, 0.45g, 0.02g, 0.2g, 0.35g. Put it into a polytetrafluoroethylene reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com