A method for quick assembly of rolling mill back-up rolls

An assembly method and technology of backup rolls, which are applied to metal rolling stands, metal rolling mill stands, metal rolling and other directions, can solve the problem of inability to accurately determine the relative positional relationship of the assembly parts, affecting the service life of the inner sleeve of the roll diameter and the bearing, The cold rolling production process is unstable and other problems, so as to avoid the bearing damage and the scratch of the inner sleeve of the roll diameter, improve the operation efficiency and reduce the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

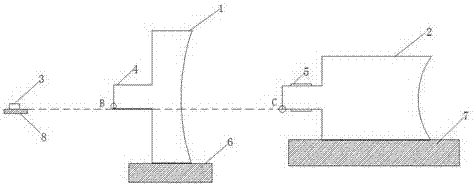

[0022] Such as figure 1 As shown, the first step: set the positioning point: place the bearing seat 1 on the horizontal lifting platform 6 of the bearing seat, and place the back-up roll 2 of the rolling mill on the horizontal assembly platform 7 of the back-up roll after grinding, so that the back-up roll 2 of the rolling mill is assembled One end of the diameter inner sleeve 5 is close to the bearing hole 4 of the bearing seat; the ray emitting device 3 is arranged on the lifting platform 8, and is located on the side of the bearing seat 1 away from the back-up roll 2 of the rolling mill, so that the ray emitting device 3 and the back-up roll 2 of the rolling mill are respectively located on the bearing The left and right sides of the seat 1; the lower end point of the roller diameter at which the end of the back-up roll 2 of the rolling mill is assembled with the roll diameter inner sleeve 5 is perpendicular to the horizontal plane as the positioning point C, and the ray emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com