Electromagnetic valve coil riveting machine

A technology of solenoid valve coils and riveting presses, which is applied in the field of riveting presses, can solve problems such as poor riveting pressure and low work efficiency, and achieve the effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

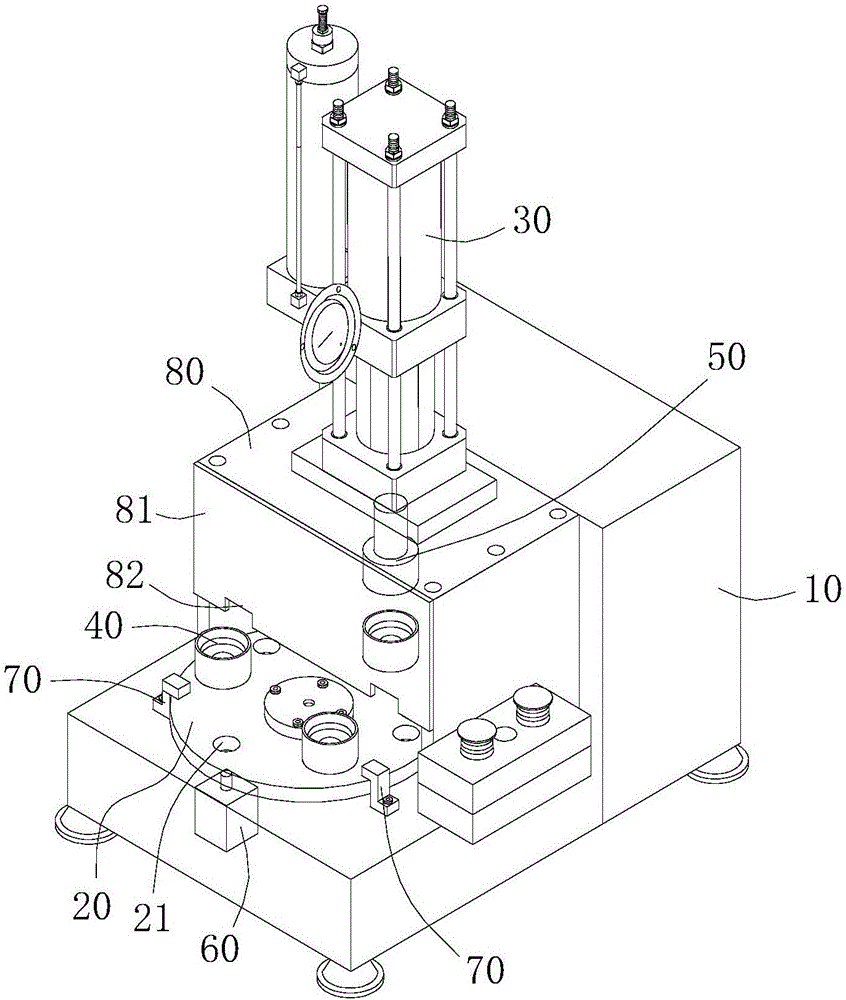

[0017] Such as figure 1 As shown, the solenoid valve coil riveting machine is composed of a frame 10 , a rotating disc 20 , a riveting cylinder 30 , a lower grinding tool 40 , an upper grinding tool 50 and a protective cover 80 .

[0018] The rotating disk 20 is connected to the frame 10 through a rotating shaft, and a servo motor is arranged inside the frame to precisely control the movement of the rotating disk. The lower grinding tools 40 are arranged on the top surface of the rotating disc. In this embodiment, three lower grinding tools are used, which are evenly distributed on the rotating disc in a circular manner. The protective cover 80 is located above the rotating disc, and the riveting cylinder 30 is arranged on the protective cover. The upper grinding tool 50 is connected to the piston end of the riveting cylinder 30, and the rive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com