Orbiting scroll structure capable of accurately positioning and work fixture thereof

A precise positioning, moving scroll technology, applied in positioning devices, manufacturing tools, clamping and other directions, can solve the problems of inconsistent positioning datum and detection datum, poor positioning accuracy, poor repeat positioning accuracy, etc., to achieve repeat positioning stability. And the effect of improving positioning accuracy, improving positioning accuracy, and eliminating poor positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

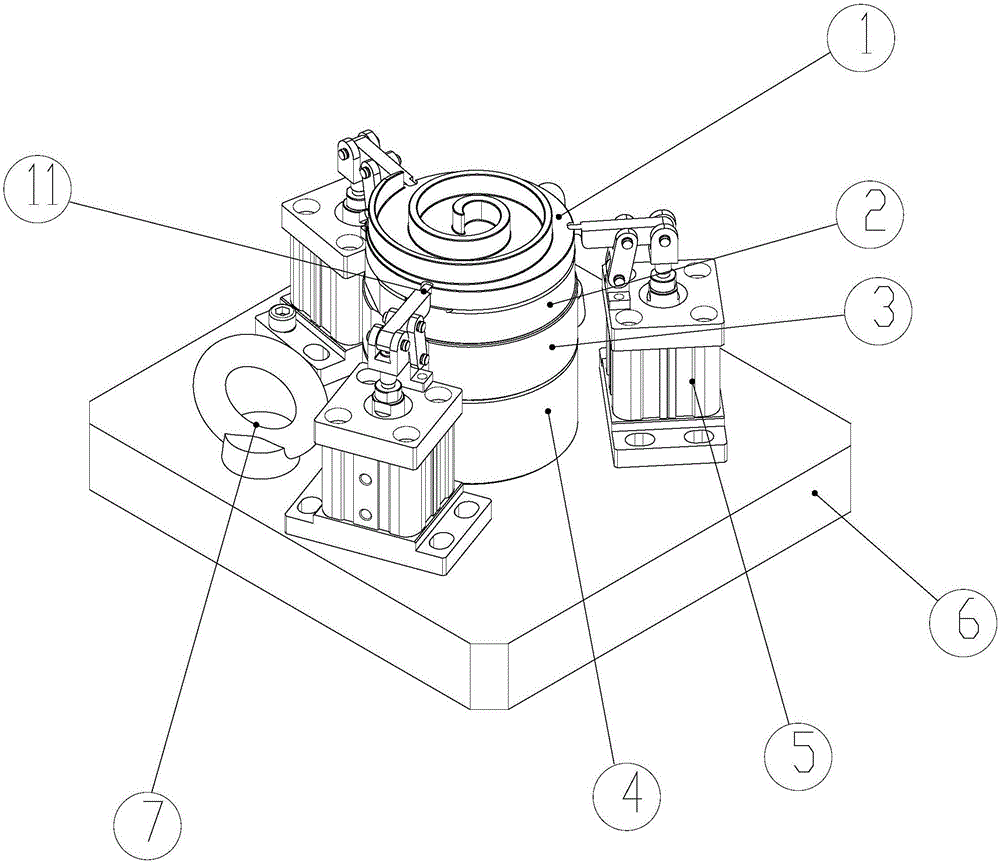

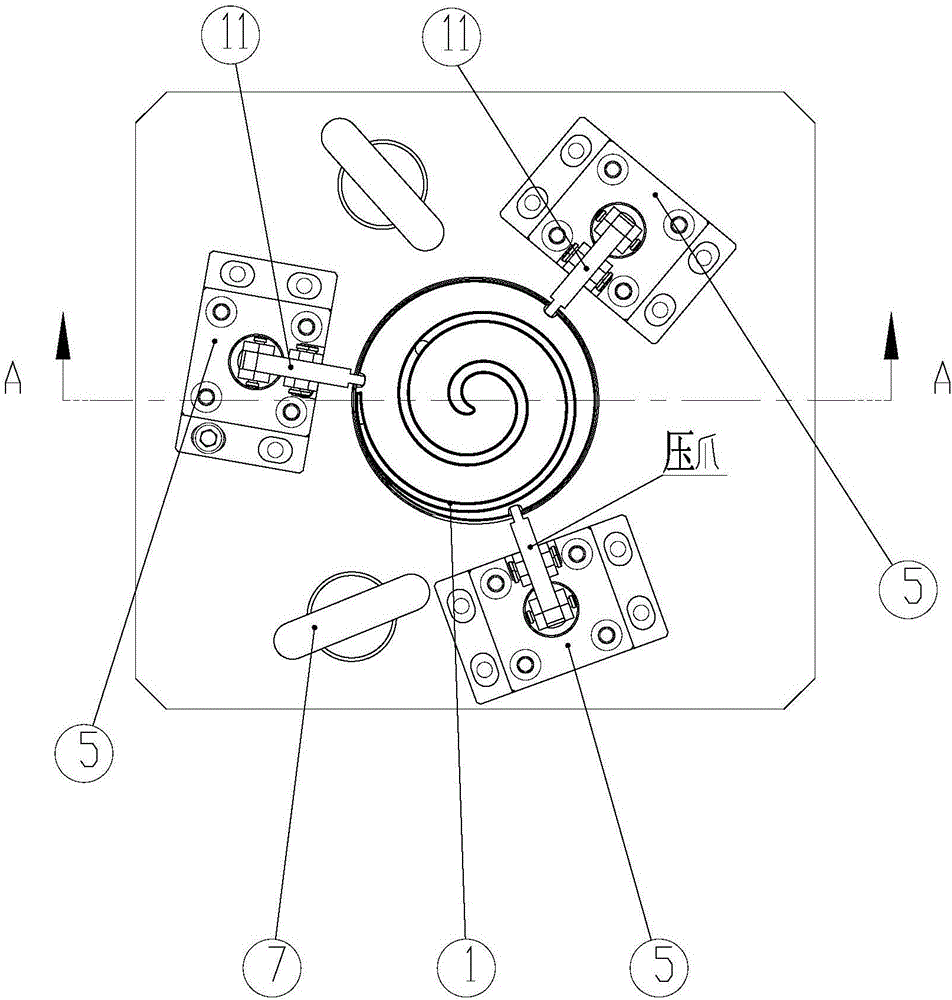

[0019] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

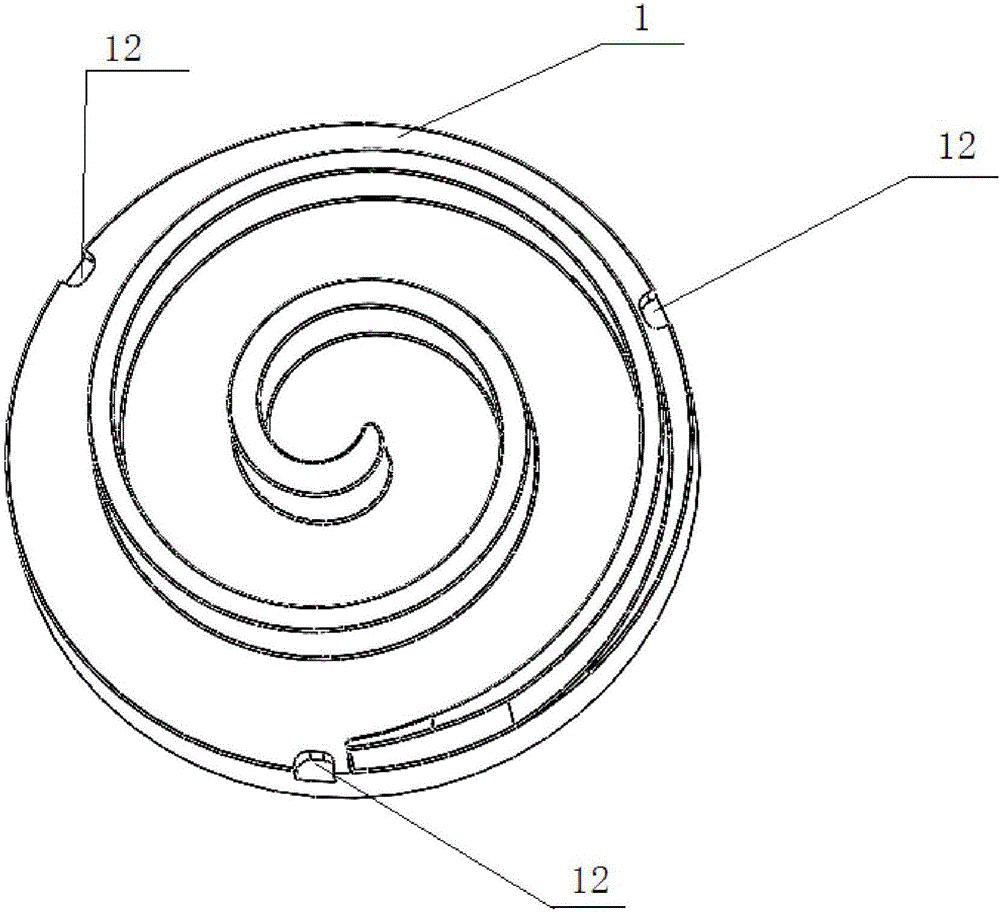

[0020] Such as Figure 1-Figure 4 As shown, a movable scroll structure that can be precisely positioned includes a movable scroll 1 , and several grooves 12 are arranged on the upper surface of the peripheral edge of the movable scroll 1 .

[0021] There are three grooves 12 which are evenly distributed on the circumference of the movable scroll 1 .

[0022] The positions of the three grooves 12 on the movable scroll 1 are determined after calculation and then simulated by the analysis and simulation software. The positions of the three grooves 12 cannot affect the use of the normal working surface of the movable scroll 1 . At the same time, the groove 12 can also be used as an oil groove to lubricate related components.

[0023] A fixture for positioning a movable scroll structure that can be precisely positioned, including a precision connecting plate 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com