Tool changing device for machine tool

A tool changing device and machine tool technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as loss, inconvenient control, easy breakage toughness, etc., to increase hardness, prevent breakage and torsion effect of breaking and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

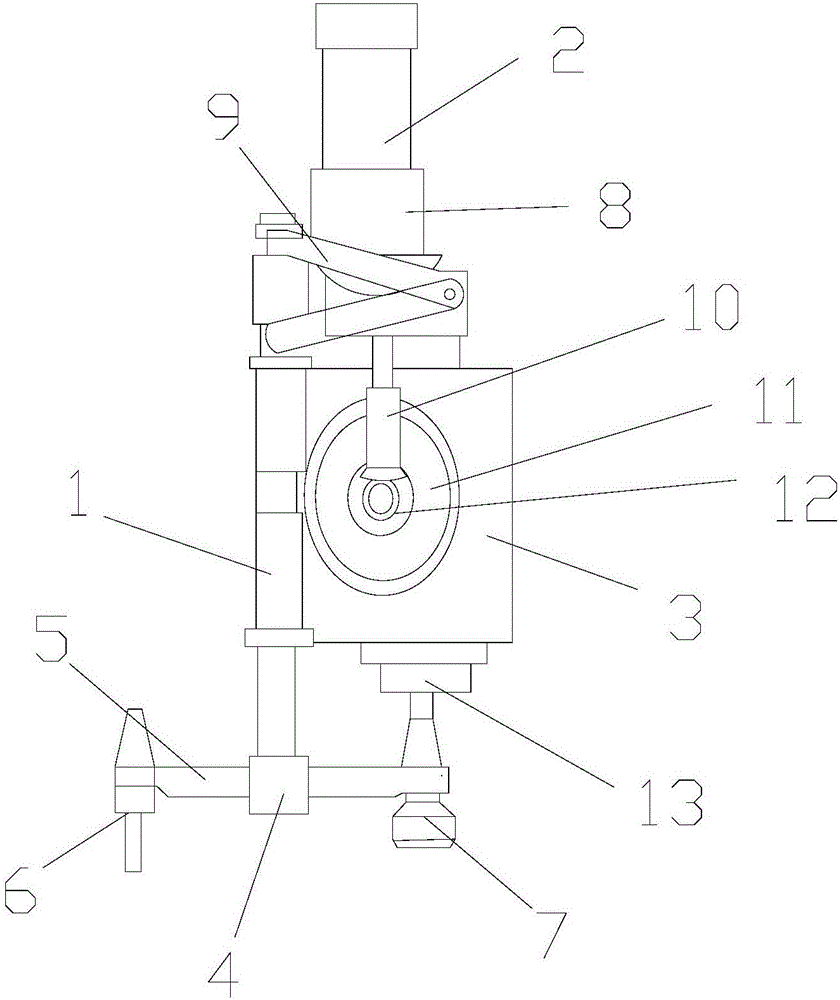

[0027] Such as figure 1 As shown, a tool changing device for a machine tool includes a main shaft 1, a drive motor 2 and a drive box 3. The main shaft 1 is located on the left side of the drive box 3 and is fixed with the drive box 3. The lower end of the main shaft 1 is arranged There is a barge joint 4, the two ends of the barge joint 4 are provided with jaws 5, the jaw 5 on the left side is provided with a spare tool 6, the jaw 5 on the right side is provided with a tool 7, and the drive motor 2 is located above the driving box 3, the lower end of the driving motor 2 is provided with a connecting seat 8, the connecting seat 8 is fixed with the driving box 3, the connecting seat 8 is provided with a movable rod 9, and the connecting seat 8 The lower end of the drive shaft 10 is provided with a drive shaft 10, the drive shaft 10 is located in the drive box 3, the drive box 3 is provided with a reduction wheel 11, the reduction wheel 11 is provided with a meshing gear 12, the ...

Embodiment 2

[0046] Such as figure 1As shown, a tool changing device for a machine tool includes a main shaft 1, a drive motor 2 and a drive box 3. The main shaft 1 is located on the left side of the drive box 3 and is fixed with the drive box 3. The lower end of the main shaft 1 is arranged There is a barge joint 4, the two ends of the barge joint 4 are provided with jaws 5, the jaw 5 on the left side is provided with a spare tool 6, the jaw 5 on the right side is provided with a tool 7, and the drive motor 2 is located above the driving box 3, the lower end of the driving motor 2 is provided with a connecting seat 8, the connecting seat 8 is fixed with the driving box 3, the connecting seat 8 is provided with a movable rod 9, and the connecting seat 8 The lower end of the drive shaft 10 is provided with a drive shaft 10, the drive shaft 10 is located in the drive box 3, the drive box 3 is provided with a reduction wheel 11, the reduction wheel 11 is provided with a meshing gear 12, the l...

Embodiment 3

[0065] Such as figure 1 As shown, a tool changing device for a machine tool includes a main shaft 1, a drive motor 2 and a drive box 3. The main shaft 1 is located on the left side of the drive box 3 and is fixed with the drive box 3. The lower end of the main shaft 1 is arranged There is a barge joint 4, the two ends of the barge joint 4 are provided with jaws 5, the jaw 5 on the left side is provided with a spare tool 6, the jaw 5 on the right side is provided with a tool 7, and the drive motor 2 is located above the driving box 3, the lower end of the driving motor 2 is provided with a connecting seat 8, the connecting seat 8 is fixed with the driving box 3, the connecting seat 8 is provided with a movable rod 9, and the connecting seat 8 The lower end of the drive shaft 10 is provided with a drive shaft 10, the drive shaft 10 is located in the drive box 3, the drive box 3 is provided with a reduction wheel 11, the reduction wheel 11 is provided with a meshing gear 12, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com