A meatball cutting machine

A flower cutting machine and meatball technology, which is applied in metal processing and other directions, can solve the problems of thickness, uneven size, easy rollover of cut flower pieces, large shape differences, etc. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

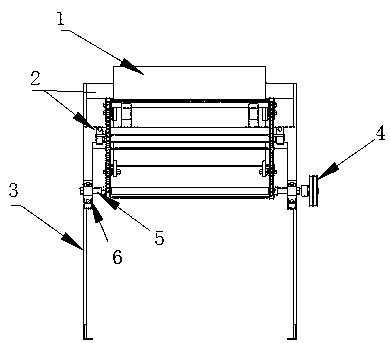

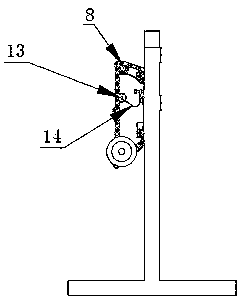

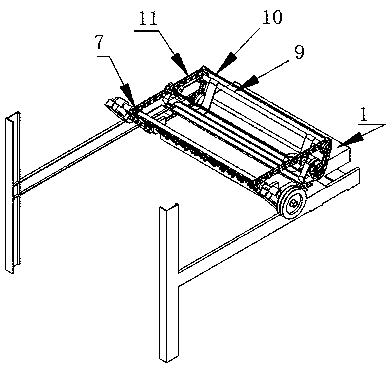

[0021] In the figure: a meatball cutting machine, including a frame 3, a hopper 17, a hopper 16, a lower hopper 15, a movement, the outlet of the hopper 17 is connected to the hopper 16, the other end of the hopper 16 is connected to the lower hopper 15, and the lower hopper 15 is connected to the Movement, the movement includes a material guide channel, a material pushing mechanism, and a cutter 12, and the material guide channel includes a front cover 24, a back cover 19, and a feed pipe 25, and the front cover 24 and the back cover 19 are installed on the frame, and the material guide channel The upper feed pipe 25 is a circular tube structure, and the lower part of the material guide channel has two front and rear parts, one is on the front cover 24, and the other is on the back cover 19. There is a meatball drop passage; the upper part of the meatball drop passage is connected with the lower hopper 15, and the lower part of the meatball drop passage is equipped with a cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com