Smart atomization water supplementing system suitable for CRTS 3 type pre-tensioned track board

A technology of water replenishment system and track plate, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as large fluctuation, warping deformation of plate body, difference in maintenance conditions of track plate, etc., and achieve a smooth and normal temperature curve and stable strength. Good, the effect of shortening the maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

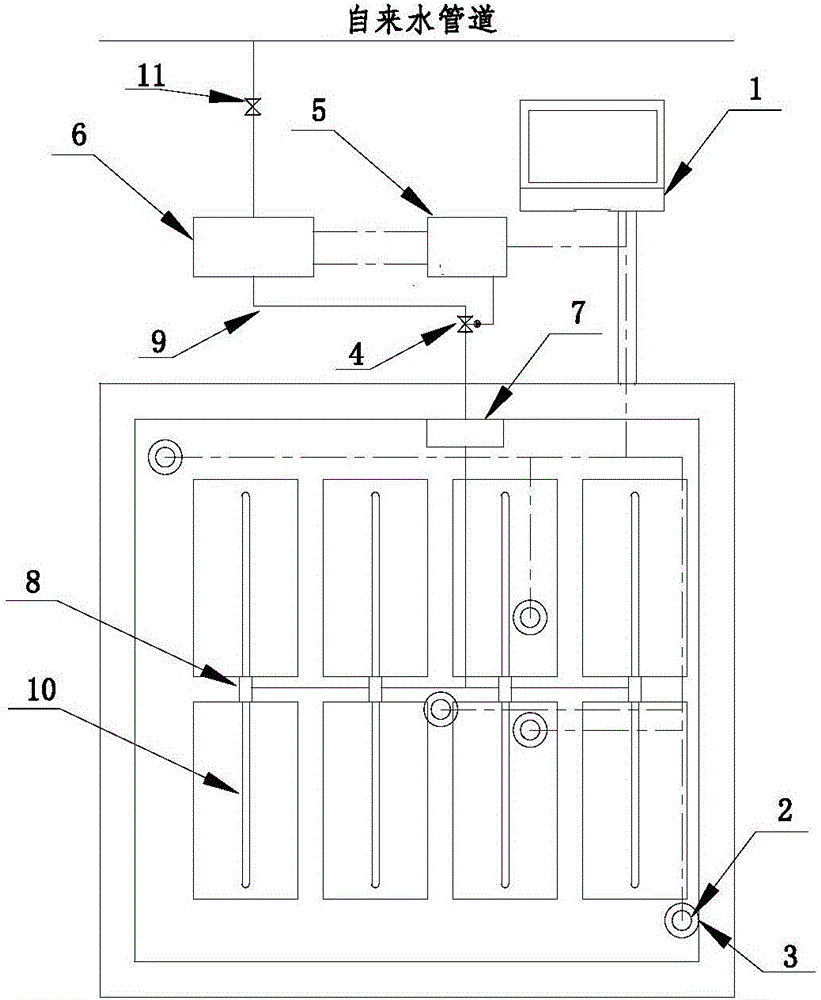

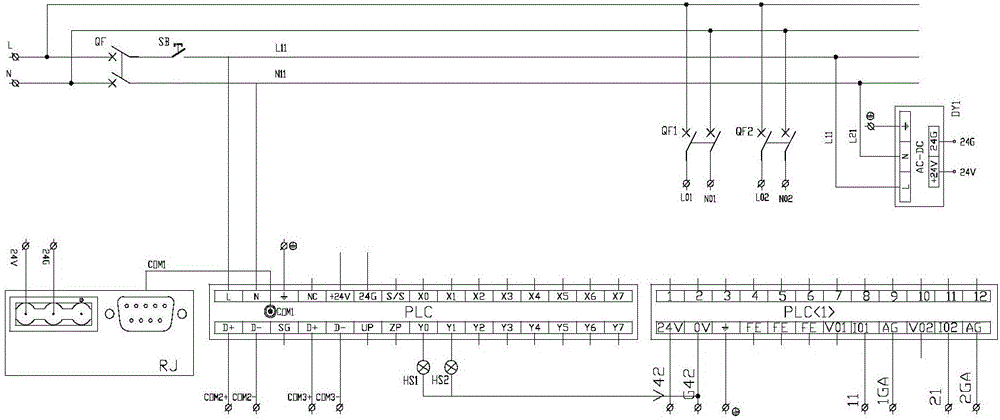

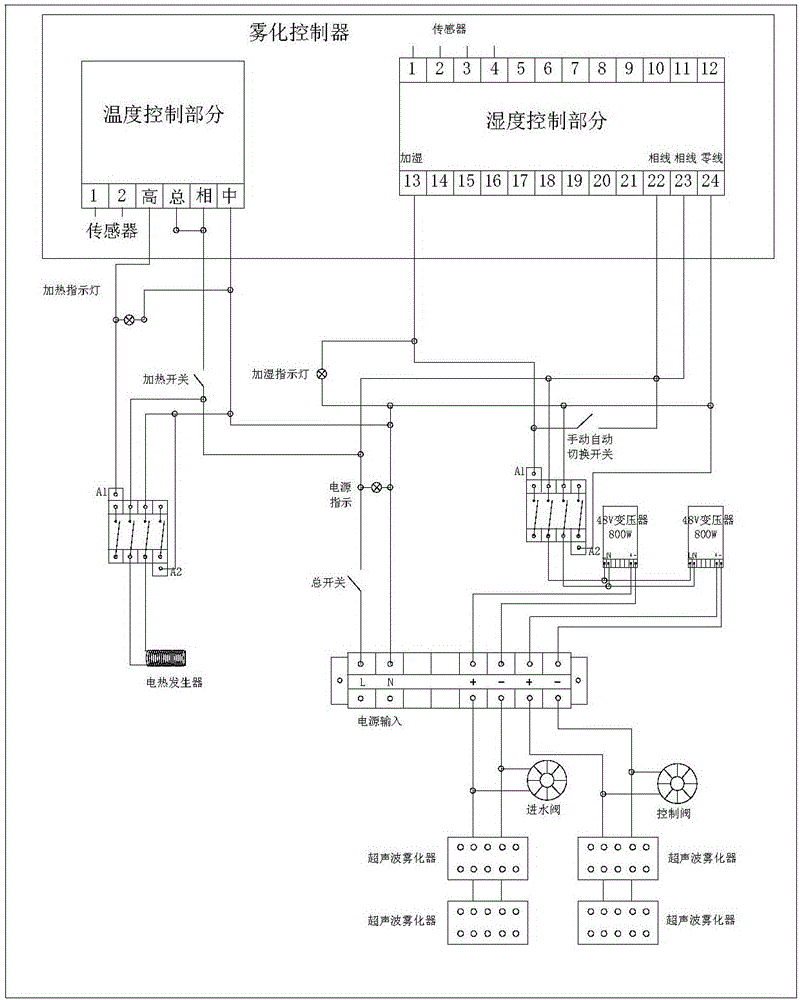

[0016] like figure 1 As shown, an intelligent atomization water replenishment system suitable for CRTSⅢ type pretensioning track plate, including the main control cabinet 1, control valve 4, ultrasonic atomizer 8, atomization controller 5, heating water tank 6, filter 7, Temperature sensor 2, humidity sensor 3, water pipe 9, mist guide pipe 10 and water inlet valve 11. Wherein, one port of the general control cabinet 1 is connected with the temperature sensor 2 and the humidity sensor 3 through a data line; the other port is connected with the atomization controller 5 . The temperature sensor 2 and the humidity sensor 3 are placed in the track plate pedestal to measure the temperature and humidity values near the track plate; the atomization controller 5 is connected to the heating water tank 6 and the control valve 4 through a data line, And cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com