Anti-collision buffering raw material barrel

A raw material barrel and anti-collision technology, which is applied in the direction of preventing mechanical damage to containers, unloading devices, bottle/can parts, etc., can solve the problems of low recycling rate, wear, barrel collision, etc., to improve utilization rate, Good sealing effect and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

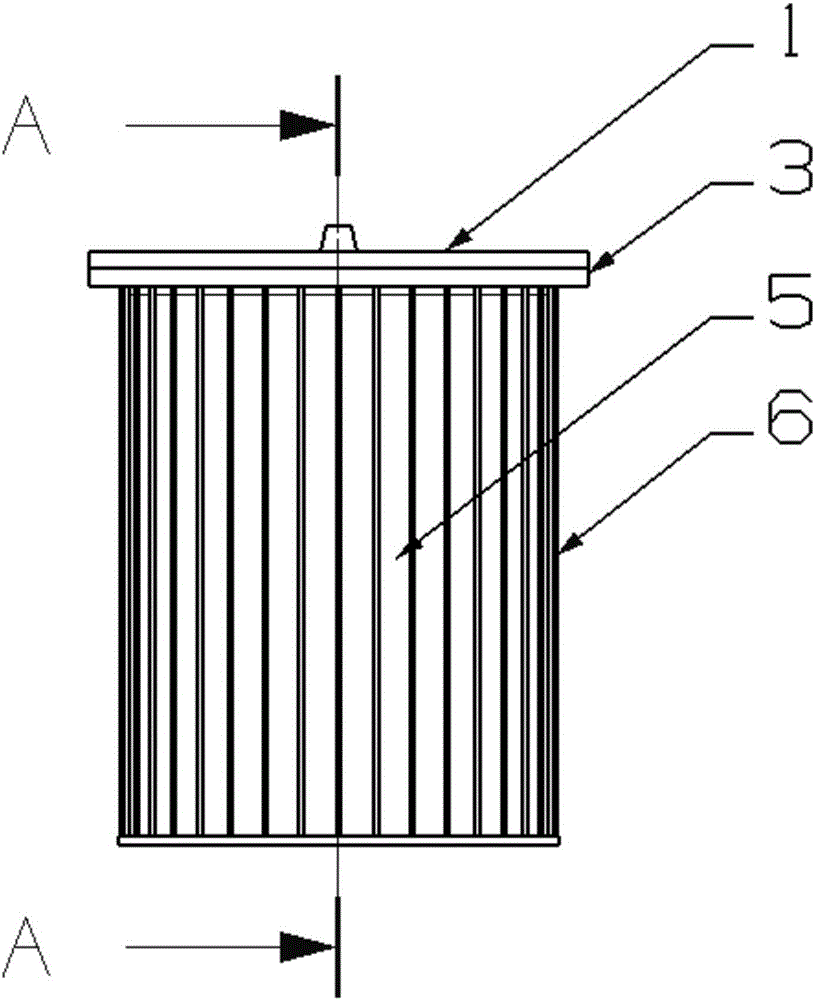

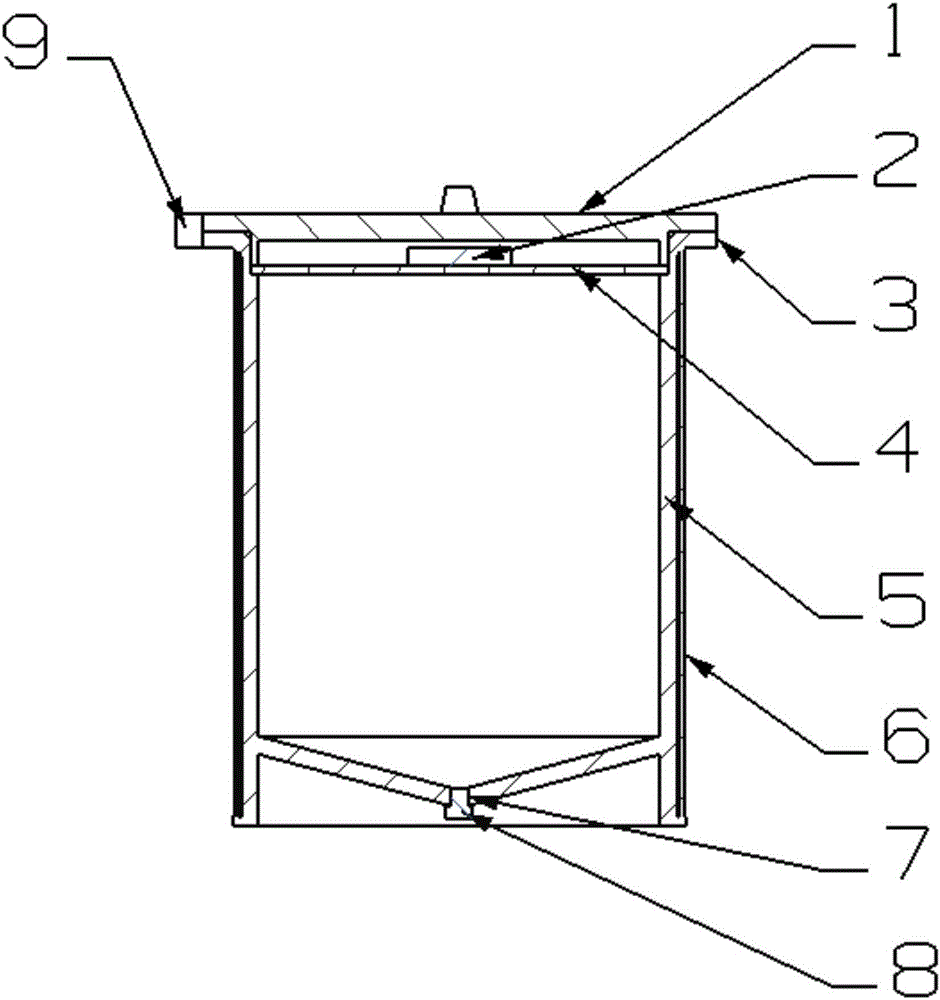

[0023] Such as figure 1 , figure 2 As shown, a kind of anti-collision cushioning raw material bucket described in the present invention includes: a bucket body 5 and a bucket cover 1, and the bucket cover 1 is fixed on the bucket body 5 through an outer hinge, and the top of the bucket body 5 The edge protrudes from the boss 3, a gasket 4 is arranged between the barrel body 5 and the lid 1, a drying device 2 is arranged in the center above the gasket 4, and a number of anti-collision bars 6 are arranged on the outside of the barrel body 5 , the shape of the bottom of the barrel body 5 is conical, and the boss 3 protruding from the top edge of the barrel body 5 is a full circle boss, and the center of the bottom of the barrel body 5 is provided with a threaded hole 7, and the threaded hole 7 is threadedly connected with the bolt 8, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com