Multifunctional pipeline communication and valve control structure for storage container

A storage container and valve control technology, which is applied in the field of installation of multi-functional container pipeline connection and valve control structure, can solve the problems of chaotic installation of pipeline valves, poor commonality of pipelines, waste of pipelines, etc., to avoid losses caused by deterioration, prevent deterioration problems, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

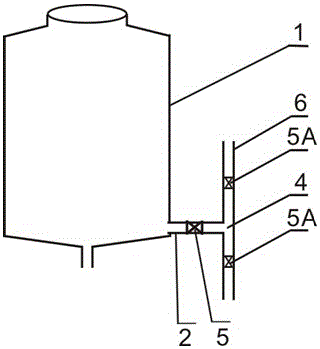

[0025] Embodiment one: if figure 1 As shown, a multifunctional pipeline connection and valve control structure of a storage container, including: a first inlet and outlet valve 5 fixedly connected to the storage container 1, a valve 5A for controlling the flow of liquid after the communication pipeline, an outlet pipeline 2, and a communication pipeline 6 An outlet pipe 2 is fixed above the discharge port at the bottom of the storage container 1. In this embodiment, the outlet pipe 2 is fixedly connected horizontally at a position 10 cm higher than the discharge port at the bottom of the storage container 1. A connecting pipe 6 is fixed on the outside of the outlet pipe 2 , and in this embodiment, the communicating pipe 6 is connected vertically. A valve 5 is fixed between the outlet pipe 2 and the communication pipe 6 , and valves 5A are respectively fixed at both ends of the connecting port of the communication pipe 6 , and a closed space 4 is formed in the pipe by closing t...

Embodiment 2

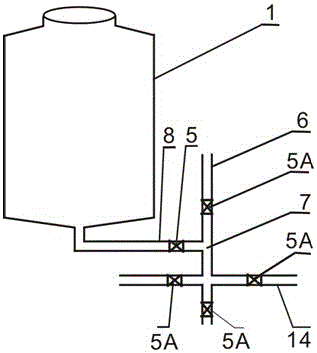

[0026] Embodiment two: if figure 2 As shown, a multifunctional pipeline communication and valve control structure of a storage container includes: a first inlet and outlet valve 5 connected to the storage container 1, a valve 5A for controlling the flow of liquid installed after the communication pipeline, an inlet and outlet pipeline 8, Connecting pipes (6, 14), the inlet and outlet pipes 8 are fixed at the bottom of the storage container 1, the other side of the inlet and outlet pipes 8 is fixed with a connecting pipe 6, and the connecting pipe 14 is fixed below the connecting pipe 6. A valve 5 is fixed between the outlet pipeline 8 and the communication pipeline 6, and valves 5A are respectively fixed on the outside of the communication opening of the communication pipeline (6, 14). By closing the valves (5, 5A), a closed space 7 is formed in the pipeline.

Embodiment 3

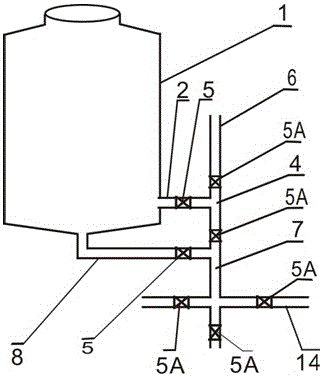

[0027] Embodiment three: as image 3 As shown, a multifunctional pipeline communication and valve control structure of a storage container, including: a first inlet and outlet valve 5 connected to the storage container 1, a valve 5A for controlling the flow of liquid after the communication pipeline, and inlet and outlet pipelines (2, 8) , connecting pipelines (6, 14), the inlet and outlet pipelines 8 are fixed at the inlet and outlet at the bottom of the container 1, the inlet and outlet pipelines 2 are fixed above the inlet and outlet at the bottom of the container 1, and the other sides of the inlet and outlet pipelines (2, 8) are respectively It is fixedly connected with the communication pipeline 6, and the communication pipeline 14 is fixed under the communication pipeline 6, and the valve 5 is respectively fixed between the inlet and outlet pipelines (2, 8) and the communication pipeline 6, and at the communication port of the communication pipeline (6, 14) Valves 5A ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com