Elevator car floor vibration-damping device and elevator

A vibration damping device and elevator car technology, which is applied to elevators in buildings, transportation and packaging, elevators, etc., can solve the problems of rubber shock absorbers such as high resistance, poor low temperature performance, no alarm for the car, and unstable stiffness. , to achieve good low-frequency vibration isolation performance, easy to sense deformation, and accurate and reliable weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

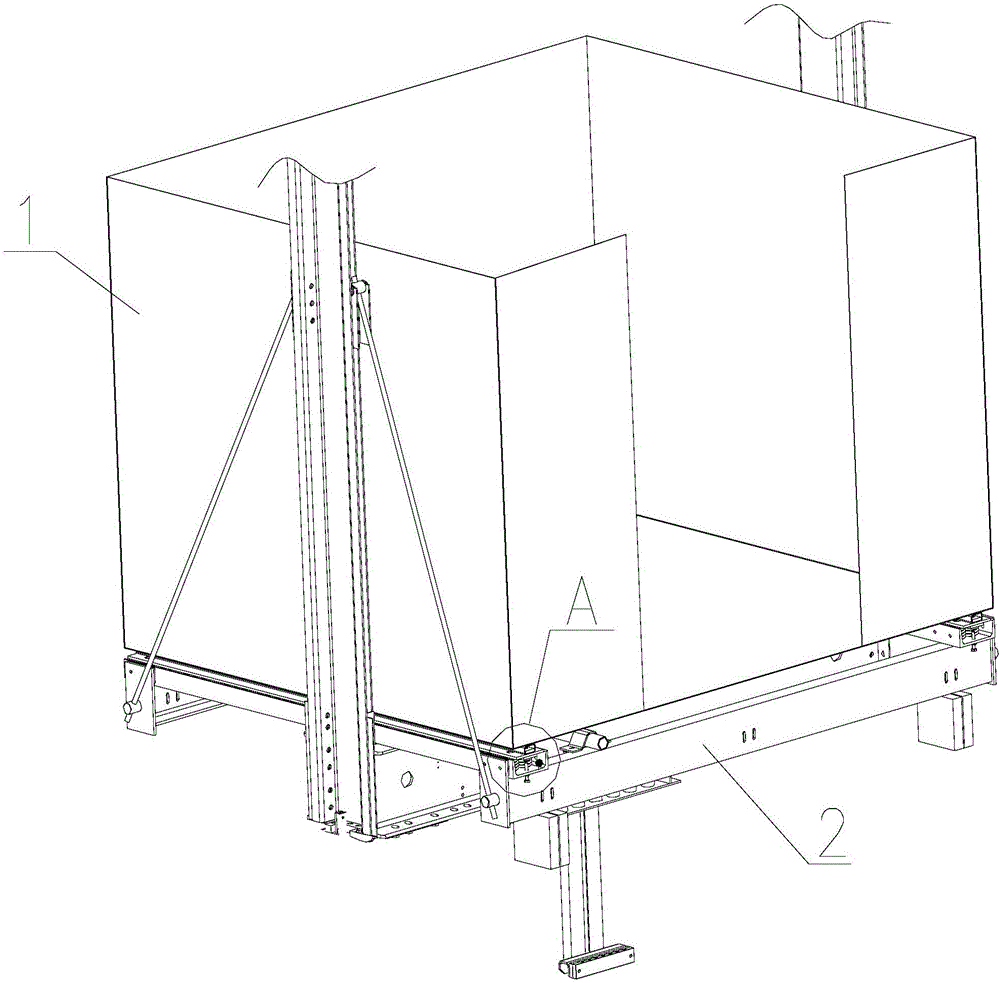

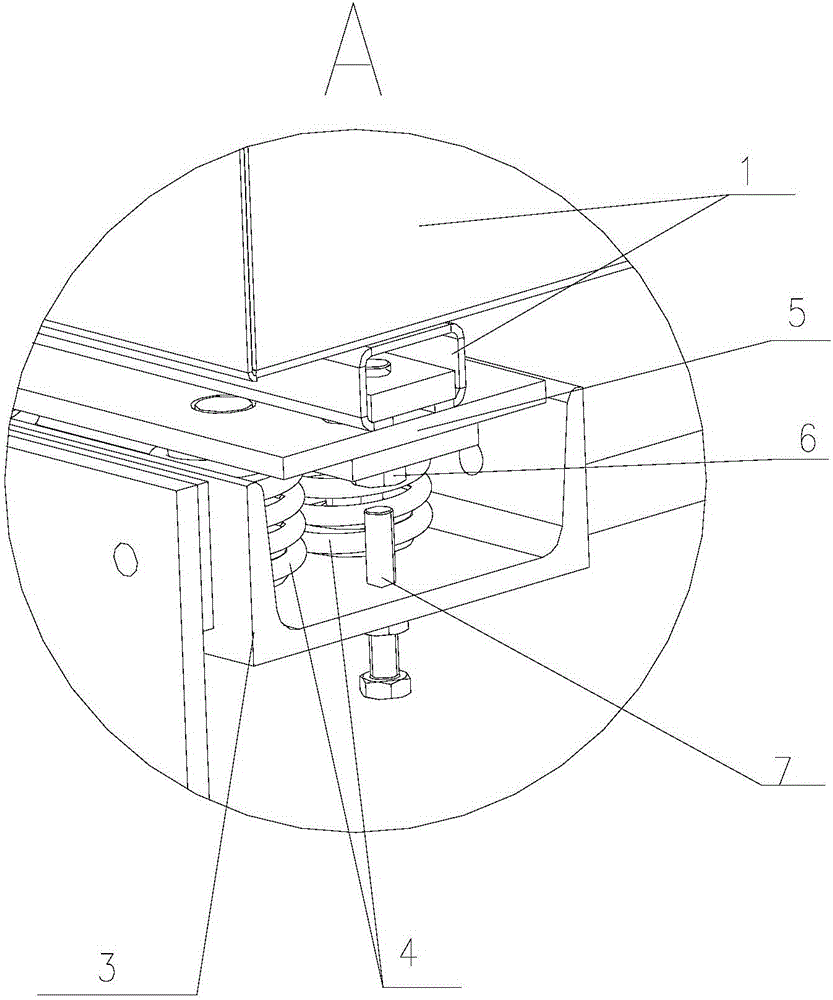

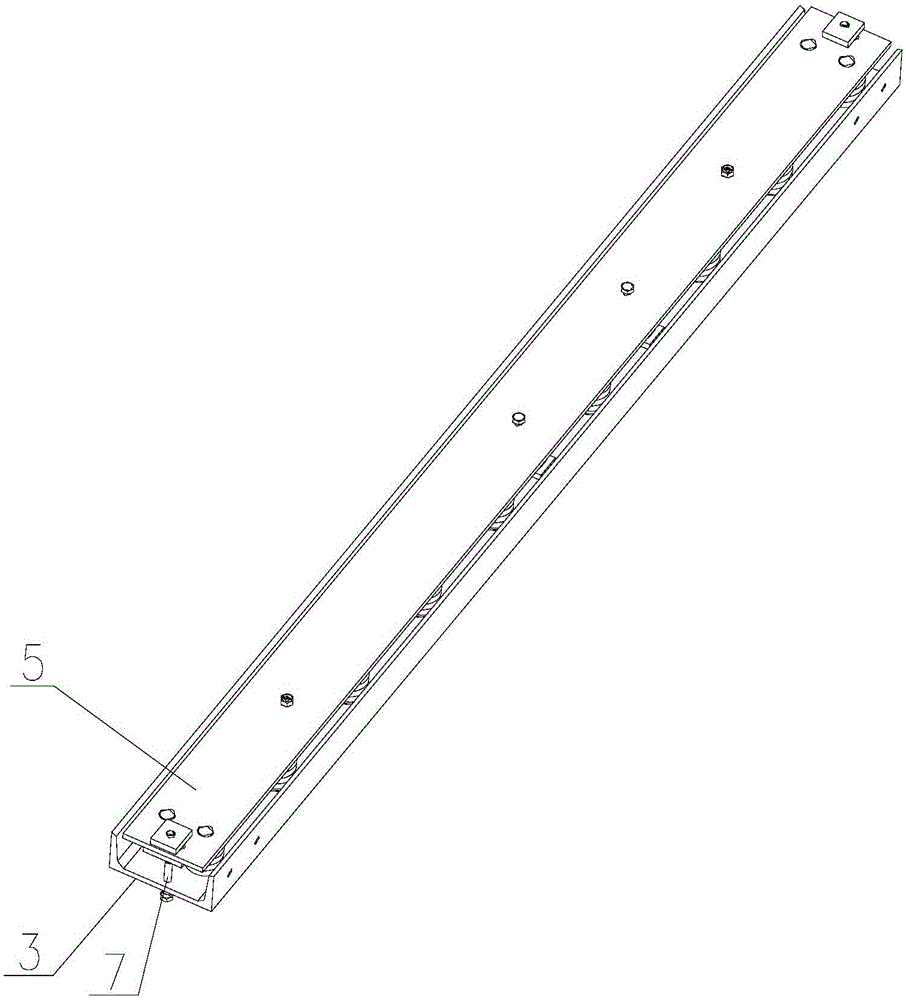

[0025] Such as figure 2 , 3 , 4, 5, 6, and 7, the elevator car bottom vibration damping device includes multiple groups of vibration damping components, each vibration damping component includes a lower bearing plate 3 fixedly installed on the car frame 2, and is fixed to the bottom of the car 1. Connected upper load-bearing plate 5, a plurality of springs 4 connected between the upper load-bearing plate 5 and the lower load-bearing plate 3, through the upper load-bearing plate 5 and the lower load-bearing plate 3 and the upper end is connected to the upper load-bearing plate The 5 phases are fixedly connected with the support column 8 whose lower end is located below the lower load-bearing block, and the rubber block that is sleeved on the lower end of the support column 8 and pressed between the lower end surface of the lower load-bearing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com