HDPE double-wall corrugated pipe and preparation technology thereof

A double-wall corrugated pipe and preparation process technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of lack of hardness, high cost of raw materials, and it is difficult to meet the standard of ring rigidity, and achieve simple and flexible raw materials. Good, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The HDPE double-wall corrugated pipe proposed by the present invention and its preparation process will be described in more detail below in combination with various preferred embodiments.

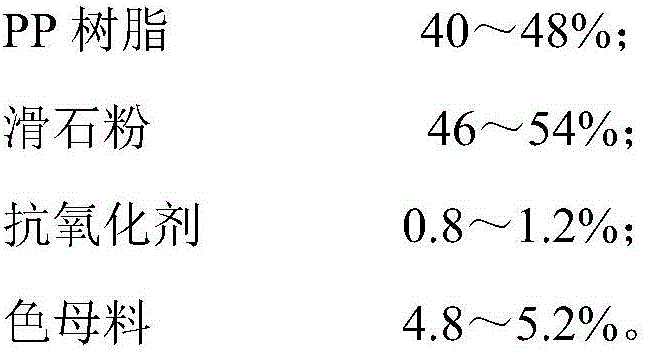

[0016] The invention provides a HDPE double-wall corrugated pipe, the raw materials of which are composed of 40-48% PP resin, 46-54% talcum powder, 0.8-1.2% antioxidant and 4.8-5.2% color masterbatch.

[0017] During specific implementation, the preparation process steps of the HDPE double-wall corrugated pipe are:

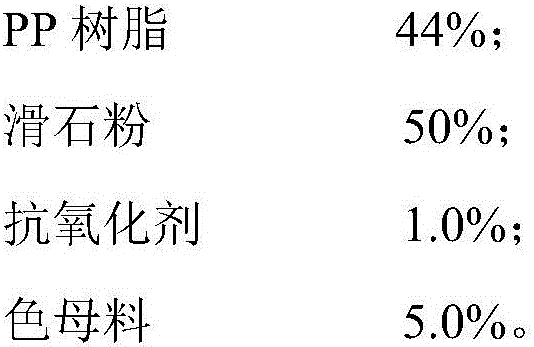

[0018] First, according to the raw material formula, take 44 parts of PP resin, 50 parts of talcum powder, 1 part of antioxidant, and 5 parts of color masterbatch and mix them evenly;

[0019] Secondly, the uniformly mixed raw materials are sent to the inner wall extruder and the outer wall extruder of the double-wall corrugated pipe to be plasticized at a temperature of about 190 degrees Celsius, and the inner wall molten material and the outer wall molten material ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com