Preprocessing method for producing ethyl alcohol through straw and application

A pretreatment and ethanol technology, applied in the direction of biofuels, fermentation, etc., can solve the problems of long treatment cycle, low treatment efficiency, low energy consumption of biological pretreatment, etc., to achieve convenient operation, low energy consumption, and avoid unsafe factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

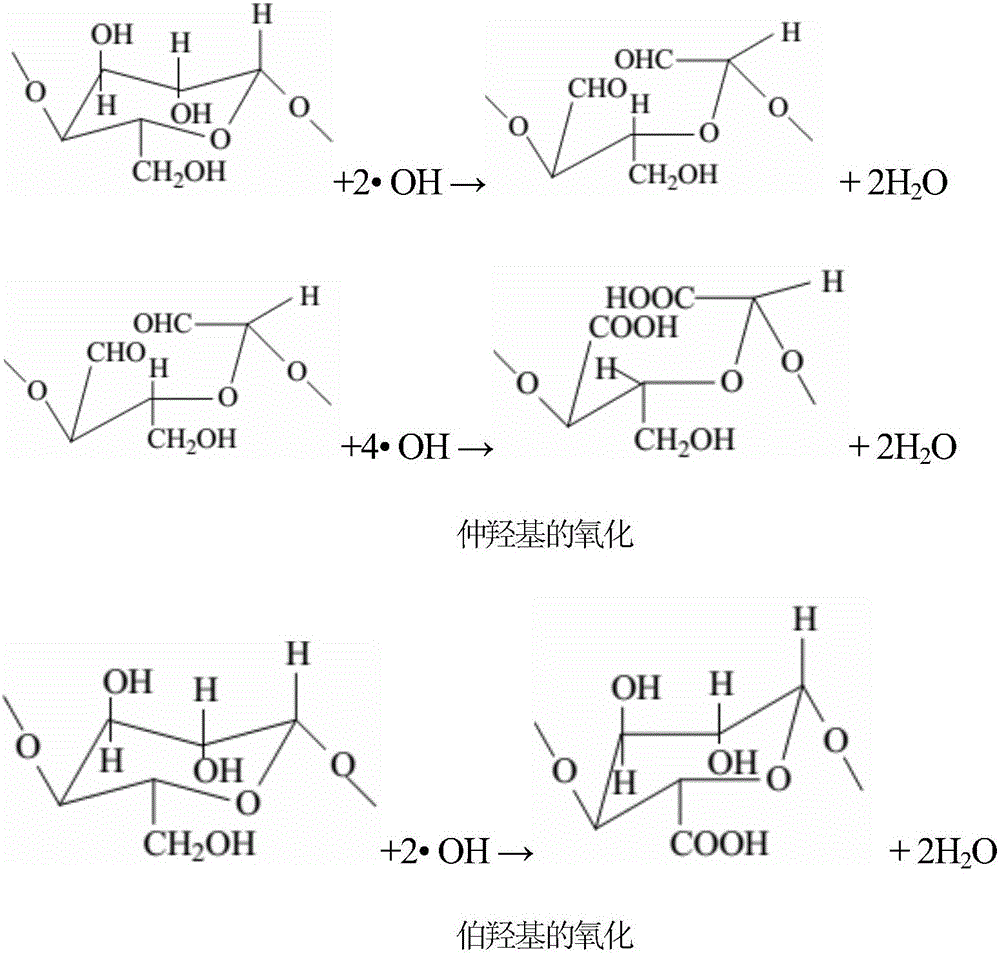

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the pretreatment method for producing ethanol from corn stalks comprises the following steps:

[0026] 1. Crush the corn stalks, pass through a 40# sieve, and place them in a desiccator for later use.

[0027] 2. In the preparation of 300mL Fenton's reagent: FeCl 2 The concentration is 1mmol, H 2 o 2 The concentration is 3wt%.

[0028] 3. Put 10 g of crushed and sieved corn stalks into the above solution, react at room temperature for 24 hours, vacuum filter, wash, and then dry at 105° C. to obtain pretreated corn stalks.

Embodiment 2

[0030] In this embodiment, the pretreatment method for producing ethanol from corn stalks comprises the following steps:

[0031] 1. Crush the corn stalks, pass through a 40# sieve, and place them in a desiccator for later use.

[0032] 2. In the preparation of 300mL Fenton's reagent: FeCl 2 The concentration is 2mmol, H 2 o 2 The concentration is 2wt%.

[0033] 3. Put 10 g of crushed and sieved corn stalks into the above solution, react at room temperature for 24 hours, vacuum filter, wash, and then dry at 50° C. to obtain pretreated corn stalks.

Embodiment 3

[0035] In this embodiment, the pretreatment method for producing ethanol from corn stalks comprises the following steps:

[0036] 1. Crush the corn stalks, pass through a 40# sieve, and place them in a desiccator for later use.

[0037] 2. In the preparation of 300mL Fenton's reagent: FeCl 2 The concentration is 3mmol, H 2 o 2 The concentration is 1wt%.

[0038] 3. Put 10 g of crushed and sieved corn stalks into the above solution, react at room temperature for 48 hours, vacuum filter, wash, and then dry at 80° C. to obtain pretreated corn stalks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com