Construction method for tunnel bridge construction joint sealing system

A construction method and technology for construction joints, applied in bridges, artificial islands, water conservancy projects, etc., can solve the problems of engineering social benefits and aesthetic effects, infiltration, water bleeding on the surface of concrete structures, etc., to achieve better waterproof effect and ensure waterproof effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The construction method of the tunnel bridge construction joint water stop system provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

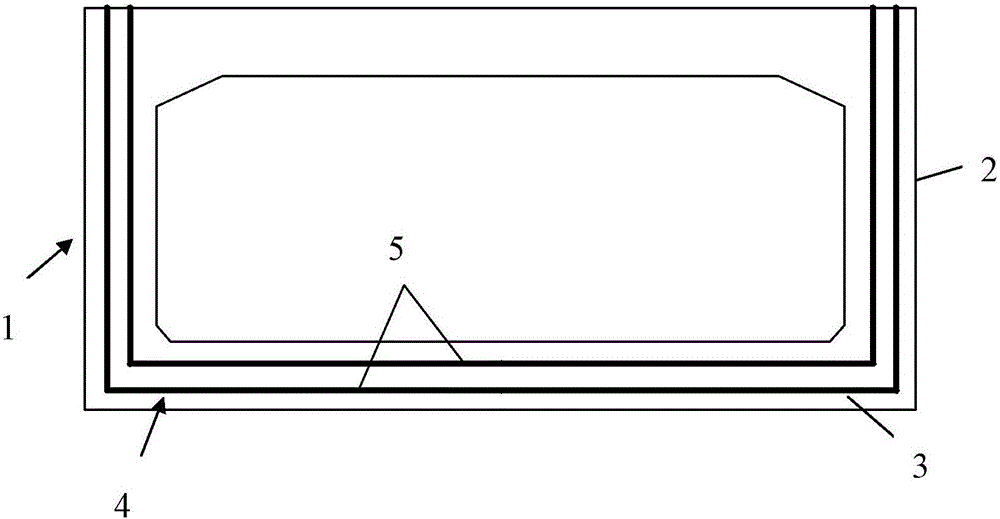

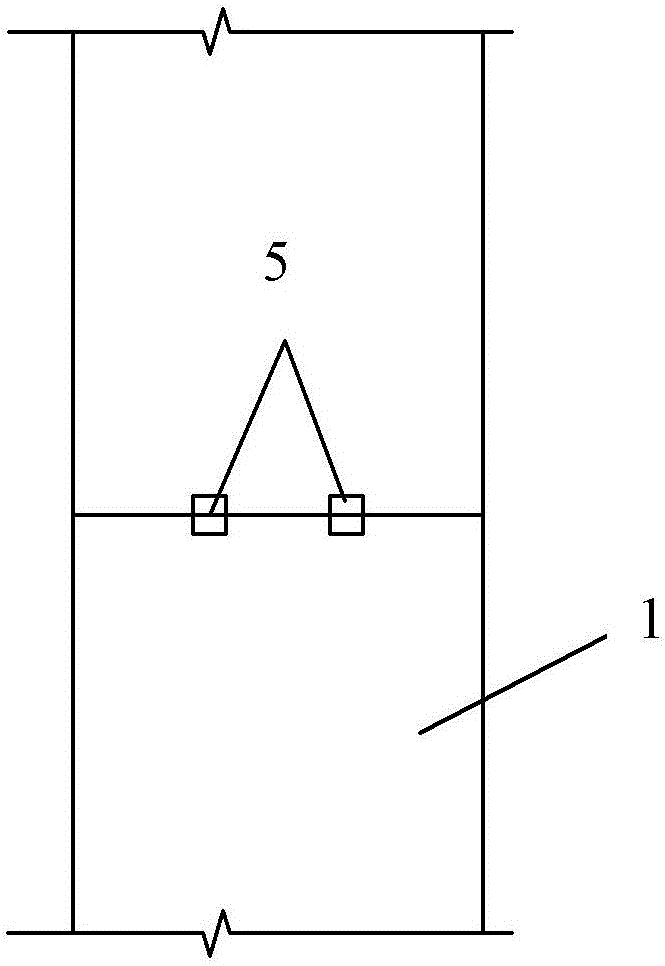

[0019] Such as figure 1 — figure 2 As shown, the tunnel bridge construction joint water-stop system construction method provided by the present invention includes the following steps carried out in order:

[0020] 1) The front and rear end faces of the side wall 2 and the bottom plate 3 of the frame bridge 1 are manually chiseled with a pick, and two U-shaped grooves 4 are formed on the end face, and the laitance is removed and stones are exposed; Clean up the debris after removal, use the air pump to blow and brush the surface, and rinse with water after cleaning the loose concrete debris;

[0021] 2) Install a water-swellable water-stop strip 5 in each of the above-mentioned U-shaped grooves 4, and ensure that the water-swellable water-stop stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com