Ground anchor and counter-force loading type soft foundation prepressing treatment method

A technology of counter force loading and soft foundation treatment, which is applied in the direction of foundation structure engineering, soil protection, sheet pile walls, etc., can solve the problems of high technical requirements, limited treatment effect and shallow treatment depth of vacuum preloading method, and achieve Good engineering adaptability, beneficial to soil consolidation, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and implementation steps.

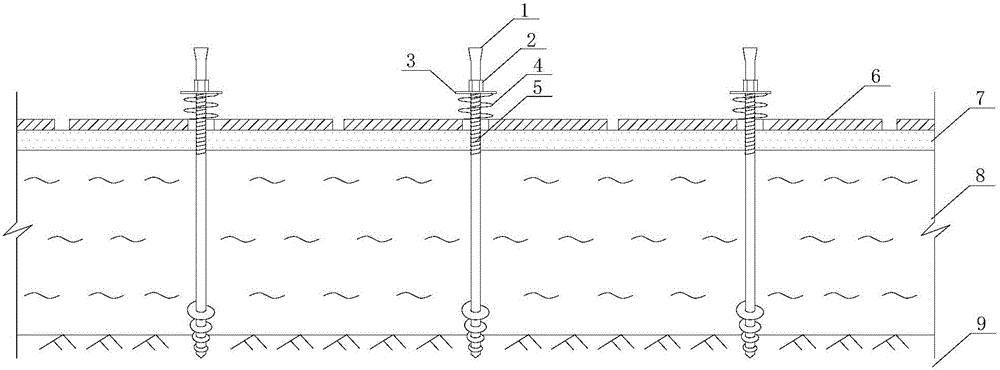

[0029] Such as figure 1 As shown in , it is a cross-sectional schematic diagram of the weak soil foundation treated by the ground anchor counter force loading preloading method. The invention is divided into two parts, a specially designed ground anchor and a soft soil foundation counter force loading preloading method based on the ground anchor.

[0030] The ground anchor includes a conventional ground anchor 1, the main difference of which is that the upper part of the ground anchor 1 shaft is provided with a force component and a counter force loading device, and the counter force loading device applies an upward pull to the ground anchor 1 through the force component. Force, using the pull-out resistance of the ground anchor itself, and transmitting the reaction force of the pull-up force to the bottom of the reaction force loading device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com