Miniature jet grouting pile group and implementation method

A technology of miniature piles and rotary grouting piles, which is applied in the engineering field, can solve the problems of poor pile-soil coordination deformation and force transmission performance, easy corrosion of reinforcement materials, and easy loss of soil between piles, etc., so as to improve the anti-sliding ability and improve The effect of deformation coordination ability and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

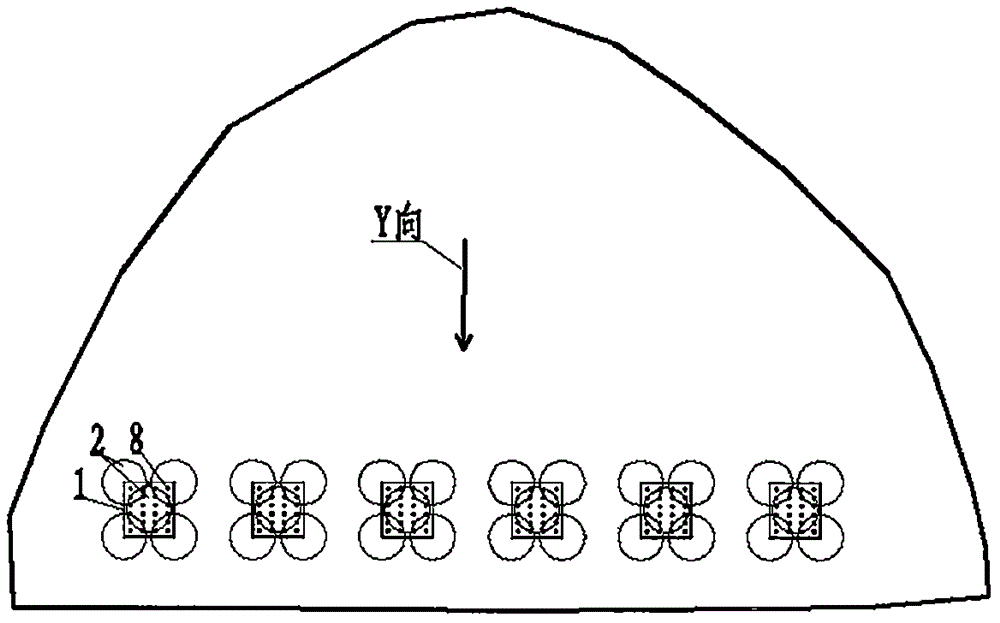

[0025] like figure 1 As shown, the Y direction in the figure is the main sliding direction.

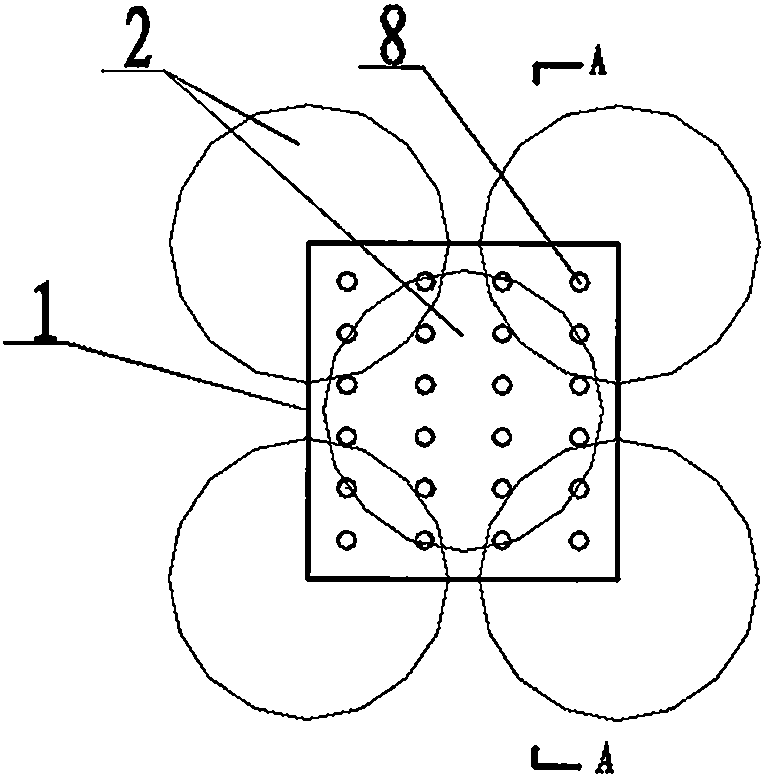

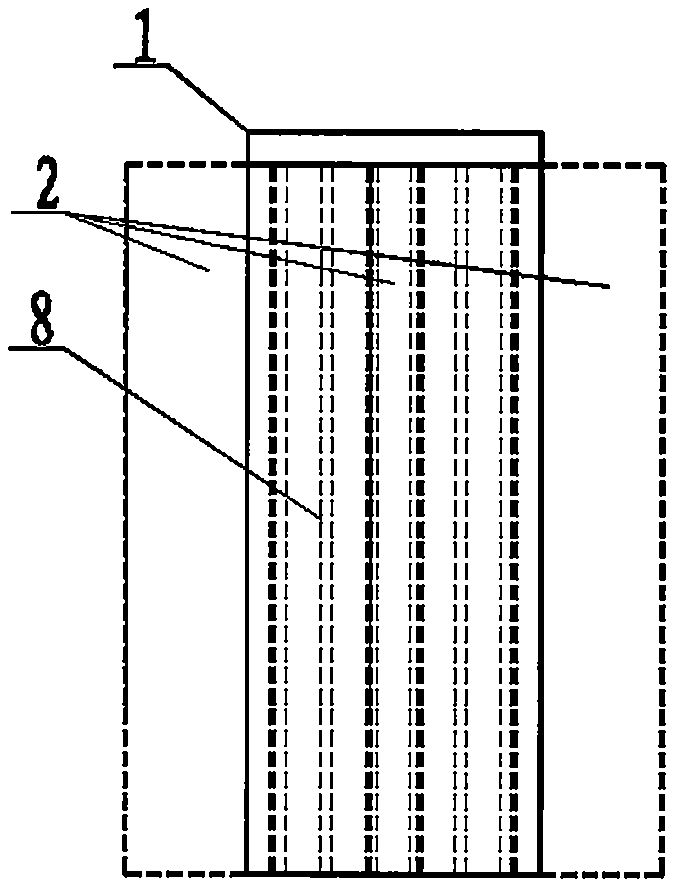

[0026] The utility model relates to a spin-spraying miniature pile group, in which a plurality of miniature pile reinforcing materials (8) are combined to form a rectangular miniature pile group. Arrange five rotary grouting piles (2) at the four corners of the micro pile group and the center of the pile group to solidify the soil between the micro piles.

[0027] The micro pile reinforcement (8) passes through the sliding body (5), the sliding surface (6) and extends into the sliding bed (7).

[0028] In the present embodiment, the length of the micro-pile reinforcing material (8) stretching into the sliding bed (7) is not less than 1 / 2 of the length of the micro-pile reinforcing material (8). The arrangement spacing of the micro-pile reinforcing materials (8) parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com