Solid wood multi-layer composite floor and preparation process and assembly method thereof

A preparation process, multi-layer composite technology, applied in the direction of floor, building, building structure, etc., can solve the problems of high rejection rate, complex multi-layer solid wood composite floor process, unstable locking performance, etc., to reduce the rejection rate , Guarantee dimensional stability, improve the effect of easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

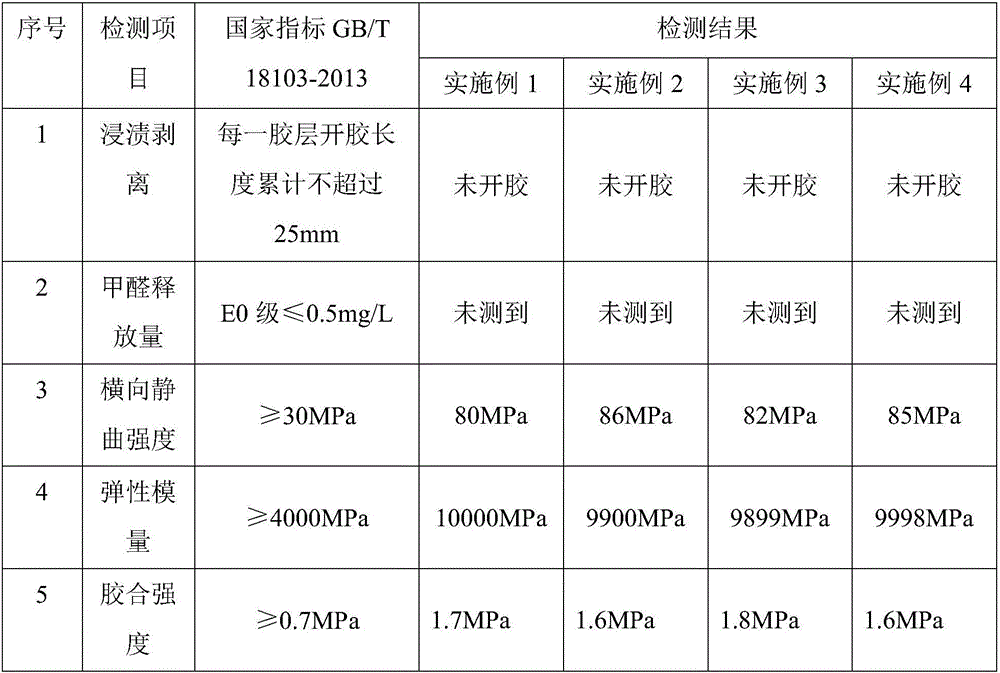

Examples

Embodiment 1

[0019] A preparation process for solid wood multilayer composite flooring comprises the following steps:

[0020] (1) Preparation of raw materials: The raw materials are first inspected and divided into equal parts, and unqualified materials with insect eyes, decay and excessive defects are removed.

[0021] (2) Selection of solid wood panels: Multi-layer solid wood composite floors are mostly used in the dry environment in the north, so dimensional stability is extremely critical. In order to prevent cracking and other phenomena in the dry heating season, it is necessary to select one by one, and strictly control the moisture content between 6% and 13%.

[0022] (3) Selection of the base plate: Choose a base plate with no defects and no fractures.

[0023] (4) Rotary cutting and drying of logs: The quality of the base solid wood core board is inseparable from the quality of the finished floor. The solid wood core board cut out by rotary cutting is about 2.2mm thick. It will ...

Embodiment 2

[0032] A preparation process for solid wood multilayer composite flooring comprises the following steps:

[0033] (1) Preparation of raw materials: The raw materials are first inspected and divided into equal parts, and unqualified materials with insect eyes, decay and excessive defects are removed.

[0034](2) Selection of solid wood panels: Multi-layer solid wood composite floors are mostly used in dry environments in the north, so dimensional stability is extremely critical. In order to prevent cracking and other phenomena in the dry heating season, one should be selected one by one, and the moisture content should be strictly controlled between 6% and 13%.

[0035] (3) Selection of the bottom plate: choose a bottom plate with no defects and no fractures.

[0036] (4) Rotary cutting and drying of logs: The quality of the base solid wood core board is inseparable from the quality of the finished floor. The thickness of the solid wood core board cut by rotation is about 2.2 ...

Embodiment 3

[0045] A preparation process of a solid wood multi-layer composite floor comprises the following steps:

[0046] (1) Preparation of raw materials: The raw materials are first inspected and divided into equal parts, and the unqualified materials with insect eyes, decay and excessive defects are removed.

[0047] (2) Selection of solid wood panels: Multi-layer solid wood composite floors are mostly used in dry environments in the north, so dimensional stability is extremely critical. In order to prevent cracking and other phenomena in the dry heating season, one should be selected one by one, and the moisture content should be strictly controlled between 6% and 15%.

[0048] (3) Selection of the bottom plate: choose a bottom plate with no defects and no fractures.

[0049] (4) Rotary cutting and drying of logs: The quality of the base solid wood core board is inseparable from the quality of the finished floor. The thickness of the solid wood core board cut by rotation is about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com