Device and method for restraining vortex-induced vibration of marine riser through upward-going energy of drilling fluid

A technology of energy suppression and vortex-induced vibration, applied in drill pipes, drilling equipment, drill pipes, etc., can solve the problems of increasing flow resistance, consumption, changing the weight of pipe strings, etc., to achieve zero energy consumption and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

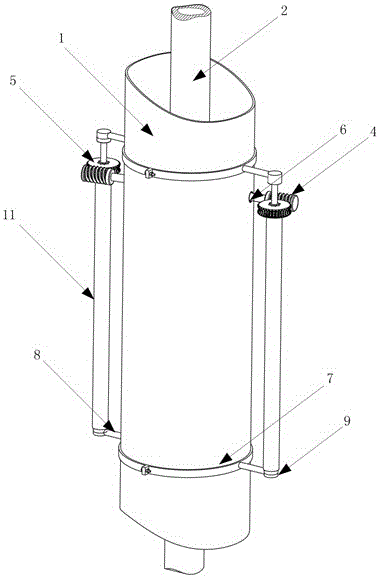

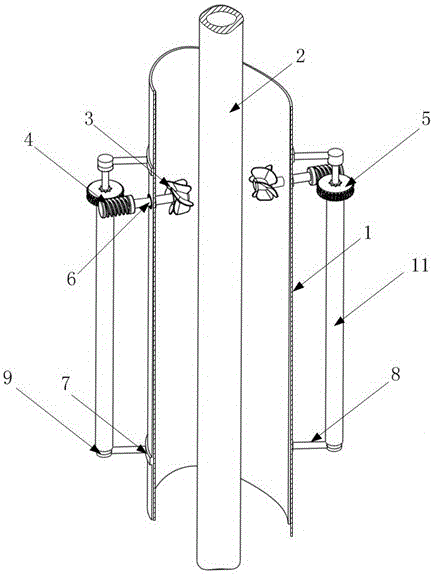

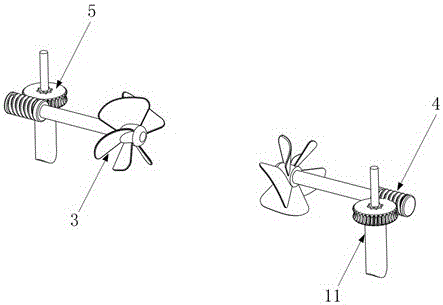

[0023] The device of the present invention can be used as a basic unit, and multiple units are arranged on the riser 1 at certain intervals according to actual needs, so as to realize segmental suppression of the vortex-induced vibration of the riser 1 . During actual installation, two round holes arranged axially symmetrically are first opened on the pipe wall of riser 1, and one end of worm 4 is extended from the round hole into the annular space between riser 1 and drill pipe 2, and The impeller 3 is mounted on the end of the worm 4. Then, the gap between the worm 4 and the circular hole on the pipe wall of the riser 1 is filled with the sealed bearing 6 . The outer wall of the riser 1 is spaced with two collars 7 at the upper and lower parts, and a rotating bearing 10 is arranged in the bearing seat 9 at the end of the support rod 8 of the collar 7 . Pass the small-diameter cylinder at the upper end of the spoiler rod 11 through the central hole of the worm wheel 5, inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com