System and Method for Measuring Performance Parameters of Synchronous Grouting in Shield Tunnel

A technology of simultaneous grouting and shield tunneling, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of large accidental errors in measurement, large manual operation errors, and cumbersome operation procedures, and achieve real-time and convenient acquisition and convenience. The effect of management and control, which is conducive to accumulation and communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

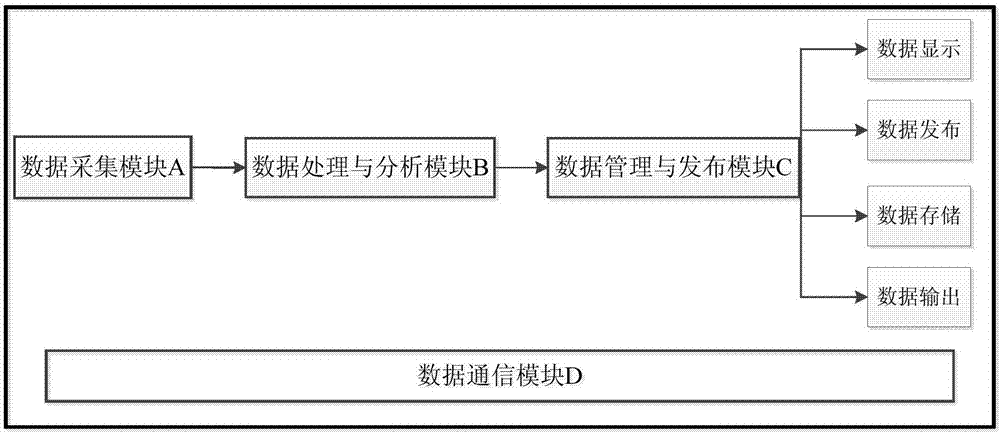

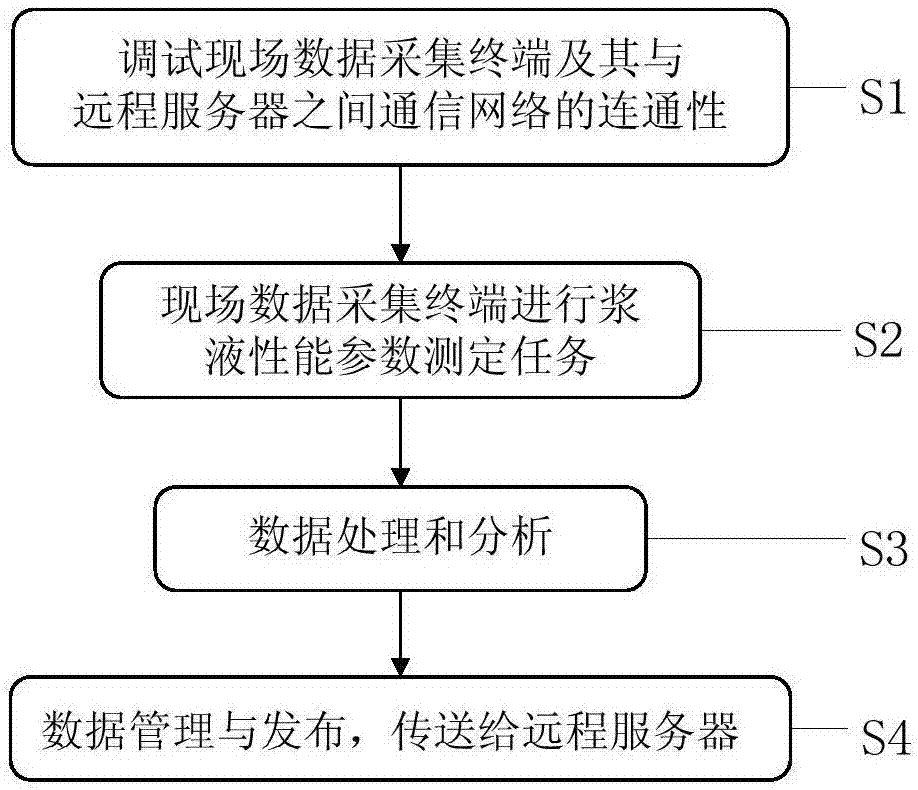

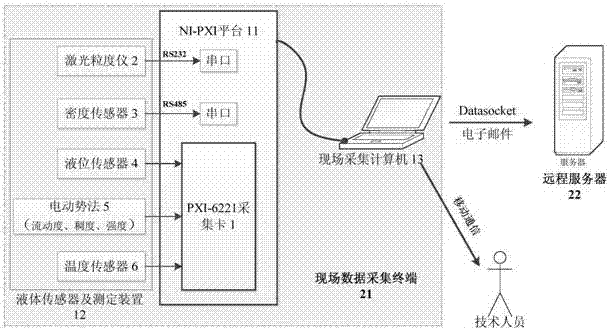

[0029] The present invention relates to a shield tunnel synchronous grouting grout performance parameter measurement system, comprising an on-site data acquisition terminal 21 and a remote server 22, and the on-site data acquisition terminal 21 and the remote server 22 communicate through a wireless Internet connection. The on-site data collection terminal 21 is used to integrate the data collection module A, data communication module B, data processing and analysis module C, and data management and release module D that are connected and communicate with each other, so as to realize the main module functions of the slurry performance parameter test; the remote server 22 is used to receive the data measured by the on-site collection terminal 21, process, analyze and store it, and also has the function of remotely controlling the on-site data col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com