Full-automatic continuous rock output system

A fully automatic and hydraulic system technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve the problems of frequent start-up of equipment, many intermediate links, and high labor intensity, so as to reduce personnel dependence, high degree of automation, and improve The effect of the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

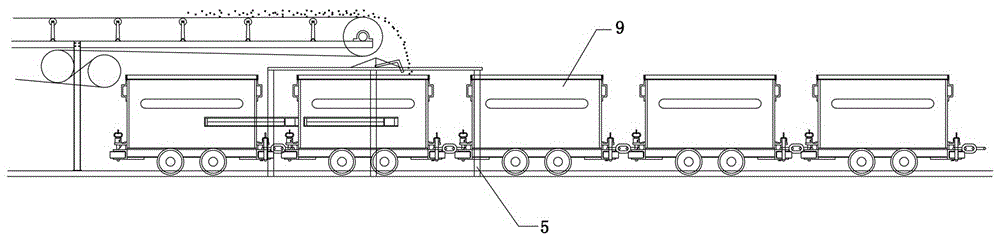

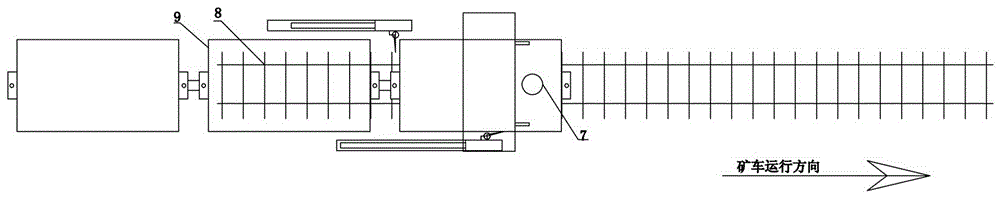

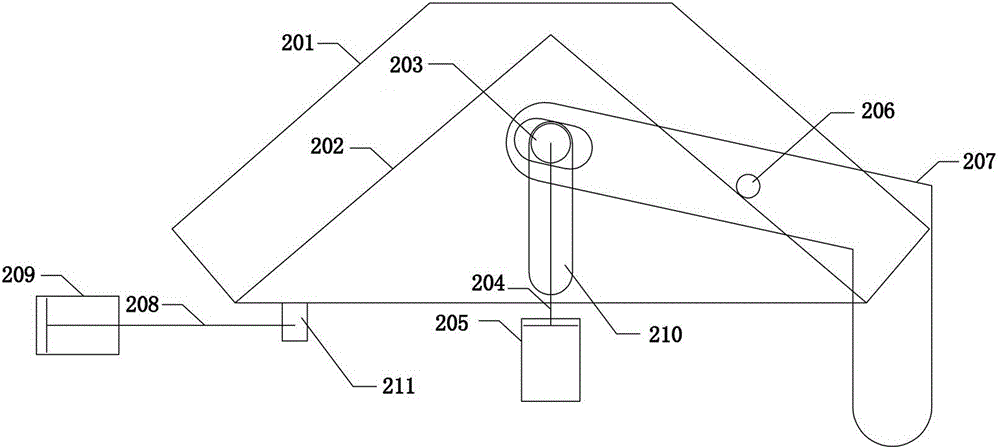

[0034] Such as figure 1 and figure 2 As shown, the present invention is a fully automatic continuous gangue extraction system used for gangue extraction at the underground rock roadway working face in coal mine production. Through various sensors, the process and state of gangue loading are detected, and the mine is controlled according to the height of gangue loading of the mine car. The movement of the car, the operation of the gangue-blocking trolley and the belt conveyor, etc., so as to realize the automatic control of the whole gangue-loading process. The system includes a mine car 9 and a mine car track 8, and legs 5 are arranged on both sides of the mine car track. Wherein the trolley system is set on both sides of the mine car, and the gangue blocking system is set on the top of the mine car. The hydraulic system provides power for the trolley system, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com