A vaned diffuser with a dovetail-shaped leading and trailing edge structure and its modeling method

A diffuser, dovetail-shaped technology, used in non-variable volume pumps, machines/engines, components of pumping devices for elastic fluids, etc. It is difficult to process the press, and it is difficult to guarantee the machining accuracy, so as to achieve the effect of simple machining, improving stable working margin and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, combined with Figure 1~4 And embodiment, the specific embodiment of the present invention is described in detail:

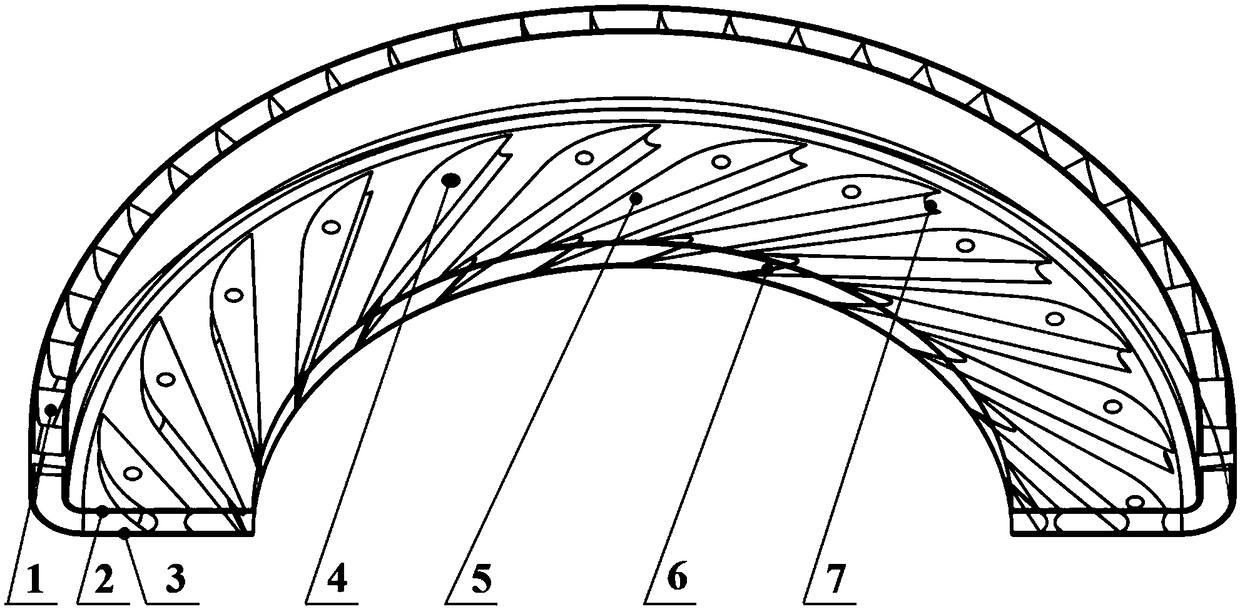

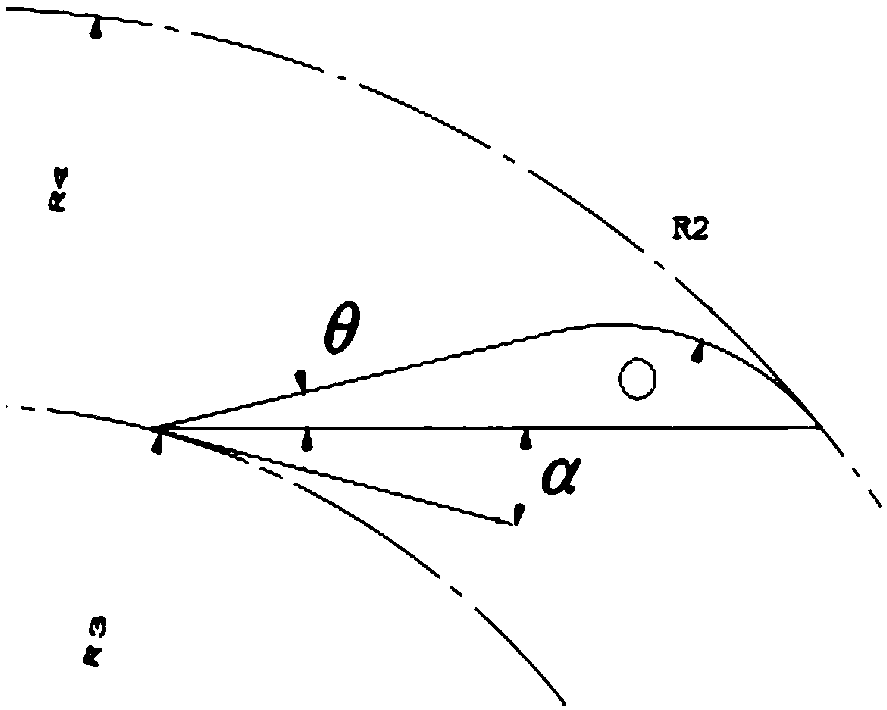

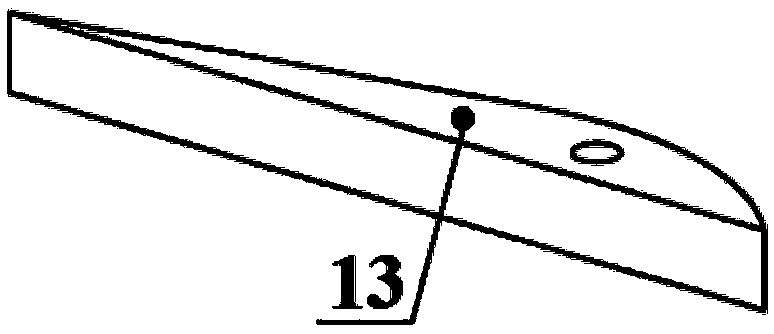

[0020] Such as figure 1 It shows an embodiment of a vane diffuser with a dovetail-shaped front and rear edge structure of the present invention, including a diffuser disc 2, a diffuser wheel cover 3, and a number of built-in radial diffuser blades 5 and axial diffuser blades. The compressor blade 1 and the diffuser connecting bolt 4 fix the radial diffuser blade 5 between the diffuser disc 2 and the diffuser cover 3, and this embodiment is suitable for a high-pressure ratio centrifugal compressor. The radial diffuser blade 5 has a dovetail-shaped leading edge 6 and a dovetail-shaped trailing edge 7 , which is creatively modified based on a traditional wedge-shaped diffuser blade 13 . The radial diffuser blade 5 is coated with an anti-scaling and anti-corrosion coating, and the anti-scaling and anti-corrosion coating is an aluminum oxide ceramic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com