A system and method for automatic measurement of forest volume based on depth sensor

A depth sensor and automatic ruler detection technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of large similarity of wood end faces, no consideration of wood end faces, and no consideration of differences in detection results, etc., to improve system adaptability and accuracy degree, avoid human subjective factors, and reduce the effect of manual training costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

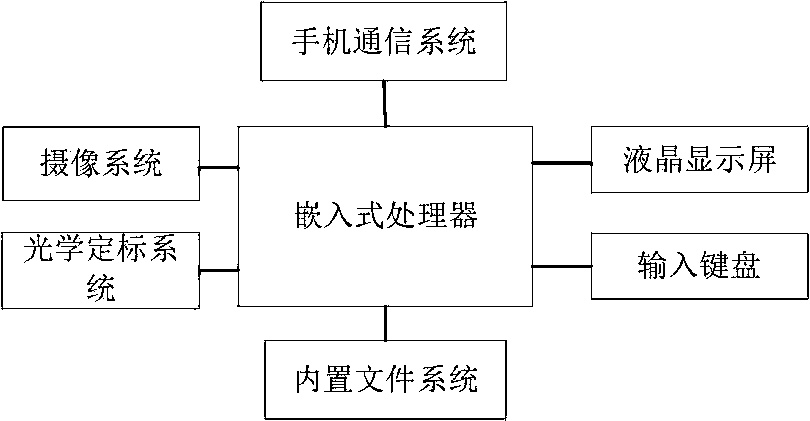

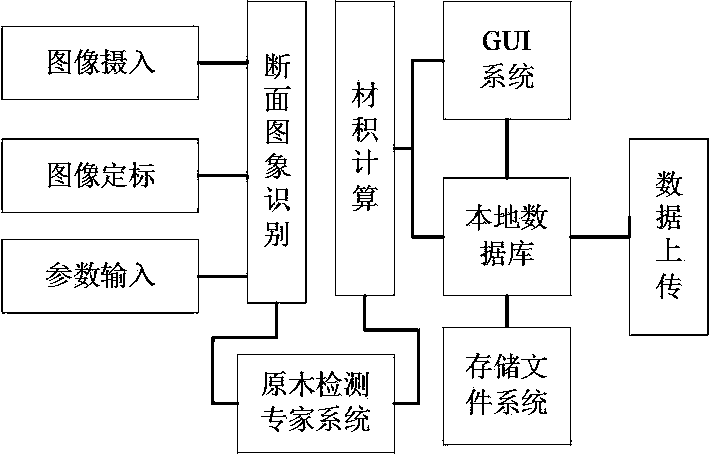

[0027] Such as figure 1 as well as figure 2 As shown, the present embodiment provides a forest volume automatic measuring system based on a depth sensor, including an embedded processing module and a camera module connected to it, an optical calibration module, a mobile phone communication module, a built-in file module, a liquid crystal display, input keyboard;

[0028] The optical calibration module adopts the imaging point spot of the parallel laser beam on the wood end surface as a pixel scale, so as to avoid the image size being unable to be measured due to the image size change caused by the change of the object distance when the image is taken;

[0029] The camera module is used to obtain the image of the end face of the wood; the camera module uses two cameras to simultaneously obtain the color image and the depth image of the end face of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com