Optical axis calibration system for laser range finder

A laser rangefinder and rangefinder technology, which is applied in the field of laser detection, can solve the problems of large experimental site area, large occupied area, and high cost, so as to reduce the cost of experimental equipment, reduce the axis adjustment site, and facilitate engineering production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

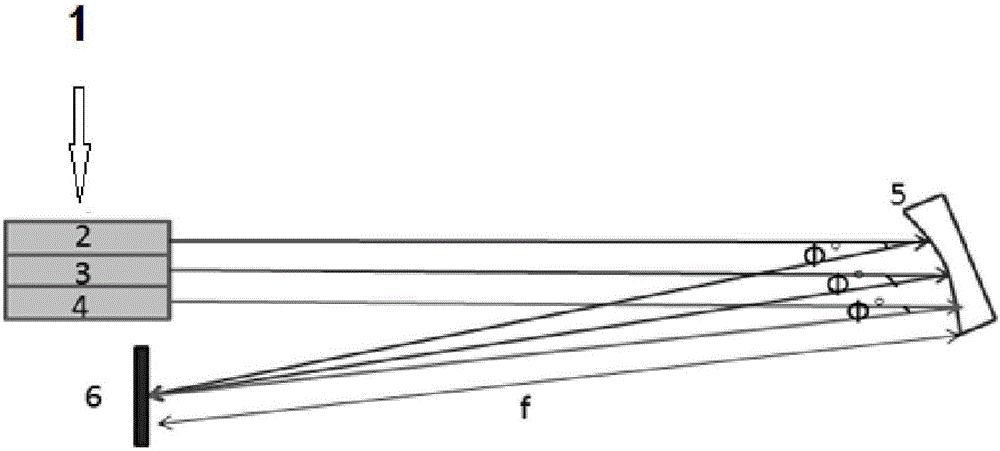

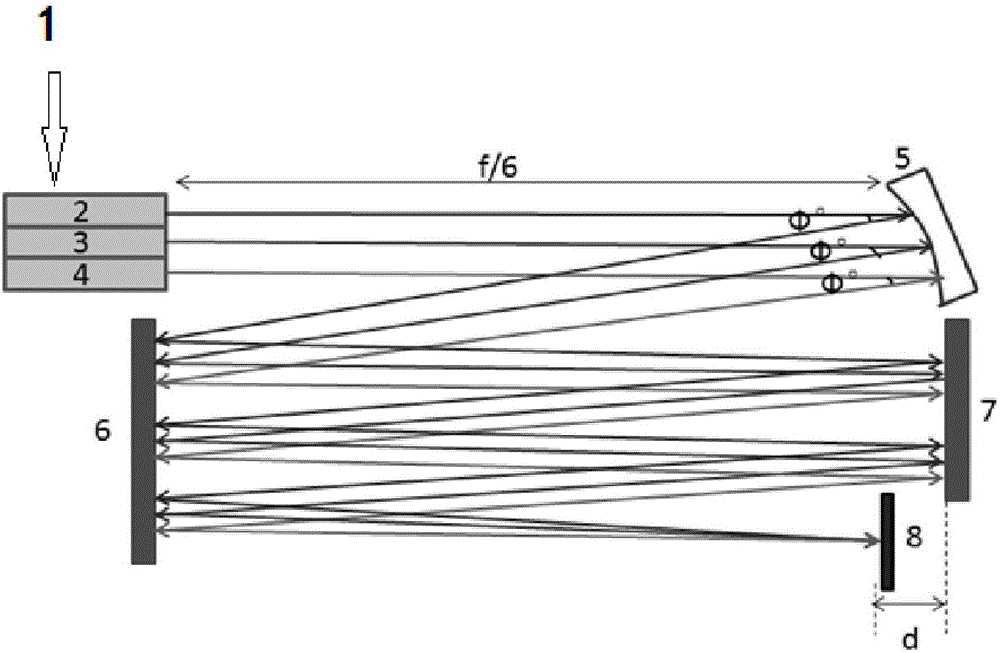

[0019] as attached figure 2 As shown in the figure, an optical axis adjustment system of a laser distance measuring machine is set on a horizontal platform as a whole when the system is working. figure 2 This is a top view of the system when it is placed on a horizontal platform.

[0020] It includes an aiming axis 2 , a transmitting axis 3 , a receiving axis 4 , a spherical focusing mirror 5 , a receiving screen 8 , a first plane mirror 6 , and a second plane mirror 7 issued by the rangefinder 1 . The spherical focusing mirror 5 is a large-diameter off-axis spherical mirror with a focal length of f, which is placed at an angle Φ with the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com