Method for calibrating on-line chromatographic monitoring device of transformer station without shutdown

A technology of monitoring device and calibration method, which is applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as unstable operation of equipment, uneven quality, poor accuracy, etc., to avoid economic losses and adverse social effects, and ensure safety and stability of the economy. The effect of running and avoiding grid accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

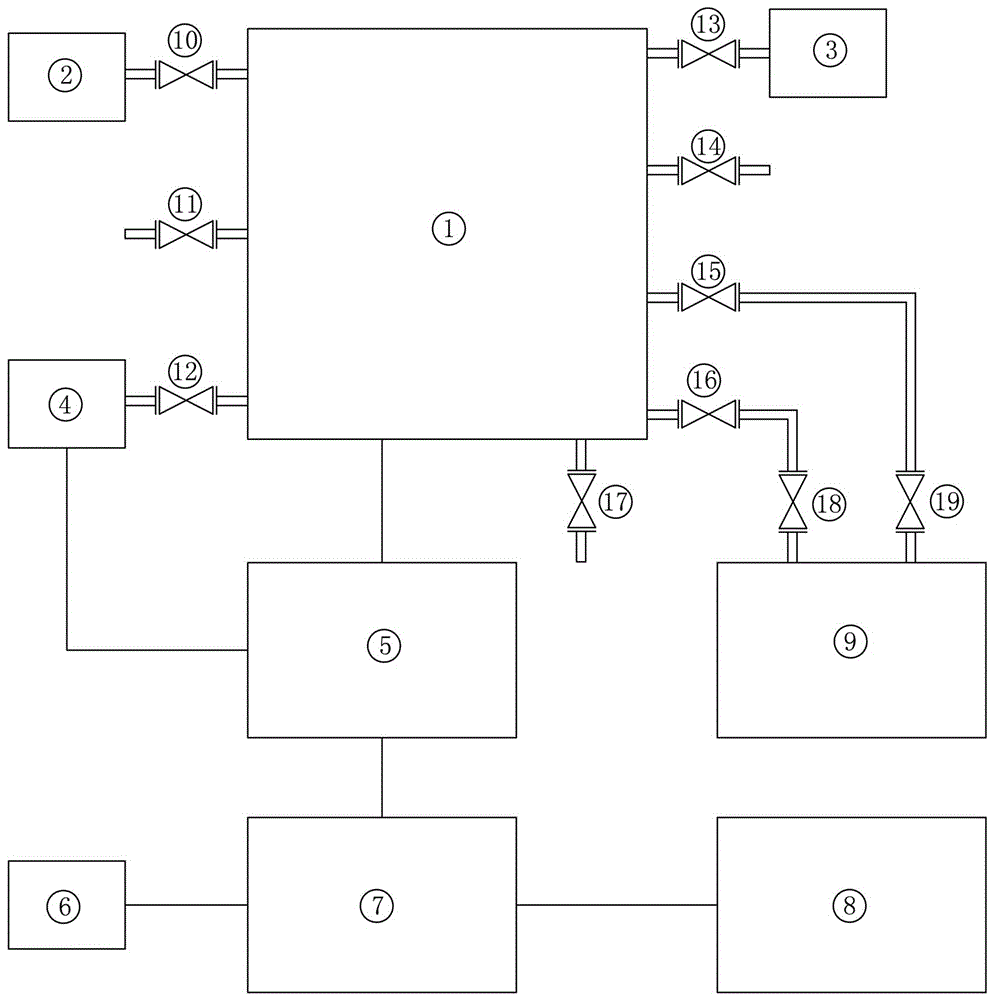

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is part of the content of the calibration report of the main transformer online chromatograph at a certain site, the details are as follows:

[0032] 1. Verification content and requirements

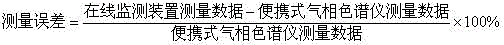

[0033] 1.1 Measurement error test

[0034] 1.1.1 Standard oil sample preparation

[0035] 1.1.1.1 After injecting new transformer oil into the calibration instrument, a certain amount of standard single-component gas (H 2 , CO, CO 2 、CH 4 、C2 h 6 、C 2 h 4 、C 2 h 2 ), fully mixed with transformer oil under the condition of 60°C in the calibrating instrument, and prepared a certain concentration of "standard oil sample containing seven components". The concentration of each gas component in the prepared standard oil sample was determined by a laboratory gas chromatograph.

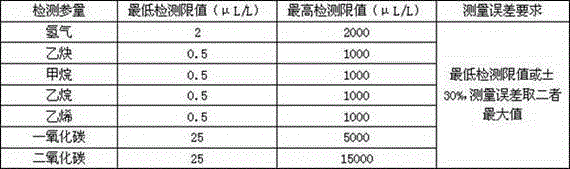

[0036] 1.1.1.2 The concentration of components in the standard oil sample shall refer to the following requirements:

[0037] 1.1.1.2.1 The lowest detection limit (allowable deviation -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com