Continuous ramming type seismic source device

A technology of ramming source and shaft connection, which is applied in the direction of measuring devices, seismology, instruments, etc., can solve the problems of delay in signal excitation and output, poor quality of reflected signals, and insufficient exploration depth, etc., so as to prolong the use time of equipment , increase reliability, and solve the effect of low excitation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

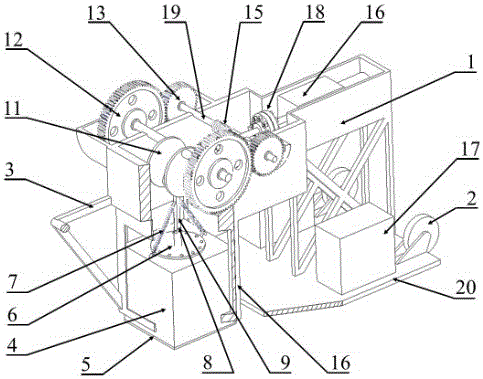

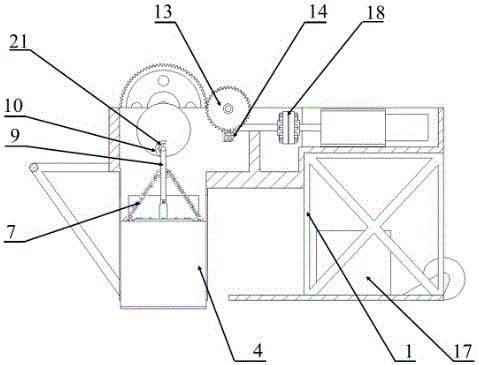

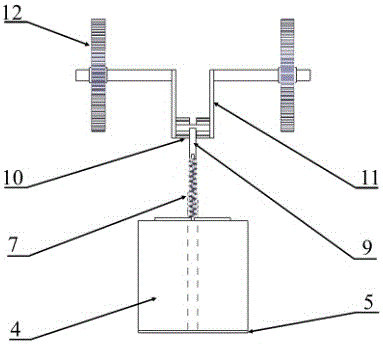

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a continuous tamping type seismic source device of the present invention is mainly composed of a frame 1, wheels 2, handrails 3, a weight 4, a shaft-connected bottom plate 5, a baffle plate 6, a return spring 7, a pin shaft 8, and a T-shaped Rod 9, semicircle arc draw-in groove 10, crankshaft 11, bull gear 12, pinion 13, worm gear 14, worm screw 15, three-phase asynchronous motor 16, counterweight 17 form. There is a central hole in the middle of the weight 4, which is fixed on the shaft-connected bottom plate 5 through the baffle plate 6; the shaft-connected bottom plate 5 is connected with the T-shaped bar 9 through the pin shaft 8; the T-shaped bar 9 is fixed on the crankshaft 11 The semi-arc draw-in groove 10 forms intermittent motion mechanism; The whole device is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com