High-precision motion platform-based multi-camera calibration method

A motion platform and calibration method technology, applied in the field of multi-camera systems, can solve the problems of difficult design of calibration objects, lack of universality, low parameter accuracy, etc., achieve high-precision measurement and automatic control capabilities, improve work efficiency, and achieve accurate calibration results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

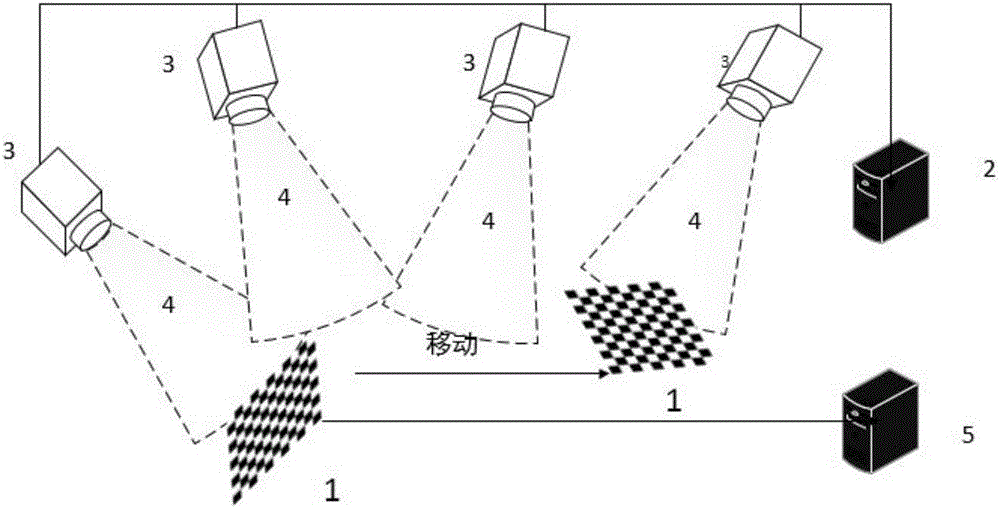

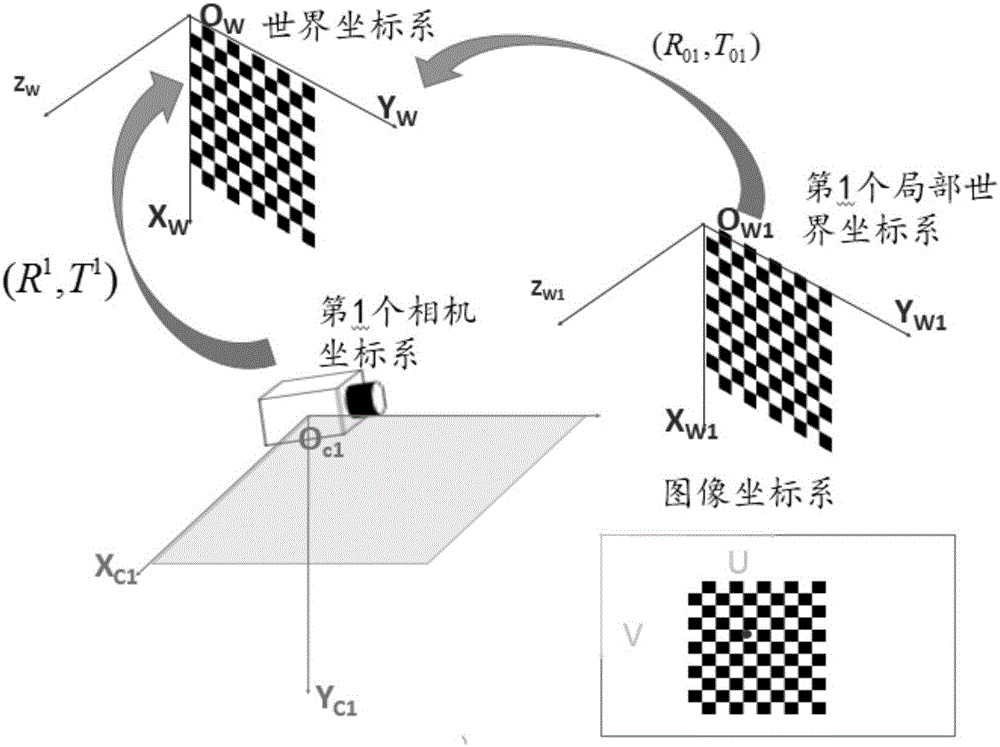

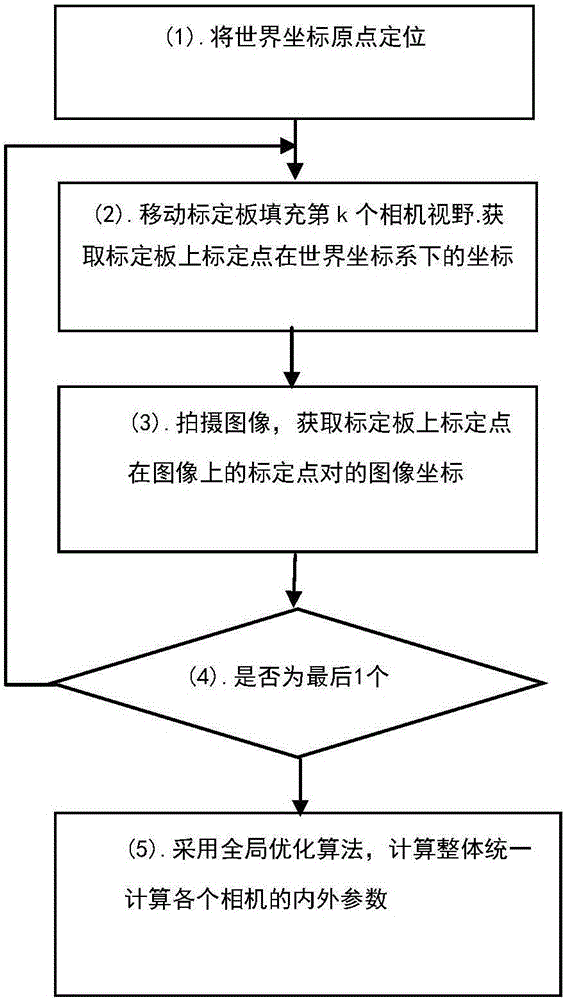

[0041] Multi-camera systems typically require cameras or cameras to capture objects from multiple angles. When the images of the object or person to be reconstructed are viewed from different angles at the same time, the 3D information of the object or person to be reconstructed can be calculated by using the calibration results of the multi-camera system to achieve goals such as motion capture. Therefore calibration is the most basic and important step of the system. The camera layout structure of the present invention can adopt a general multi-camera system structure, and there is no special requirement for the installation position and posture of the multi-camera; figure 1 As shown, the layout diagram of the multi-camera system calibration system in this preferred example, the moving rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com