A large-size sapphire crystal boat transfer device

A transfer device, sapphire technology, used in transportation and packaging, electrical components, conveyor objects, etc., can solve the problems of frequent wafer switching steps, large 6-inch substrate area, and high risk of damage, so as to avoid human body and wafer Contact, avoid artificial pollution, strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

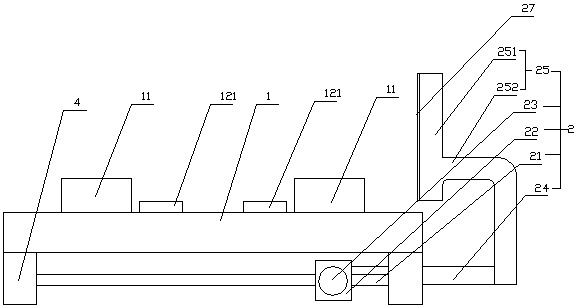

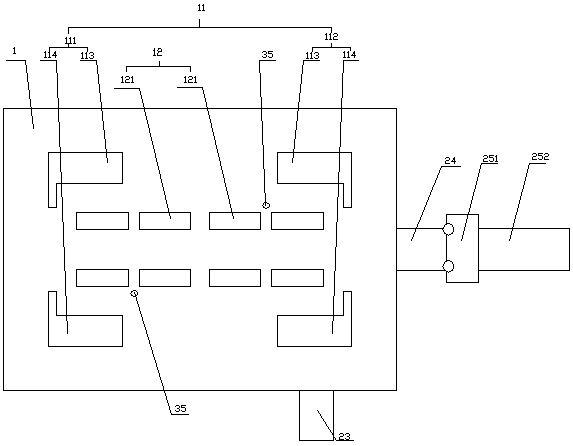

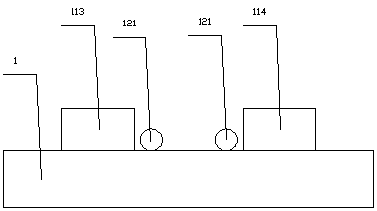

[0031] In this embodiment, the specific labels are as follows:

[0032] Assembly carrier 1, wafer boat positioning mechanism 11, wafer support mechanism 12, left wafer boat positioning mechanism 111, right wafer boat positioning mechanism 112, upper positioning block 113, lower positioning block 114, supporting block 121;

[0033] Push piece mechanism 2, slide bar 21, slide block 22, handle 23, push rod 24, push piece support 25, slide bar hole 221, push piece block 251, support block 252, groove 26, antistatic bump 27;

[0034] Crystal boat loading protection device 3, positioning lever 31, arc rod 311, rotating shaft 312, lever groove 32, cylinder groove 321, connecting rod 33, connecting rod through hole 34, movable button 35, movable button spring 36, Movable button groove 37;

[0035] Supporting feet 4 , locking protrusions 5 , locking blocks 6 , wafers 7 , target wafer boats 8 , and loading wafer boats 9 .

[0036] As shown in the figure, a large-size sapphire crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com