Novel high-capacity power nickel-metal hydride battery

A nickel-metal hydride battery, high-capacity technology, applied in the direction of nickel storage battery, alkaline storage battery, battery pack parts, etc., can solve the problems of high cost, battery power performance, safety performance decline, etc., to achieve cost reduction, simple structure, automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

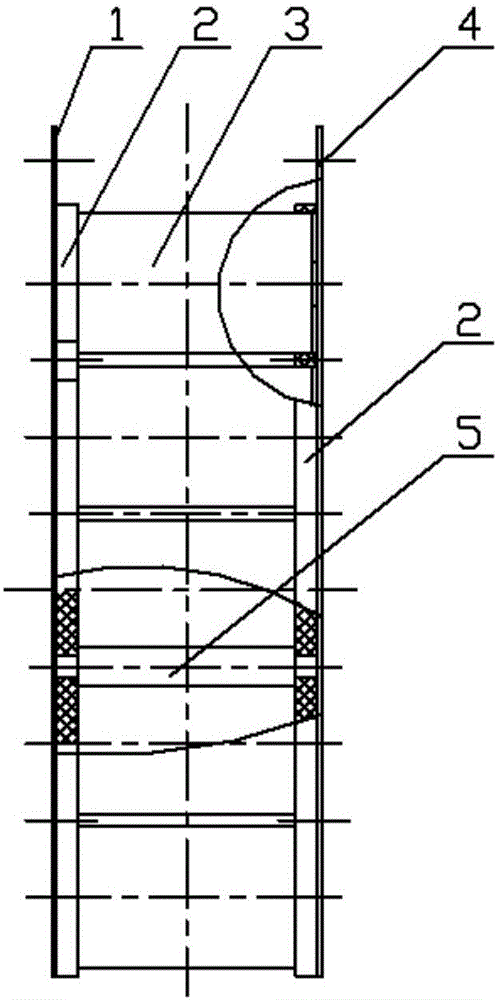

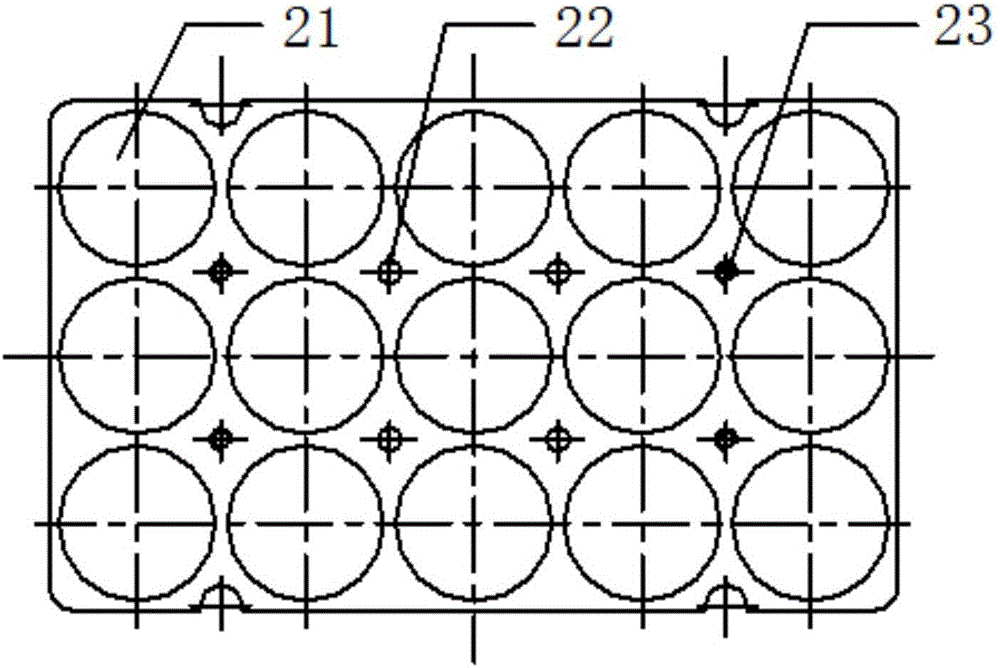

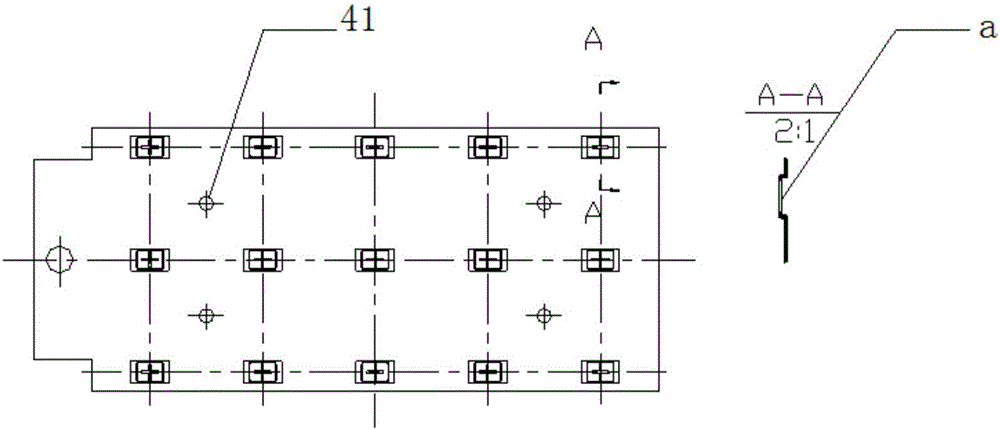

[0026] figure 1 It is a structural schematic diagram of the novel high-capacity power nickel-metal hydride battery described in the present invention. figure 2 It is a structural schematic diagram of the fixing plate of the present invention. image 3 It is a structural schematic diagram of the positive electrode bus plate of the battery according to the present invention. Figure 4 It is a schematic diagram of the structure of the negative electrode bus plate of the battery according to the present invention. to combine Figures 1 to 4 , the new high-capacity power Ni-MH battery includes a battery pack 3, two fixed plates 2, a battery negative manifold 1, a battery positive manifold 4 and a support column 5; the battery pack 3 is composed of 15 cylindrical power Ni-MH batteries 31 connected in parallel combined. The two fixing plates 2 are respectively referred to as a first fixing plate and a second fixing plate, wherein the structures of the first fixing plate and the ...

Embodiment 2

[0034]The difference between Embodiment 2 and Embodiment 1 is that the battery pack 3 is composed of 30 cylindrical power Ni-MH batteries 31 connected in parallel; there are 4 supporting columns 5; the first fixing plate and the second fixing plate The number of battery mounting holes 21 is 30; the number of supporting column mounting holes 22 and the number of positive and negative manifold positioning threaded holes 23 are 8 respectively, the number of positive manifold positioning holes 41 is 8, and the number of negative manifold positioning holes The number of 11 is 8, and the welding spot on the battery negative bus plate 1 adopts a circular concave structure. The width of the gap between the cylindrical power Ni-MH batteries 31 is 2.5 mm, and the thickness of the nickel sheet a is 0.1 mm. Both the fixing plate 2 and the support column 5 are made of insulating material ABS plastic, and the composition and connection relationship of other components are the same as those ...

Embodiment 3

[0036] The difference between embodiment 3 and embodiment 2 lies in that the width of the gap between the cylindrical power nickel-metal hydride batteries 31 is 5 mm, and the thickness of the nickel sheet a is 0.15 mm. Both the fixing plate 2 and the support column 5 are made of insulating material epoxy board, and the composition and connection relationship of other components are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com