Power distribution cabinet

A technology for power distribution cabinets and cabinets, applied in substation/power distribution device shells, electrical components, substation/switch layout details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

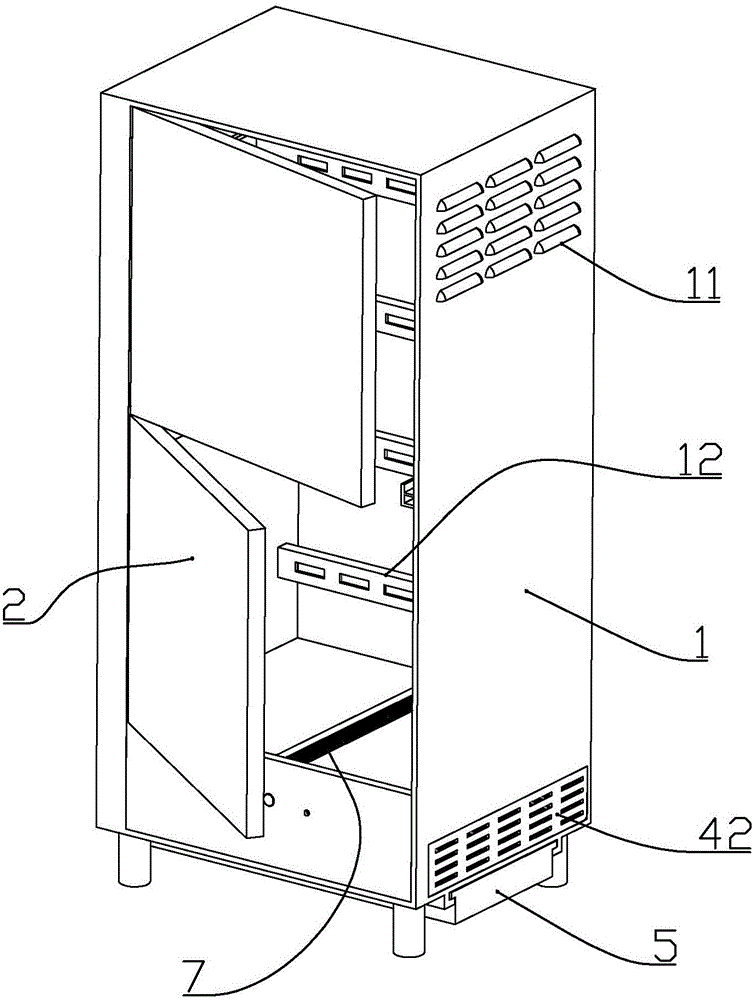

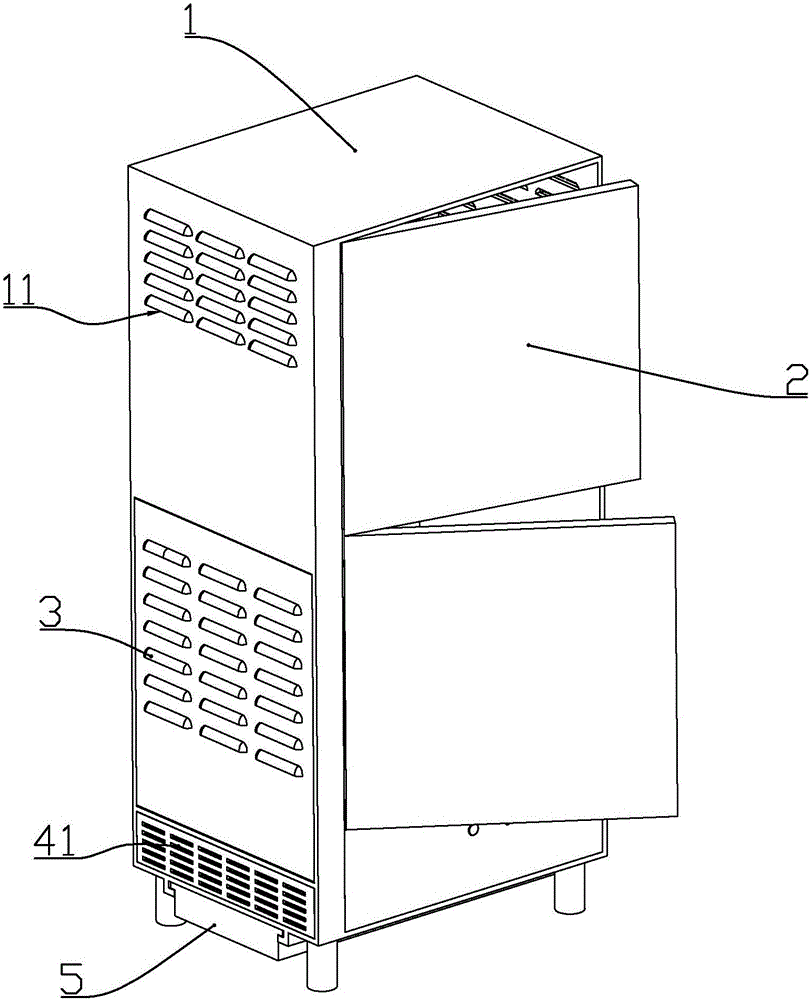

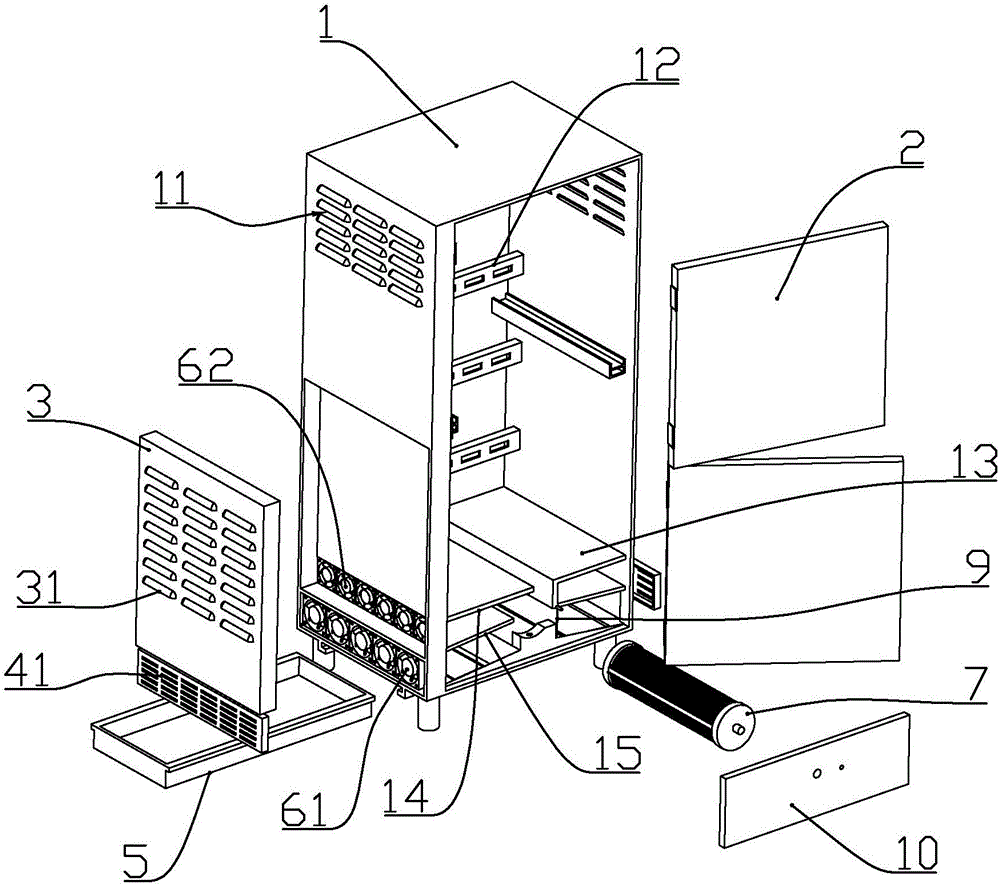

[0067] according to Figure 1 to Figure 14 As shown, the present embodiment is a power distribution cabinet, which includes a cabinet body 1 with an open front end, and a cabinet door 2 connected to the front end of the cabinet body through a hinge;

[0068] The bottom of the cabinet body is formed with a high middle and low slope plate 16 on both sides; the rear cabinet plate is located on the rear side of the cabinet body in the cabinet body, and a stepping motor is installed on the bottom of the rear cabinet plate located above the middle position of the slope plate 8. The output shaft of the stepping motor is connected with a cooling plate assembly 7 arranged horizontally along the front and back direction of the cabinet.

[0069] The cooling chip assembly 7 includes two circular end blocks 74 of plastic material, more than one semiconductor cooling chip 71 connected between the two end blocks, a condensation aluminum seat 72 connected to one side of the semiconductor cool...

Embodiment 2

[0083] according to Figure 1 to Figure 14 As shown, the present embodiment is a power distribution cabinet, which includes a cabinet body 1 with an open front end, and a cabinet door 2 connected to the front end of the cabinet body through a hinge;

[0084] The bottom of the cabinet body is formed with a high middle and low slope plate 16 on both sides; the rear cabinet plate is located on the rear side of the cabinet body in the cabinet body, and a stepping motor is installed on the bottom of the rear cabinet plate located above the middle position of the slope plate 8. The output shaft of the stepping motor is connected with a cooling plate assembly 7 arranged horizontally along the front and back direction of the cabinet.

[0085] The cooling chip assembly 7 includes two circular end blocks 74 of plastic material, more than one semiconductor cooling chip 71 connected between the two end blocks, a condensation aluminum seat 72 connected to one side of the semiconductor cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com